VKA-Test

Oils and greases that have to withstand very high pressures and loads are already tested for their suitability during the development phase. The targeted use of the right base oil and additional use of special active ingredients (e.g. EP additives) should reduce wear at high surface pressures (often in the mixed friction area). Lubricants in use should also be regularly checked to see whether they still meet the high requirements. With the VKA test, either the yield and welding force or the wear/friction characteristics are determined by measuring a wear cap according to DIN 51350. The higher the welding force or the lower the wear characteristics of an oil or grease, the better its wear protection under pressure load. To carry out this test, Oelcheck uses a four-ball apparatus (VKA-110) from Hansa Press.

Table of contents

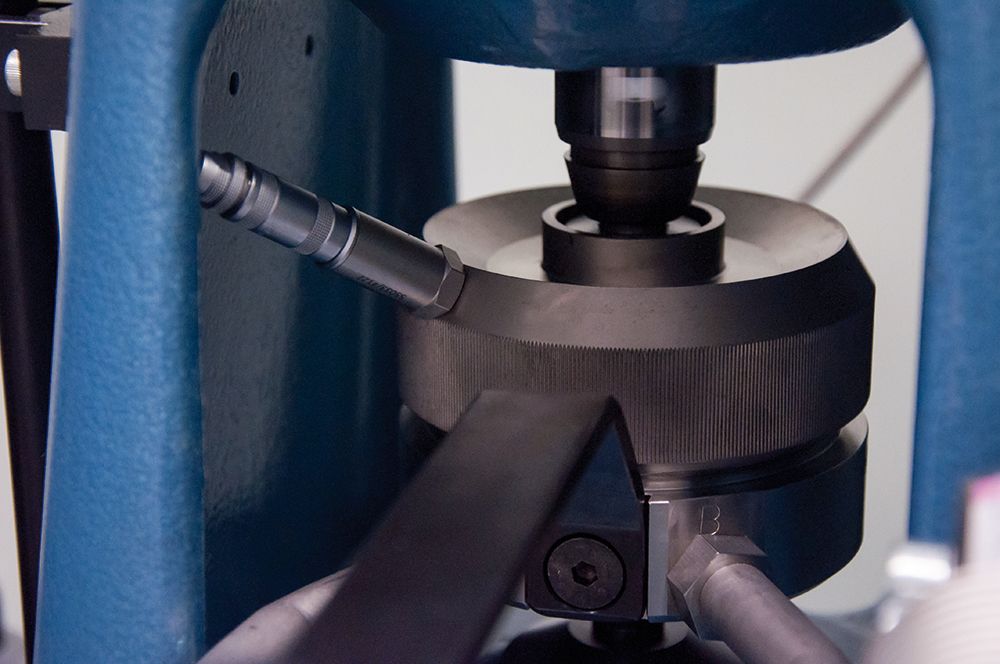

The four-ball apparatus in detail

The four-ball apparatus consists of one rotating ball and three stationary balls identical to it, a drive unit and a load arm which carries test weights. The chrome-plated steel balls that it uses are standardised. The three stationary balls are held in a cup. The lubricant to be tested is added to the cup until the stationary balls are completely covered (approx. 10 ml). The cup is prevented from rotating by an arm supported on the housing. The rotating ball is held on a vertically mounted test spindle which is located above the ball cup. A lever mechanism is used to apply the test load, which can be varied according to the weights applied and the length of the lever. The test load is applied directly to the cup via a vertical ram, and the stationary balls are pressed against the rotating ball. The test spindle, which is driven by an electric motor, rotates at 1,450 min-1. If the test balls seize up, thereby preventing rotation, the power supply is automatically cut off. The torque can be recorded continuously.

Determination of good load and welding load

When determining the welding force, the test force is increased in stages until welding of the balls occurs. This test takes 60 s for each step. The good load is the highest level at which welding has not yet occurred. The welding force, on the other hand, is the level at which welding has occurred. For the good and welding force, the VKA value is given in N (Newton).

Determination of the wear characteristics (= hourly test)

The so-called "hour test" is used to determine the long-term behaviour of different oil types or of extreme pressure (EP) and anti-wear (AW) additives. The running ball rotates with a moderate load of e.g. 150N or 300N for one hour on the stationary balls. The size of the wear domes formed on the three standing balls is given as the mean wear diameter in mm. Although the situation in the test device can only be transferred to practice to a limited extent, the VKA test is an important basis for assessing the lubricating effect of a lubricant under high pressure load. With the simple and inexpensive test, direct conclusions can be drawn about the performance of the oil or its EP and AW additives.

KRL test to determine shear stability due to viscosity change

VI-Verbesserer, die vor allem in Mehrbereichsmotoren- und Hydraulikölen zum Einsatz kommen, können durch den Betrieb stark geschert werden. Das Öl wird dadurch im Laufe der Zeit dünner. Mit dem Kegelrollenlager-Test (kurz: KRL-Test) wird mit dem Vierkugel-Apparat die Veränderung der Viskosität, die mit der Abnahme bzw. „Zerscherung“ der VI-Verbesserer einhergeht, erfasst. Zur Durchführung des Tests wird statt der Kugeln ein Kegelrollenlager eingesetzt, das mit ca. 40 ml Öl gefüllt wird. Das Öl wird mit dem rotierenden Kegelrollenlager bei einer Temperatur von 60 °C und einer konstanten Belastung von 5000N mit den 1450 1/min über eine Zeit von 4, 8 oder 20 Stunden im Tauchschmierverfahren geschert. Als Ergebnis wird der relative Viskositätsabfall bei 100 °C in % angegeben.

Die Tests mit dem VKA-Gerät sind nicht standardmäßig in den all-inclusive Analysensets von OELCHECK enthalten. Sie können den VKA-Test und den KRL-Test bei Bedarf als Einzeltest hinzubuchen.

OELCHECKER Winter 2017, page 3