Automated microscopic particle counting

Clean is not pure! And even oil which looks pure at first sight can still be contaminated by the smallest particles. Particularly for hydraulic systems, oil impurities represent one of the most significant risk factors. 50-70% of all faults and failures in hydraulic and lubricant installations can be attributed to operating fluid contaminated by solid particles or by fluid or gaseous foreign substances. The level of contamination of an oil due to solid particles is reflected by its purity class. The purity class according to ISO 4406/1999 is indicated as a composite number, such as 21/18/13. The first number relates to particles >4 µm, the middle number to particles >6 µm and the number on the right to large particles >14 µm. For determining solid impurities, the deployment of automatic particle counters represents state-of-the-art technology. Most of these function according to the principle of light attenuation or blocking. A disadvantage of this technology lies in the fact that, e.g. air bubbles, droplets of water or roughly dispersed components inherent to the oil can influence counting in unfavourable situations. In order to be on the safe side in cases of doubt and to exclude these influences, we have installed a special OLYMPUS testing device in the OELCHECK laboratory: The automated microscopic particle counter with integrated image analysis software!

Do we go back to the good old microscope for counting particles in the laboratory? At first sight, it seems so. But the new device opens perspectives achieved by no other particle counting equipment, even if at the start of the particle counting there really was a conventional microscope.

Table of contents

It began with the microscope

Manual microscopic particle counting was and is extremely time consuming and strenuous. In addition, it requires a trained eye and a great deal of experience on the part of the investigator, even if at an earlier stage, when simple counting devices (totalisers) were deployed, microscopic particle counting represented an almost Herculean task for the laboratory assistant. But despite the great effort: all particles appear under the microscope. Fibres and reflecting particles are very easy to recognise. Even very dark and/or heavily contaminated fluids can be investigated in a targeted way with corresponding solvents on membranes arranged in cascade-like fashion with graduated pore sizes. The oil is diluted with different solvents or also undiluted and filtered by means of pressure or vacuum admission flow through a membrane with pore sizes of 1.2 µm, 0.8 μm or 0.45 μm and a diameter of 47/50 mm. The observer can then either manually „count“ the particles extracted on the filter membrane under the microscope or assign them to a purity class by comparison with representative images. Based on investigations with the microscope, additional qualitative statements may be made on the appearance, and in some cases, the origin of the detected particles.

The principle of the light blockade - milestones and the current state of the art

As an alternative to laborious manual particle counting with the microscope, particle counting was automated. For this purpose, the first laboratory devices were developed during the 1970s. Most of the particle counting devices currently used in lubricant analysis function according to the principle of light attenuation or light blockade and use laser diodes as a light source. Two types of device are deployed here.

Liquid particle counters with optical sensors (APC)

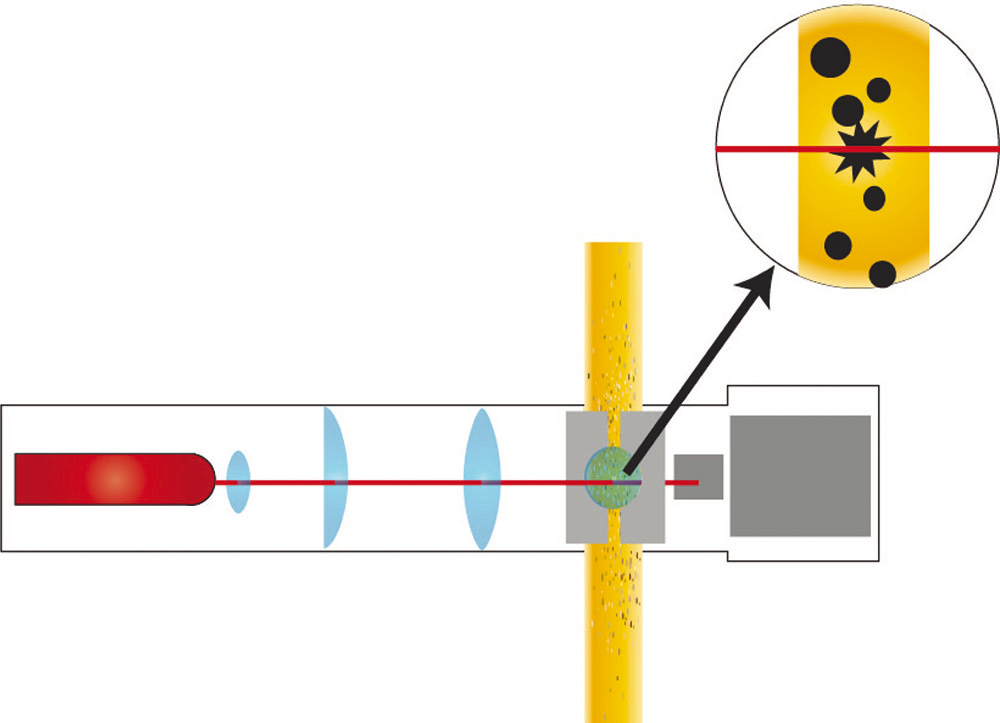

A laser diode serves as a light source for particle counting. A photocell receives the impinging light. The larger the particle, the larger the voltage drop generated by the shaded area on the photocell. The devices are calibrated with a test liquid and pre-defined test pollution according to ISO 11171 and/or 11943. A precondition for a correct determination is that the particles pass through the light beam in sequence, in order to avoid overlap in the measurement cell. In this method air bubbles and water, or silicon droplets can adulterate the result.

Liquid particle counter with imaging techniques (OPA)

For counting particles in oils, OELCHECK uses a significantly improved method, optical particle analysis (OPA). During the investigation, the oil streams uniformly through a cell developed between two glass plates. The particles are scattered in the cell and illuminated by laser light. A high-speed high resolution camera „shoots“ images of the particles. The size of the particles can be computed by means of the pixel count. No calibration of the counter is necessary during this evaluation on the basis of a defined pixel size. The optical particle analysis procedure which we presented in detail in ÖlChecker Summer 2002, categorises individual particles and their formation mechanisms on the basis of particle form. On the basis of the image capture of the particle outlines, the particle is categorised by form of origin. With the aid of assignment to different wear mechanisms, significantly improved evidence can be obtained on the state of wear of the installation.

Test devices which function in accordance with the principle of light blockade or attenuation, nevertheless have the disadvantage that, e.g. air bubbles, water droplets or roughly dispersed components inherent to the oil can influence the count (for further details, see QUESTION TIME on page 8). As a rule, this technology cannot be used for liquids deployed as a diphasic mixture, such as HFC liquids or mineral oils, the application of which entails the permanent entry of water, depending on the process.

The differential pressure procedure: a compromise solution

As an alternative method, the differential pressure procedure was introduced at the end of the 1980s and early 1990s. The decisive advantage of this technology lies in the fact that neither air bubbles nor water droplets and/or where relevant, the clouding of fluid caused by them lead to the distortion of the results. The devices designated mostly as „particle monitors“ function according to the screening principle. The differential pressure increases or the volume flow decreases as a function of the particles accumulated on a filter. The pore size of the screen is 5, 10 or 15 μm depending on the manufacturer of the device. Pressure or volume flow behaviour is evaluated by comparison with variously contaminated reference oils. In this way, classification by purity class is possible. Particle monitors on the basis of the screen blockade are designed in a highly user friendly way, but do not fulfil most specifications which require information on the particle count for the respective size.

New to OELCHECK - automated microscopic particle counting

The automated microscopic particle count with integrated image analysis software newly installed in the OELCHECK laboratory, is a method in which the described negative influences do not result in any distortions to the results and which capture all of the particles on an individual basis. This is offered as a special investigation and is deployed, e.g. when the optical particle analysis generates results which can only be interpreted in a conditional manner or if residues from a filter or sludge-like sediments are to be analysed.

In addition to the categorisation in the conventional ISO 4406/1999 purity classes, the results of the OLYMPUS special microscope also allow qualitative statements. Reflecting, e.g. metallically bright, coloured particles or fibres can be registered and evaluated separately. Through the use of adequate solvents and dilution conditions in preparing the test membrane, interfering liquid components inherent to the oil may be separated. This allows, e.g. additive-related influences on the count result to be excluded. The automated capture of the particles and rapid processing using a high-resolution camera and specially developed image analysis software guarantee a precise analysis which only takes a few minutes. The elaborate manual microscopic count may be omitted. This opens entirely new perspectives for particle analysis.

The use of various solvents and adapted dilution conditions in preparing the sample offers, e.g. the possibility of keeping special active substances, dispersed depending on function, away from the membrane. This new method may even be deployed for non-homogeneous fluids which may contain several fluid phases (e.g. HFC fluids) and which often tend towards colouring or formation of deposits on the filter membrane. Through the targeted choice of threshold levels for particle recognition and the brightness adjustment of the incident light source, included particles may be safely detected.

Calibration with test dust, prescribed for fluid particle counters, may be omitted from the microscope. The particles are measured two-dimensionally, with the longest extension appearing as the particle size in the laboratory report according to ISO 4406/1999. Possible deviations on the basis of the differences between test dust and actual impurities need not be considered.

Examination procedure

According to the lubricant and deployment, the sample is diluted with the necessary solvent. 50 ml of the homogenised sample is filtered through a dried 47 mm filter membrane. Following this, the membrane is flushed with filtered solvent, dried and the weight gain due to the pollution determined. The microscope has a motor-operated cross-sliding table controlled by software, on which the membrane is stretched in a special holder and positioned.

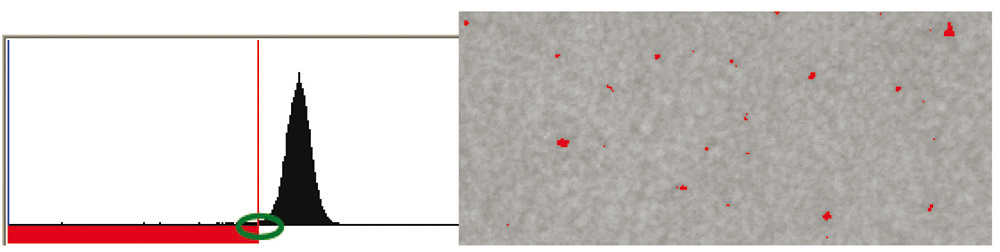

Before the start of measurement, focus points are defined and a selection of a representative membrane section made for analysis. After defining the threshold value for distinguishing between particles and the background membrane, the sample is „raster scanned“ microscopically in incident light mode. A high-resolution CCD camera captures all of the particles which appear darker for the grey value. Through image analysis software, these are measured and categorised by their longest extension.

The display of results in the OELCHECK laboratory report

Specification of the purity class is carried out as normal according to ISO 4406/1999. In any case, for the microscopic count, only two classes are specified, which can be calculated from the count of >5 µm and >15 µm sized particles. In order to ensure an easier assessment of the particle distribution, the particle numbers in the >2, >5, >15, >25, >50, >100, >150, >200, >500 µm gradations are represented in tabular and graphical form in the laboratory report.

A colour photograph documents a representative section of the test membrane, being generated with the use of polarised light. The laboratory report also includes an image of the largest detected particles with a 100x enlargement.