How clean are the OELCHECK sample bottles?

We have the hydraulic fluids from our construction machinery analysed on a regular basis with analysis kit 2 for mobile hydraulics. This also includes a particle count in accordance with ISO 4406. How useful is an analysis of this kind if the hydraulic fluid is sent to the lab in a sample bottle that contains particles itself? Are the results of the analysis influenced by the transportation of the sample in the sample bottle? How clean are your bottles? Are you able to provide a statement on how many particles are present in a new sample bottle and how large they are?

OELCHECK answers

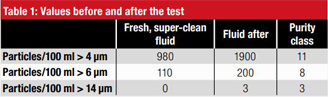

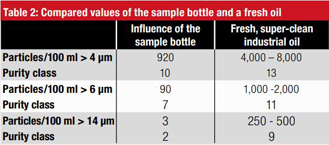

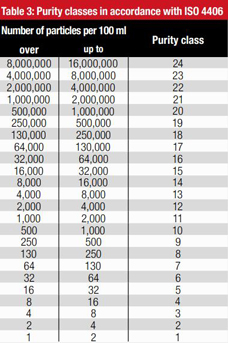

Our sample bottles are manufactured by EME International in China. This manufacturer conducts regular checks to guarantee the purity of our bottles. To provide official evidence of this purity, EME International tested the sample containers for us together with their lids. To do so, a representative number of bottles were selected, removed from their sealed, transparent protective film and filled to 90% of their volume with a particle-free liquid that is certified „super-clean“. The test bottles were then closed using their lids, before being heated together with the samples to 50°C and shaken for 10 minutes. A particle count in accordance with ISO 4406 was then conducted both with the liquid shaken in the sample bottles and with fresh samples of the liquid. The purity test was conducted using CONOSTAN PartiStan™ SCF – Super Clean Fluid. This fluid has a particle count of 980 per 100 ml at particles > 4 µm (see Table 1). For comparison purposes: The corresponding particle count in fresh oil is between 4,000 and 8,000 per 100 ml (see table 2). Following the test, the particle count obtained for the fluid was 1,900 per 100 ml. In the case of particles > 6 µm, the particle count rose from 110 to 200 per 100 ml, while in the case of particles > 14 µm it rose from 0 to 3 per 100 ml. As the oils analysed in the OELCHECK lab have a purity class higher than 13/11/9, the influence of the few particles can be ignored. A comparison of tables 2 and 3 shows that the particles in the sample bottle can increase the purity class by a maximum of one class if the value lies in the boundary region between two classes, with it being more probable that they have no effect on the purity class.

We also guarantee the particular purity of our sample bottles by using packaging that is unique worldwide: the lid and container are shrinkwrapped together, and are only unpacked and separated upon reaching the customer and shortly before use. This is why it is especially important that you use our pre-paid analysis kits, because a meaningful analysis begins with professional sample extraction and storage. Even containers that you wash before using them as sample containers may be contaminated through the very process of cleaning with particles that could influence the results of the analysis. Our analysis kits provide you with the proper „tool“ that allows you to send your sample to us reliably and easily. In addition to the sample bottle, it includes a Sample Information Form with a detachable lab number and an addressed returns envelope with a UPS return delivery form.

Why you should determine the purity class of an oil

Approximately 80% of hydraulic system failures are caused by impurities in the hydraulic oil. That‘s why OELCHECK examines the purity of hydraulic oils with particular precision when conducting a particle count. A particle count is also advisable for oils from roller bearings due to the fact that solid contaminants in the oil can influence the bearing‘s service life. The purity class should also be determined for oils from plants that pose especially stringent requirements in terms of service life and availability. After all, maintenance work on facilities such as wind turbines can end up being extremely expensive. Do keep in mind, however, that we can only provide a meaningful diagnosis from samples that reach us in a clean sample bottle.

OELCHECKER Spring 2019, page 8