Dissolved Gas Analysis

Year of publication: 2011

Test standard: ASTM D3612-02, VDE0370-9:1994-06, VDE0370-7:1999-12 Measuring range: 0-10,000 Unit: μl/l (ppm) Sample volume: 5 ml Determined: Dissolved gases in transformer oils H2, O2, N2, CO2, CO, CH4, C2H6, C2H4, C2H2

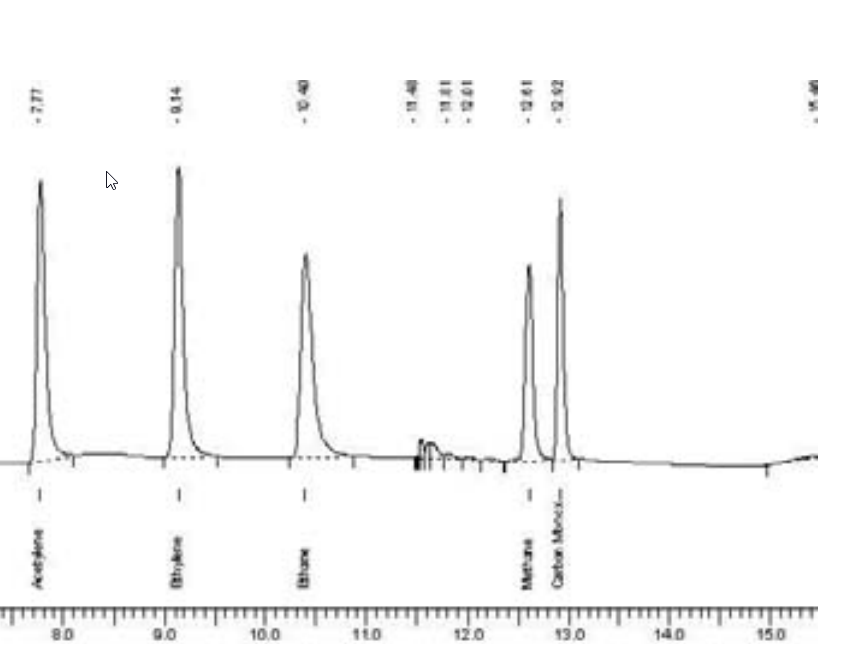

The analysis of gases present in the transformer oil in dissolved form is carried out with a PerkinElmer Clarus 680 with a TurboMatrix 40 Headspace Sampler, specially developed for this purpose. This analytical procedure is used to evaluate defects in electrical equipment with the aim of initiating countermeasures in good time. Dissolved gas analysis is the most frequently performed method for monitoring transformers. It offers many advantages and not only for the detection of defects:

Type of | Cause of defect | Effects, appearance |

PD | Partial discharges | Paraffin wax formation on the paper insulation |

D1 | Low energy discharges | undissolved small carbon particles in the oil, larger holes in the paper insulation |

D2 | High energy discharges | Carbonisation of the oil, destruction of the paper insulation, molten metal |

T1 | Thermal defects, temperatures of | Oil oxidation, brownish discolouration of paper |

T2 | Thermal defects, temperatures of 300 to 700°C | increased oil oxidation, carbonisation of paper |

T3 | Thermal defect, | Oil carbonised, |

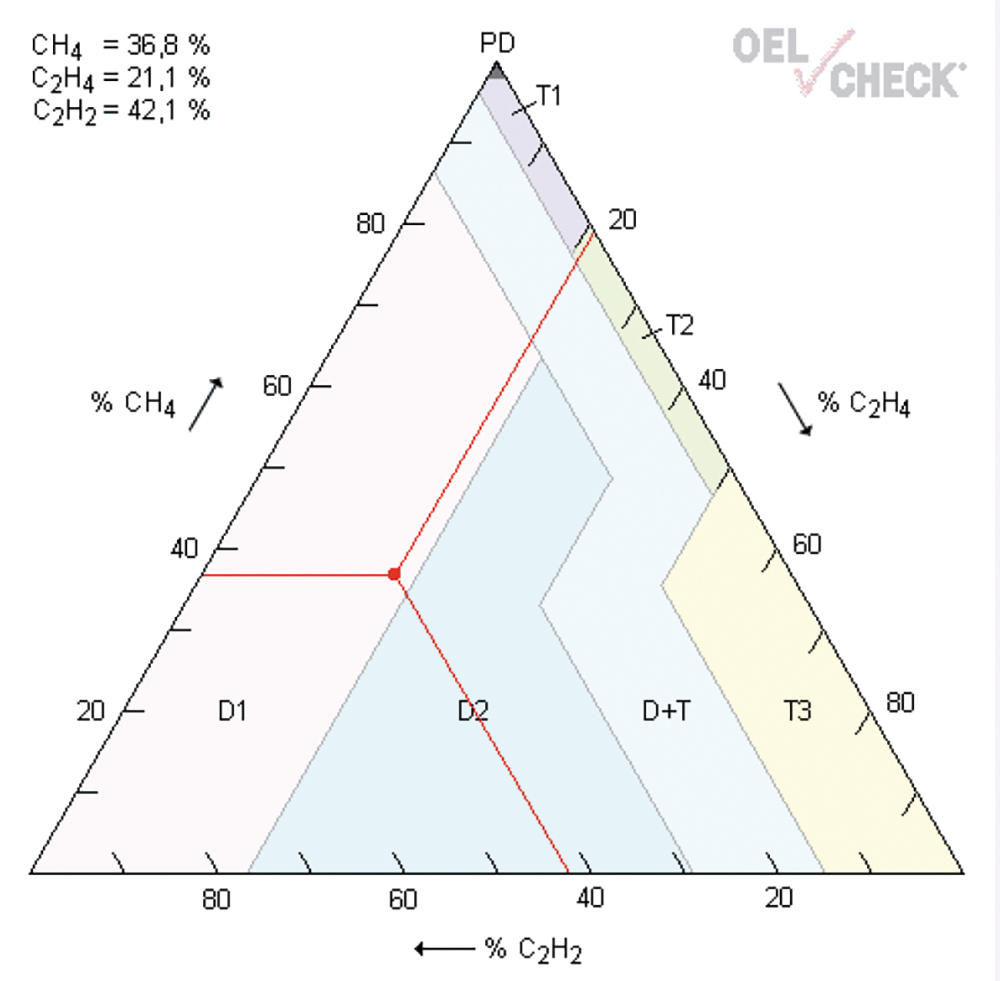

In addition to the values for pollutant gases, the Duval triangle is illustrated in the laboratory report. This allows the visualisation of the type of defect present. At increased concentrations, a summary statement can be generated using this tool.

Example: in a DGA analysis, the following percentages were calculated based on the ppm values: Ethylene (C2H4) = 36.8%, acetylene (C2H2) = 21.1%, methane (CH4) = 42.1%. These values are entered into an isosceles Duval triangle parallel to the sides. The point at which the three lines intersect lies in a field with the types of defect listed in the table. In this way, a conclusion about the type of defect present in the case of example = D1 can be made.

Reference values for which a more frequent analysis is advisable, if exceeded:

Gas component | 90% concentration values in µ/l | |

Hydrogen | H2 | 60 - 150 |

Carbon monoxide | CO | 540 - 900 |

Carbon dioxide | CO2 | 5.100 - 13.000 |

Methane | CH4 | 40 - 110 |

Ethane | C2H6 | 50 - 90 |

Ethene | C2H4 | 60 - 280 |

Ethyne | C2H2 | 3 - 50 |