Bypass filter for engine oil?

For our mixed fleet, we need at least 15,000 l of engine oil per year. Now we are considering equipping the vehicles with bypass filters. According to the manufacturer, this virtually eliminates the need for further oil changes. Reducing costs would be entirely in our interest, of course. Even if we have to change the bypass filters several times, the switch is still worth it.

But: Is the oil really fully efficient for that long?

OELCHECK answers:

There is hardly an industrial plant that is operated without a filter. Almost all engines are equipped with filters that operate on the main stream principle. Particularly when the highest demands are placed on the purity of the oil in hydraulic systems, additional bypass filters are the means of choice. By using special filter elements, they can often absorb some water as well. For example, they make a significant contribution to extending oil change times. However, when it comes to filtering motor vehicle engine oils, things are a little different.

The tasks of the oil filters

The standard filter and the additionally attached bypass filter remove particles from the engine oil. Essentially, these are solid abrasive particles from bearings, piston rings, bushings and valves. Besides iron, aluminum, chromium, copper, tin and other metals are included. Dust particles are also removed from the oil if they have found their way into the engine oil via the intake air despite a fine intake filter. Soot particles and reaction products of oil aging can only be removed from diesel engine oil if they exceed a critical size, e.g. due to the accumulation of additives. Condensate can also form as water in the engine oil, especially during short-term operation in the cold season. However, if the engine is running regularly, the water evaporates at oil temperatures above 80 °C and thus no longer poses a problem.

Bypass versus standard filter

Standard filters are designed as tightly pleated 3- to 5-layer "depth filters". They retain particles with a size of 25 to 50 μm (ten thousandths of a millimeter). Most of the bypass filters are finer. They are said to remove particles as small as 1 μm and even smaller particles from the oil. Bypass filters are usually made of cellulose, i.e. a paper-like filter paper is wound around a support tube. This filter roll is encased in an aluminum housing.

But where is the bypass filter installed?

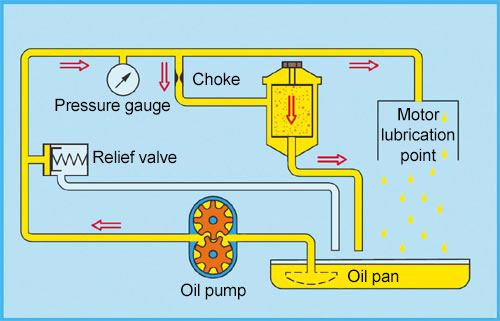

The standard filter has its fixed place. A gear wheel pump delivers the engine oil from the oil pan to the engine's lubrication points. The series filter is usually located downstream of the pump in the main flow and cleans most of the pumped oil volume before it starts its work at the lubrication points. Only when the filter capacity is exhausted do bypass valves open so that oil still reaches the lubrication points even when the filter is blocked.

A suitable location and connection options must first be found for the bypass filter. Nomen est omen! The bypass filter is not located in the main flow of the oil line, but in a branching off bypass flow. Therefore, not all the oil flows through the filter, it is on average only 5-7% of the total filling quantity.

Practical values from real life

In the OELCHECK laboratory, we have examined many oil samples from engines with an additional bypass filter and can therefore make representative statements about the degree of efficiency of such filters.

- Metals in oil almost always indicate corrosive or abrasive wear processes. We therefore take a very close look at the metal content. For engine oils, a common value for iron is after 500 Bh or at 15,000 km, for cars or at 60,000 km, and for trucks at about 80 mg/kg. With extended oil change intervals, we often find iron levels of 125 or even 170 mg/kg. The bypass filters are obviously not capable of capturing the extremely fine iron particles caused by corrosion.

- The discussion on the topic of "particulate matter" was not the last to show this: Due to the latest technology, the soot particles from the combustion process are so small that even the finest bypass filter cannot retain them. If the soot content rises above 2%, the engine oil becomes significantly thicker, heat dissipation deteriorates and the soot particles, like fine dust, can even cause abrasive wear.

- The content of additive elements remains relatively stable. Typical additives in engine oils are therefore not covered by the bypass filter.

- The viscosity usually increases slowly. The reason for this is the higher load of soot particles on the oil and increased oil oxidation. However, the original viscosity of the oil should not increase more than 3 mm2/s at 100 °C in order to maintain its functionality.

- Every oil ages mainly due to its temperature load. Engine oil is additionally polluted by acidic components that are inevitably produced during combustion, e.g. of sulfur-containing fuel, and by the formation of nitrogen oxides (NOX). These acids are extremely aggressive and cause corrosion. The BN (Base Number) states how many acidic components can be neutralized and rendered harmless by the oil. Due to the acids to be constantly absorbed and the oxidation and reaction products, the BN permanently decreases in the course of the oil's service life.

In the laboratory report, the BN is given in mgKOH/g. For engine oils, it should not fall below 40% of the initial value. A BN that is too low indicates the exhaustion of the oil in terms of its antioxidants and acid absorption capacity. The only thing that can help is a short-term oil change to prevent the oil from "tipping over", i.e. thickening, in the shortest possible time.

Bypass filters are not capable of filtering out the harmful acids that are completely dissolved in the oil. Even if we cannot detect a threatening drop in BN in the laboratory for the engine oils in question even after more than 1,000 operating hours, this does not highlight the performance of the bypass filters, but rather the quality of the engine oils and the engines.

Conclusion:

The use of bypass filters in industry makes perfect sense. However, this only applies to a limited extent to engine oils in vehicles. Bypass filters cannot remove dissolved acids or fuel contaminants from engine oils. Even the extremely small metal particles as well as the fine soot are not completely caught in the filter roll. In contrast to industrial oils, therefore, engine oils cannot be used for a much longer time despite bypass filters. Oil changes are essential.

Whether bypass filters for engine oils are economical remains to be seen. Compare the cost of traditional oil changes with that of bypass filters, their installation and replacement, and fresh oil refills. The bottom line is that the advantage is not very great.

Also consider the risk of blindly relying on the filter roll to compensate for everything. Consider how inexpensive, in comparison, an oil analysis is that informs you of the actual condition of the oil and engine. In most cases, the oil analysis even proves that the engine oil lasts significantly longer than the engine oil manufacturer has specified in its maintenance recommendations, even without an additional bypass filter.