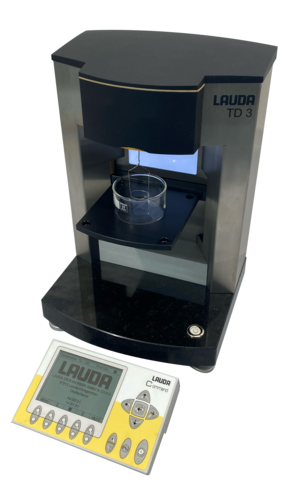

| OELCHECK test instrument: | Lauda TD 3 |

| Sample quantity: | approx. 30 ml |

| Unit: | mN/m |

| Test result: | interfacial tension between water and oil |

| Analysis for: | insulating and transformer oils |

| Brief description: | In order to determine this with the Lauda TD 3 tensiometer, a testing cylinder is filled with 20 ml each of distilled water and the transformer oil to be tested. Due to the huge differences in polarity, two phases are rapidly formed. Water, which has the higher density, forms the lower phase and the insulating oil floating above. Fresh transformer oil is non-polar. Polar components have formed in the used oil, which accumulate in the region of the barrier layer of water (polar) and oil (non-polar). The interfacial tension of the water/oil phases is influenced by the interaction of the ageing products with the water. The Lecomte Du Noüy ring, secured by a wire bracket to a scale, is lowered into the water-oil mixture. By lowering the cylinder, the ring is first drawn through the water and then through the interfacial into the oil. The force occurring during phase change at the interfacial is measured. |

| Statement: | During the oxidation and ageing of oils subject to heavy demands or which are in use for several years, insoluble polar constituents are formed. Interfacial tension can detect these in the oil. In this way, it provides information on the ageing and remaining useful life of the oil. The interfacial tension is specified in mN/m in the laboratory report. If its value has fallen sharply by comparison with fresh oil or the previous sample, then ageing of the oil has occurred. The tribologist will then recommend appropriate diagnostic countermeasures, such as regeneration or an oil change. |

| Underlying test standard: | ASTM D971 |