Air content and air-release properties

Year of publication: 2007

How much air is in my oil?

We are repeatedly asked this question, in particular when examining hydraulic and turbine oils, but also increasingly in the intended use of online sensors.

Unfortunately, however, there is no straight answer to this question, because air is contained in every oil. Even in completely transparent oil, in which air cannot be seen in the form of air bubbles, approx. 8 to 11 % can be present in the form of "dissolved air". It depends on its saturation behavior how much air a fresh oil can absorb. This is significantly influenced by oil temperature, oil type, viscosity, pressure in the system, additives and other factors.

Air that no longer remains dissolved in the oil, for example because the air absorption capacity decreases with increasing temperature, forms bubbles. These have a negative effect on the lubricating properties, among other things. If air bubbles form between two friction partners, no lubricant film can form at this point. Pressure fluctuations can lead to a so-called diesel effect or cavitation. Particularly in hydraulic applications and in the lubrication of plain bearings, this generates wear in the form of erosion particles.

The amount of air dissolved in the oil cannot be readily determined. Once visible air bubbles have formed in the oil at operating temperature, the exact determination of the air content does not help much in solving the problem. Due to dwell and storage times on the way of a sample to the laboratory, the air content can change so much that a meaningful evaluation of the value is no longer possible.

Determination of air-release properties (LAV) at 50 °C

In order to be able to nevertheless make a statement about the behavior of air in oil, a detour is taken. The air-release properties (LAV) are determined. The air-release properties (LAV) inform about the ability of the oil to release injected or dispersed air.

200 ml of the test oil is poured into an impinger bottle, i.e. a special glass gas-washing bottle designed to collect air pollutants and particles in liquids. After determining the density of the oil at rest, preheated air is injected at a constant pressure for 7 minutes at an oil temperature of 50° C. In this process, the oil is brought into contact with the air via the gas-washing bottle. As many finely dispersed air bubbles form in the process, the oil becomes increasingly cloudy. After the air supply is terminated, a continuous density measurement is started, which indicates the density of the oil-air mixture every 10 s after the standard-compliant waiting period of 60 s.

The waiting time between the end of the air injection and the start of the measurement is required to convert the impinger so that the density can be determined via a hydrometer suspended from a balance using the buoyancy principle. The air bubbles have caused the oil to foam and the volume has increased. That is why the specific weight, i.e. the density, has also decreased.

After turning off the air supply, the air slowly degasses from the oil. The light air bubbles rise up in the oil in the process. This makes the oil "heavier" and the density value increases. When the density has approached 99.8% of the initial value, the measurement is finished. The amount of time in minutes required to reach this point is referred to as the air-release properties. This procedure is described in DIN ISO 9120 and ASTM D3427.

Air content and air-release properties (LAV) at 80 °C

The LAV at 50° C, the operating temperature of turbine and hydraulic oils, is an important indicator of how much worse the oil has become as a result of practical use. However, for oils used in turbo clutches or automatic transmissions, the temperature is not sufficient.

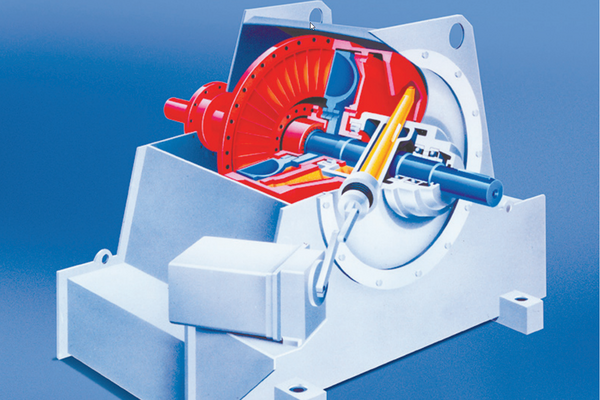

A typical case are turbo transmissions, which enable locomotives to start up "softly," for example. They have to transfer the power generated by the diesel or electric units to the rail. The fluid transmissions, some of which are multi-stage, consist of hydrodynamic torque converters and retarders. Real all-rounders that clutch, shift and brake. They are filled with up to 350 liters of thin-bodied, usually oil with special additives. It is in use almost non-stop and exposed to the highest stresses. Increased oil oxidation and degraded drive performance due to too much air in the oil can become problematic. They can also become the cause of wear in these transmissions, which are therefore often continuously monitored by oil analysis.

So for some applications, it is more important to know how quickly and completely the air outgasses the oil, not how long it takes overall:

- Oils in fluid couplings or automatic transmissions have very high circulation rates. The drive power is only transmitted via the oil. Air-containing oil results in poorer power transmission.

- For sensor development, the assessment of the air content, the "degree of foaming", is of interest. Air in the oil changes most of the oil parameters that can be determined with sensors. Knowledge of the additional air volume present in the oil makes it possible to calculate a correction factor for sensors.

- The volume change due to air in the oil can be taken into account in the design of tanks and vessels. In order to be able to determine the air content in the oil, OELCHECK has accelerated the conversion of the Impinger flask so that the density can be determined just a few seconds after the air supply is shut off and not after one minute. Thus, it is possible to plot a density curve starting after 25 s in addition to the standard air-release properties (LAV) specification. The density determined after 25 s is used in relation to the initial density of the oil to calculate the percentage amount of air remaining in the oil.

To realize practical operating temperatures, oil and air temperatures are raised from the usual 50 to 80° C. In addition to the temperature of 50 or 80° C and the specification of the air-release propertiesvalue in minutes, the air content is also specified in the laboratory report and the course over time is shown in a diagram. The special requirements of turbo transmissions were taken into account when selecting the increased oil temperature.

It turned out that a too high initial air content announces the end of the oil life after 25 s.