FT infrared spectroscopy - On the trail of oxidation

Year of publication: 2000

Infrared spectroscopy is one of the most important analyses in used oil evaluation.

It is a standard feature of all OELCHECK analysis kits.

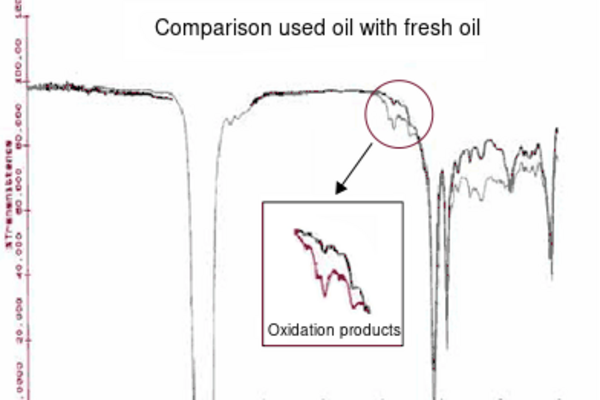

IR spectroscopy is used to detect impurities in the lubricant and to identify mixing. Furthermore, it determines the condition of the oil in terms of oxidation, nitration and sulfation. The method is based on the use of infrared light. A small amount of oil (1ml) is spread evenly on a crystal or inserted into a 0.1 mm cuvette. Infrared light stimulates the molecules of the oil to vibrate. Due to changes in the chemical structure of the oil, the molecular bonds absorb IR light to different degrees. The result is an IR spectrum as an "absorption image". Changes visible when comparing the used oil spectrum with that of the fresh oil are identified as additive degradation, impurities, aging products and oxidation. A special computer program for oil analysis translates the IR spectrum into numerical values.

Since OELCHECK has stored data from thousands of the most common fresh oils, a fresh oil is only required from the customer in exceptional cases.

By comparing the fresh oil with the used oil, IR spectroscopy provides information about oil oxidation, nitration and sulfation. Soot, fuel content and water are converted and expressed as a percentage. Glycol from the cooling water can be detected. Even with an unknown oil, IR spectroscopy delivers an amazingly good fresh oil assignment and accurate values by comparing the used oil with the fresh oils in the database via a "reverse search".

Which individual values are determined at which "bands" of the IR spectrum for the lubricant depends on the type and use of the lubricant. Below you can see an overview of causes for an IR spectrum to change and their possible effects.

Table of contents

Oxidation and aging (for all types of lubricants)

Reactions of oil molecules with oxygen cause oils to oxidize. Increased oil temperatures (above 50 ° C), catalytic impurities and intensive air intake accelerate the process.

Reasons

- Oil change intervals that are too long

- Oil sump temperature too high

- Short-term overheating

- Wrong oil, unfavorable additive combination

- For engine oils: high sulfur content in fuel

Effects

- Viscosity increase up to loss of pumpability

- Increased corrosion on all components

- Varnish-like deposits on filters and oil-wetted machine parts

- Dark coloration of the oil, often pungent odor

Water (for all lubricants)

Water enters the oil as "soft" condensate or rainwater or as "hard" tap or cooling water.

Reasons

- Condensation due to low operating temperature, "stop-and-go" operation

- Rainwater penetrates through the bungholes in barrels that stand outdoors

- Leaks, cracks or faulty seals in the cooling system

- Cleaning with steam jets

Effects

- Corrosion (rust) on machine parts

- Poor lubrication due to water droplets

- Cavitation due to evaporation at temperature peaks

- Turbidity and thickening of the oil

- Acceleration of oil oxidation

- Acid formation

Antifreeze glycol (for all oils)

In the event of cooling circuit leaks, the glycol added to the water as radiator and antifreeze protection can enter the lubrication circuit.

Reasons

- Cracks in the cooling water circuit

- Corroded solder joints on oil cooler

- Defective seals between cylinder head and engine block

- Leakage at "wet bushings”

- Refill vessel contaminated with glycol

Effects

- Extremely high thickening of the oil with increasing oil temperature and longer operating time

- Deposits in lubrication holes up to clogging

- Corrosive attack of non-ferrous metals and bearing materials, especially copper, lead and tin

OELCHECK lubricant analyses even faster and more precise with the new FT-IR devices

FT-IR equipment, which is up to date, is constantly being used in the OELCHECK laboratory. For every lubricant sample examined by OELCHECK, an IR analysis is part of the mandatory program. It provides important information about the condition of the oil and possible impurities. New and current devices are faster and provide even more precise values, especially for synthetic oils, which are being analyzed more and more frequently.

New IR instruments are also geared toward a fully automated sample changer with powerful processors and increased memory capacity. Up to 60 lubricant samples per hour can easily be analyzed. This will enable us to meet the constantly increasing number of analyses in the OELCHECK laboratory in the future as well.

In contrast to older instruments, where each sample is still applied individually to a crystal, the ATR cell, in modern instruments the oil flows into a 0.1 mm thick cuvette designed as a flow cell. Clustered infrared light is beamed through the cuvette. A detector records the vibrations of the electromagnetic bonds of the molecules present in the sample, which are altered by the IR light. The result is an IR spectrum.

The IR device compares the spectrum of the current sample with the data of an assigned fresh oil. If information on the oil type is missing, the program selects the oil whose "fingerprint" best matches the spectrum of the sample from thousands of possible fresh oils in the library created by OELCHECK. In most cases, the used oil spectrum deviates from the fresh oil spectrum at certain wavenumbers. From the band intensity or the area under a band in a given wavenumber range, the type and amount of contaminants in the oil such as water, glycol, fuel and soot, or the amount of oxidation, nitration and sulfation can be calculated using the mathematical method of the "Fourier Transform" (hence FT-IR).

With constantly updated equipment, faster searching, finer resolution of curves, and easier programming of algorithms to convert IR units of length or area become possible. By storing the spectra in the network, OELCHECK engineers can very easily make a comparison with another fresh oil or with an oil blend when creating the comment. With their experience in the field of mineral and synthetic oil IR spectroscopy, they are able to interpret the spectra accurately.