Automated visual evaluation

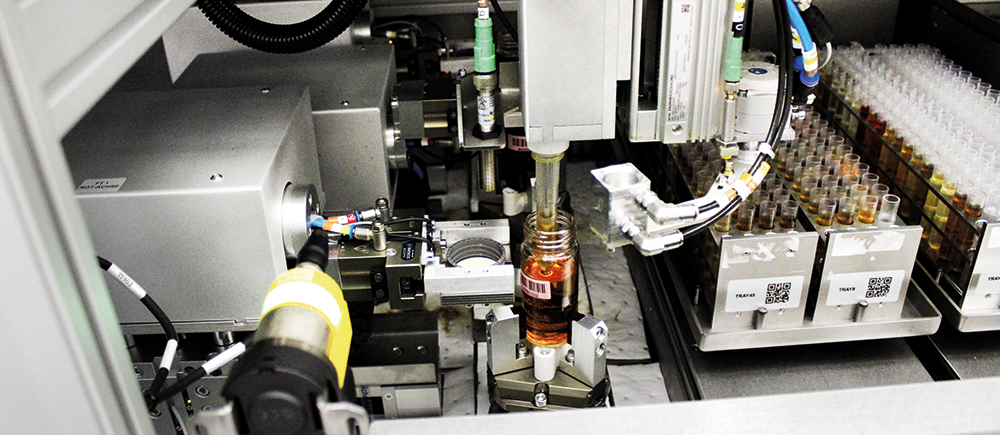

This compact testing line is only available in the OELCHECK laboratory, and nowhere else on the planet. The automated visual assessment was developed jointly by HF-Innovation GmbH and OELCHECK according to our requirements. It has been integrated into our laboratory's routine operations since the end of 2023 and proved its worth within such a short timeframe that a second facility was installed. Now, almost all samples can be visually assessed in the OELCHECK laboratory fully automatically.

At first glance, the 3.8 m long and 1,200 kg machines are quite inconspicuous. The interior contains several high-quality camera systems, special lighting equipment, motors, grippers, heating elements and a computer-assisted image evaluation. With this setup, the automated visual assessment is able to take on several tasks that previously had to be carried out by lab technicians in intricate processes. Eighty samples pass through each device in each sequence.

An den aufeinanderfolgenden Stationen:

- First, a camera system photographs the head or lid of each individual sample vessel.

-

The colour of the sample, its turbidity and the fill level of the sample vessel are read automatically.

-

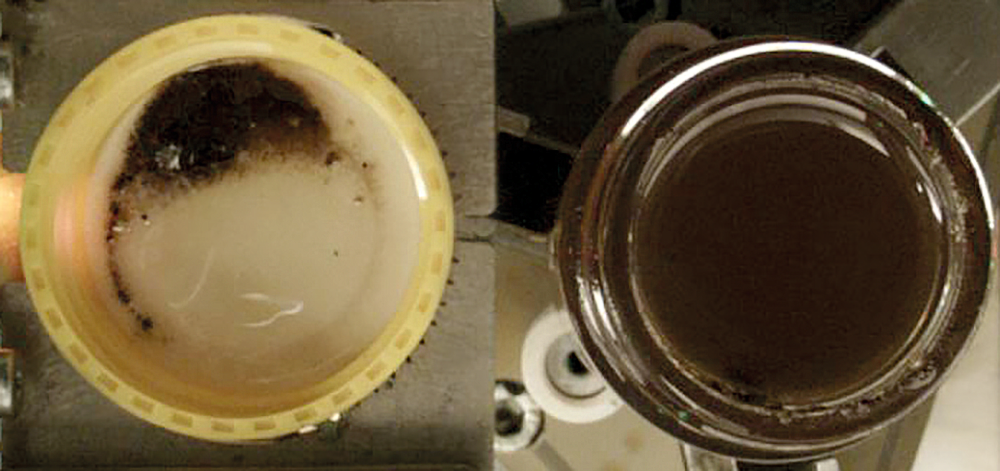

The gripper then turns the vessel over, opens its lid and puts it down with its inside facing upwards to make any deposits visible.

- At the next station, photos are taken of the inside of the opened sample vessel and the sample lid.

- A computer-assisted image evaluation determines the degree of contamination from the photo of the sample lid showing any deposits. This image evaluation has been enhanced further with the construction of the second device and expanded to include an evaluation of the brightness distribution in the lid. Contaminants covering a large surface area can now be detected with certainty.

- Water, which may be present in the sample, is detected rapidly using the splash test, aided by computer-assisted image evaluation.

- Finally, subsamples are prepared for the infrared spectroscopy and viscosity measurement. The sample vessel is then be closed and the automated visual assessment completed.

Our new testing lines are fast, hassle-free and extremely accurate. Furthermore, they don't need time-consuming maintenance. This helps staff in the OELCHECK laboratory to save time, as they no longer need to do the time-consuming, monotonous task of opening and closing thousands of sample vessels by hand.

"Automated visual assessment doesn't take a subjective approach like a human, who has to determine the colour number of a sample by comparing it to a colour scale, for example. The new devices allow the colour number to be determined, sediment in the sample lid to be observed, and objective measurements to be taken during the splash test, all of which are further benefits for all OELCHECK customers."

OELCHECKER Spring 2024, page 6