Limit values for lubricants

Limit values provide an initial indication as to whether analysis results point to a problem. However, this requires detailed knowledge of the application, the lubricant used and sometimes even the lubricant analysis itself. Important aspects of oil analysis, such as wear or oil condition, also depend signifi cantly on the duration of use. Due to different operating conditions and times, limit values are therefore often diffi cult to defi ne. The trend line is helpful here, in that it makes a more detailed assessment possible. But one point is crucial; the analytical results must always be evaluated in relation to each other. The mere consideration of individual values can lead to considerable errors in judgement. Before a tribologist can evaluate the results of an analysis, he needs a basis for his assessment. In addition to his own experience, he makes use of absolute limit values, fresh oil reference values and the trend line for this. The adjoining sample spreadsheet shows the extent to which the limit values, e.g. of elements in engine oils, can vary.

Table of contents

Where do limit values come from?

Limit values are determined by the following groups, often with very different intentions:

- Component manufacturers

- OEMs

- Oil companies

- Standards, technical groups/organisations

- Laboratories

Manufacturers of components often defi ne limit values for individual parameters which affect the performance or the service life of the component. For example, manufacturers of hydraulic components, such as pumps and valves, give recommendations for oil cleanliness. In particular, specifications from OEMs relating to warranty cases should be strictly adhered to. This is because OEMs also define limit values to identify necessary repairs and maintenance, establish general conditions for safe operation, and assist in evaluating oil analysis values. The limit values of oil companies usually relate to the condition of the oil. These are used to judge the point at which additive degradation or ageing has progressed too far, and the oil can no longer reliably fulfi l its tasks. This will guarantee that the oil still meets the necessary conditions of use at the time of the oil change. Limit values and evaluation bases can also be standardised, as is the case, for example, with ASTM. These values issued by specific organisations relate primarily to areas of application and must be examined on a case-by-case basis for their applicability. The limit values used by the OELCHECK laboratory are statistically determined and validated by experienced tribologists using historical analytical data which has been collected in the company‘s own database for more than 25 years. Special features such as oil and machine type, manufacturer and sampling point can also be included in the assessment in order to obtain particularly reliable and specific limit values. This is because OELCHECK asks for detailed information about every lubricant sample in its Sample Information Forms.

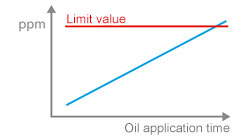

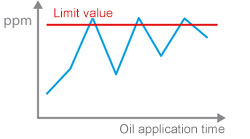

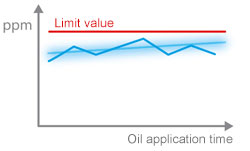

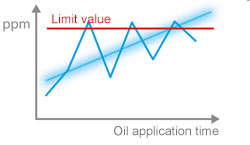

Absolute limit values vs trends

Absolute limit values provide quick and easy orientation (see Fig. 1). They are, for the most part, based on statistical analyses of machines operated under comparable conditions. As long as these operating conditions are in agreement, the limit values used are also applicable. Under differing conditions, such as start-and-stop versus continuous operation, the absolute limit values lose their significance. For all statistics, limit values must always be validated by experienced experts. If they are set too high, it may be that the lubricant has changed significantly or that the machine has been damaged without this being noticed. If they are too low (see Fig. 2), then the accumulating alarms are eventually ignored, because they occur regularly and often without good reason. Then, when an actual problem does arise, no one will respond quickly enough. Analytical results often show no ideal trend such as that shown in Fig. 1. Rather, the values (see Fig. 3) vary within a certain range, so that several samples (at least 3-4) are needed to form a trend. Only then is it possible to predict the range of values for the next result. It may also be the case that the same values for similar machines but differing trends lead to different recommendations. If the jump in a wear value is too large compared to the previous sample or in relation to the duration of use, an indication will appear in the OELCHECK diagnosis, even if the result of the analysis is below the absolute limit. Particularly when lubricants have been in use for a very long time, limit values can also be exceeded without the necessity of a warning (see Fig. 4). If the increase is in line with the trend and with the expected range for the duration of use, operation may continue without difficulty. The trend supplements the absolute limits by making more in-depth interpretations possible. This improves the predictive quality, and emerging problems are detected even earlier. This is because the trend only takes previous analysis values from the same machine into account, and so specific application conditions can best be considered. It works the same way with the doctor. He compares the results of a blood analysis with their general limit values in relation to the patient‘s personal attributes and life circumstances. The patient‘s medical history, i.e. the trend, is then used for the final assessment.

Trends – the tool of choice?

Trends are not always necessary for assessing analytical values. This is partly because enough previous sample data must be available, and you have to start somewhere. On the other hand, there are also parameters that can be comprehensively assessed with absolute limit values. Included among these are:

- Increased water content – can cause corrosion and/or cavitation, different saturation limits for the different oil types.

- Oil impurities – can lead to increased wear and affect the operation of hydraulic systems, for example.

- Elevated silicon levels – can cause abrasive wear. When assessing silicon content, consideration must also be given to the use of silicon as an anti-foam additive.

- Breakdown voltage – is examined, for example, for transformer and insulating oils.

The decision as to whether absolute limit values are sufficient as a basis for decision-making also depends on the situation. If an oil sample is taken at each oil change in order to detect necessary repair measures or emerging problems, often an assessment based on the absolute limit values is sufficient. If oil change intervals are to be optimised, the trends must always be considered when analyzing results that are dependent on the duration of use. However, even trends are not always reliable. This is due to the fact that the location of the sampling point and the way in which the sampling is performed can have a significant effect on the results of the analysis. Therefore, samples for trend analysis should always be taken in the same place, using the same method. Changes to the conditions of use or maintenance can also affect the trends.

The solution from OELCHECK

OELCHECK combines absolute limit values and trends in the evaluation of all analytical results. Our experienced tribologists rely on our in-house software SampleRating for sample diagnostics. The software displays limit values, trend curves, diagrams, photos and all the information from the information form pertaining to the current sample and machine at a glance. Each individual value is colour coded on the basis of often very specifi c limit values which have been validated multiple times. Our experienced tribologists can access data from the more than three million samples we have analysed, 200,000 machine-specific limit value tables and more than 10,000 fresh oil references. In this way, OELCHECK combines all the information and advantages of the various assessment methods in order to make a precise diagnosis.

OELCHECK laboratory reports do not include limit values; this is for the purpose of preventing misinterpretations, because values should never be considered individually, but always in conjunction with the other analytical values, the application and the lubricant used. Even a doctor does not simply hand the results of a blood test over to his patient. With their extensive expertise in the fields of mechanical engineering and chemistry, OELCHECK tribologists always assess the status of both the machine and the oil, taking all analysed values into account.

Limit values for motor oils

Element | Gasoline / diesel engine | Gas engine | Origin of the element in engine oil sample | ||

|---|---|---|---|---|---|

| mobile | stationary | stationary | |||

Wear | |||||

Aluminum | Al | 12 – 55 | 5 – 20 | Primarily from pistons, oil pump housings, oil coolers, torque converter parts, turbocharger, guide bushes, plain bearings, cylinder blocks of all-aluminium engines (together with silicon) and dust containing bauxite (aluminium oxide). | |

Lead | Pb | 10 – 30 | 10 – 20 | Usually in combination with tin and/or copper. Connecting-rod bearings, nearly all running surfaces of plain bearings, and soldered joints in combination with tin. | |

Chrome | Cr | 4 – 28 | 5 – 10 | Piston rings, crankshaft bearings, piston pins, exhaust valves, gaskets, guide bushes, chrome-plated parts and gearwheels. Fe, Al and Cr are usually found in combination with Si in engines, because dust causes the most piston (Al), piston ring (Cr) and cylinder (Fe) wear. | |

Iron | Fe | 80 – 180 | 15 – 30 | Cylinder block, cylinder head, timing wheels and timing chains, valves, valve tappets and guides, crankshaft, camshaft, rocker arm shaft, piston pins, roller bearings (with chromium), oil pump. Rare: residues of ferrocene, a fuel additive for soot reduction. Distinguishing between corrosion and wear based on the PQ index. | |

Copper | Cu | 25 – 60 | 10 – 25 | Main constituent of brass and bronze. As wear metal from oil pumps, connecting-rod bearings, piston pin bearings, rocker arm shaft bearings, bronze worm gears, and sintered brake and clutch discs. Resulting from the corrosion of oil coolers, piping, and seals. | |

Molybdenum | Mo | 4–20 Up to 500 in fresh oil | 15 | Contained in transmission synchroniser rings, piston rings, and heat-resistant steels. Component of an antioxidant and friction modifier additive package in modern synthetic multigrade oils and PD gear oils; rarely as MoS2 oil additives. | |

Nickel | Ni | 1 – 5 |

| Alloy constituent of exhaust valves, valve guides, turbochargers, high-strength gearwheels, and turbine blades. Instead of being galvanised or chrome plated, parts such as filter components may be nickel plated. Constituent of heavy oil (together with vanadium). | |

Vanadium | V | 1 – 3 |

| As chrome vanadium steel, an alloying component in valves and valve springs. Like nickel, it is a component of crude oil. Is blow-by product in the operation of ship engines with heavy oil fuels. | |

Tin | Sn | 12 – 24 | 5 – 10 | Often together with lead (Babbitt bearings) or copper. Running surfaces of connecting-rod bearings, rocker arm shaft and piston pin bearings, solder (consisting of lead and tin) in soldered radiator joints; constituent of some synthetic base oils, additives in flame-resistant fluids.

| |

Contaminants | |||||

| Antimony | Sb | 1 – 3 | 10 | Present in some lubricating greases as an EP additive in the form of antimony oxide; in connection with lead or tin in bearing alloys of plain bearings. | |

Beryllium | Be | 1 – 3 |

| CuBe valves and valve seats. Sintered bearings, constituents of sintered ceramic components or in jet engine oils. Prohibited in F-1 engines. | |

Cadmium | Cd | 1 – 3 |

| Components of plain bearings exposed to corrosion. Sometimes also deep red pigments in plastics and paints. | |

| Potassium | K | 2 - 30 | 5 - 10 | Additive in aqueous media such as glycol antifreeze or cooling water. Mineral salt in road salt or tap water. | |

| Cobalt | Co | 1 – 3 |

| Possibly from components of turbines or from roller bearing alloys in connection with iron. | |

Lithium | Li | 2 – 10 |

| Constituent of multipurpose greases (thickener). Indication of contamination by grease or assembly pastes. | |

| Manganese | Mn | 1 – 3 |

| Alloying element, usually with iron. Steel used in valves, roller bearings. gearwheels or shafts. Contaminant in manganese mines (with Si). Very rarely: additives containing manganese. | |

| Sodium | Na | 5–30 Up to 800 in fresh oil | 20 – 30 | Additive in glycol antifreeze or cooling water. Road salt, tap water or wastewater, salty air. Additive components in some motor oils as a substitute for calcium or magnesium compounds. Thickener in lubricating greases. | |

Silver | Ag | 1 – 3 |

| Silver-plated running surfaces of highly loaded plain bearings, such as in locomotive engines; silver solder residues. Silver is attacked by additive systems containing zinc. | |

Silicon | Si | 15–30 Up to 15 in fresh oil | 15 – 30 / | Dust in intake air, antifoam additive in motor oil, worn seals containing silicone, residues of parting agents and silicone greases (also in oil sampling syringes), worn aluminium alloys (all-aluminium engines). *For gas engines, organic compounds (silanes/siloxanes) from special gases. | |

| Titanium | Ti | 1 – 3 |

| Oil level indicator (float). Alloy constituent in springs and valves. From ceramic components. As white titanium oxide in plastics and paints. Marker additive in motor oils. | |

| Tungsten | W | 1 – 2 |

| 1 – 3 | Rare in engine construction; alloy constituent for increasing hardness and corrosion resistance. |

Cerium | Ce |

|

|

| Only found in oil as a constituent of ceramic components. |

| Tantalum | Ta | Only found in oil as a constituent of ceramic components. | |||

Zirconium | Zr |

|

|

| Only found in oil as a constituent of ceramic components.

|

Additive | |||||

Barium | Ba | 2-20 |

| 80 | Usually not an additive in motor oils. For improving EP characteristics. Friction modifier in ATFs. In the form of barium-complex soap, a constituent of greases and assembly pastes. |

Boron | B | 10 – 500 | 150 | Improves engine cleanness as an oil additive. Borates are constituents of cooler antifreeze and corrosion protection media. | |

| Calcium | Ca | 600 – 5000 | 500 – 3500 | Oil additive, detergent dispersant oil additive. Improves cleaning and dispersion capacity as well as heat resistance. Occasionally calcium-containing dust from building sites, lubricating grease constituent, or from cooling water or tap water containing calcium. | |

Magnesium | Mg | 100 – 1500 | 0 – 50 | Oil additive; improves the corrosion protection, thermal stability and dispersion capacity of motor oils. Increases the alkali reserve (BN). Alloy constituent of engine blocks. Hardening agent in hard tap water or salt water. | |

| Phosphorus | P | 600 – 2000 | 0 – 500 | Oil additive in almost all types of oil; used to improve EP characteristics and reduce wear; has an anti-corrosion and antibacterial effect, reduces friction, and renders metal surfaces chemically inert. | |

| Sulphur | S | 500 – 6000 | 500 – 9500 | Constituent of base oils based on mineral oil. For this reason it is present in almost all oils, but in widely varying amounts. Along with phosphorus, sulphur is also a constituent of almost all additive packages for wear and corrosion protection and is often found in connection with calcium and zinc. | |

| Zinc | Zn | Up to 2000 in fresh oil | 0 – 700 | Improves wear protection as an oil additive. Zinc-plated components such as filter support cores, threaded fittings, paints containing zinc, and vulcanised synthetic materials. | |

The informative value depends on the engine type, its oil filling quantity, the oil type and the time of use (mileage, operating hours) of the oil filling. Exceeding a single warning value does not necessarily mean that the oil must be changed.

Decisive for the informative value of the warning values is a comparative trend observation with previous samples from the same engine.

The following applies in principle to engine oils:

- Wear values should be set at a lower level: The larger the oil volume, the shorter the oil application time, the lower the engine RPM, the lower the load.

- Additives and their changes must always be critically examined with regard to mixing or additive degradation.

- Warning values for contaminants apply regardless of the operating time, oil volume and operating conditions.

Of the 29 elements in this table, we give 18 as standard in the laboratory report. The rest are only mentioned above 1 mg/kg. We also identify elements that are rare or difficult to determine. The limits listed are based on data from more than 500,000 used oil samples from engines of various types that we have analyzed.

However, the limit values or tolerance ranges published here only serve as a general guide under normal service lives and oil fill quantities for the respective case.

Diagnoses with the highest degree of accuracy can only be made by our engineers, who consider all values in interaction, taking into account the individual operating conditions.

![[Translate to "English"] Limitwerte für Motorenöle [Translate to "English"] Limitwerte für Motorenöle](/fileadmin/user_upload/img/wiki-pics/Automobilbereich_iStock-484151536.jpg)

Limit values for hydraulic oils

Wear | ||||

|---|---|---|---|---|

Element | Sign | Warning value | mostly in connection with | Possible causes |

Aluminum | Al | 25 | Si, Na, K, Cu | Die-cast parts, aluminium bronze, pump casings, guide mechanisms, plain bearings, oil coolers, multiple disc clutches, sealing rings |

| Antimony* | Sb | 3 | Zn, Pb, Cu | „Hardened lead" (lead antimony alloys) and tin alloys in plain bearings, white metal bearings |

Barium | Ba | 2 | - | Not a wear-induced metal in hydraulic oils |

Beryllium* | Be | 3 | Cu | Sintered metal bearings, Cu-Be alloys, ceramic components |

| Lead | Pb | 10 | Cu, Sn, W | Plain bearing running surface, pump casing, solder joints, rolling bearing cages |

Boron | B | 12 | Fe | Ceramic components, insulation bodies, brake and clutch linings |

Cadmium* | Cd | 3 | Ni | Corrosion-resistant Ni-Cd alloy |

Chrome | Cr | 25 | Fe, Cu, Al | Rolling bearings, vanes of vane pumps, chrome plated piston rods, pump raceway, other chrome plated components |

| Chlorine* | Cl | 20 | Fe,Cr | Abrasion of PVC plastic parts |

Iron | Fe | 50 | Cu, Cr, Mn | Hydraulic pump, hydraulic motor, valves, pistons, rolling bearings, tubing, casings, pipes, tank, cutting-ring fittings |

| Potassium | K | 15 | Al, Si, Na | Die-cast parts of light-metal alloys |

Calcium | Ca | 5 | V, Cl | rare alloy constituent, aggregate in PVC |

Cobalt* | Co | 2 | - | Not a wear-induced metal in hydraulic oils |

Copper | Cu | 25 | Fe, Pb, Al | Brass and bronze parts, control discs, pressure plates, pipes, oil coolers, rolling bearing cage, sealing and guide rings |

Lithium* | Li | 3 | Al, Mg, Fe | Light metal alloys in aviation hydraulics |

Magnesium | Mg | 5 | Al, Fe, V | Light-metal alloys for die-cast parts |

Manganese | Mn | 3 | Fe, Cu | Steel, high-grade steel, non-ferrous-metal alloys |

Molybdenum | Mo | 5 | Fe, Mn | Pump and valve parts made of high-strength alloys |

| Sodium | Na | 25 | Al, Si, K | Die-cast parts with light metal alloys |

Nickel | Ni | 3 | Fe, Mn | Nickel-plated supporting cores of filters, alloy constituent for valves, gearwheels |

Phosphorus | P | 10 | Fe, Cu | Abrasion of phosphated (hardened) surfaces, phosphorus bronze |

Sulphur | S | 30 | Fe | Rare alloy constituent, abrasion of rubber or plastic materials |

Silver* | Ag | 3 | Fe, Cu | Argentiferous solder joints |

| Silicon | Si | 10 | Al, Cu | Abrasion of light metal alloys, silicon seals |

| Titanium* | Ti | 3 | Fe | High-strength steels in special hydraulic systems, springs on check valves, level indicators, ceramic parts |

Vanadium* | V | 3 | Fe, Al | Chrome vanadium steel, titanium vanadium aluminium alloys |

| Tungsten* | W | 3 | Mo, Fe | Tool steel of W-Mo-Fe for high-strength parts |

Zinc | Zn | 70 | Fe, Cu, Al | Oil corrosion on zinc-coated components (zinc-free oils) |

Tin | Sn | 25 | Cu, Fe, Pb | Constituent of tin bronze, tin solder of cooler joints |

Elements marked with * appear in standard laboratory reports for hydraulic oils only for values over 1 mg/kg (1ppm)

Additive | ||||

|---|---|---|---|---|

Element | Sign | typical range | mostly in connection with | Possible causes |

Aluminum | Al | < 2 | - | no significance for hydraulic oilse |

| Antimony* | Sb | < 2 | - | no significance for hydraulic oilse |

Barium | Ba | 50 - 8000 | S, P | Type A ATF (automatic transmission fluid) friction modifier |

Beryllium* | Be | < 2 | - | no significance for hydraulic oils |

| Lead | Pb | < 30 | S, P | Friction-reducing friction modifier (no longer in common use, in the past a wear inhibitor in lubricating greases and transmission oils) |

| Boron | B | < 40 | - | Cleaning supplement, friction modifier in engine and gear oils |

Cadmium* | Cd | < 2 | - | no significance for hydraulic oils |

Chrome | Cr | < 2 | - | no significance for hydraulic oils |

| Chlorine* | Cl | < 2 | - | no significance for hydraulic oils |

Iron | Fe | < 2 | - | no significance for hydraulic oils |

| Potassium | K | < 2 | - | no significance for hydraulic oils |

| Calcium | Ca | < 3000 | P, Zn, S | Detergent in HLPD hydraulics and engine oils, thermal resistance, wear inhibitor, also in lubricating greases |

| Cobalt* | Co | < 2 | - | no significance for hydraulic oils |

| Copper | Cu | < 2 | - | no significance for hydraulic oils |

Lithium* | Li | < 2 | - | no significance for hydraulic oils |

Magnesium | Mg | < 1500 | Ca, P, Zn, S | Detergent in HLPD hydraulic and engine oils, thermal resistance |

| Manganese | Mn | < 2 | - | no significance for hydraulic oils |

| Molybdenum | Mo | < 250 | - | Molybdenum-organic additives for the use of gear and engine oils |

| Sodium | Na | < 300 | Ca, Mg, P, Zn, S | rare additive for the use of engine oils |

Nickel | Ni | < 2 | - | no longer significant for hydraulic oils |

| Phosphorus | P | < 2000 | Zn, S | Attrition and corrosion reduction additive (high-pressure supplement) in almost all oils |

Sulphur | S | < 10.000 | P, Zn | Wear-inhibiting additive in almost all oils, constituent of mineral base oils |

Silver* | Ag | < 2 | - | no significance for hydraulic oils |

Silicon | Si | < 15 | Ca, P, Zn, Mg | Anti-foam additive from oils |

Titanium* | Ti | < 2 | - | no significance for hydraulic oils, rarely as a marking supplement |

Vanadium* | V | < 2 | - | no significance for hydraulic oils |

| Tungsten* | W | < 2 | - | no significance for hydraulic oils |

Zinc | Zn | < 1500 | P, S | Wear-inhibiting high-pressure additive, reduces friction (friction modifier), ageing resistance |

Tin | Sn | < 300 | P | In some synthetic oils, depending on manufacturing process |

Elements marked with * appear in standard laboratory reports for hydraulic oils only for values over 1 mg/kg (1ppm)

Contaminant | ||||

|---|---|---|---|---|

Element | Sign | Warning value | mostly in connection with | Possible causes |

Aluminum | Al | 10 | Si, Ca | Dust from clay or loam floor, bauxite dust, bentonite, gel or aluminium complex grease |

| Antimony* | Sb | 7 | Pb | Soft-solder constituent, pigments from coats of paint, antioxidant in lubricating grease |

Barium | Ba | 19 | P, S, Zn | Mixing with Type A ATF, lubricating grease, assembly paste, corrosion inhibitor, hardening baths |

Beryllium* | Be | 2 | - | None known for hydraulic oils |

| Lead | Pb | 8 | Cu, Sn, W | Soldered connections |

Boron | B | 20 | Na, K | Cooling-grease and cooling-fluid supplement, fluxing agent for solder joints, detergent supplement, pesticide |

Cadmium* | Cd | 3 | Cu, Sn, V | Dye pigments, disc brake lubricant, tin-lead solder in hard solders |

Chrome | Cr | 2 | - | None known for hydraulic oils |

Chlorine* | Cl | 20 | Fe, Na, K | Seawater, table salt, swimming-pool water supplement, chlorine gas, PCB, chlorinated refrigerants, supplement in some cutting fluids |

Iron | Fe | 10 | - | Additive in lubricant grease and assembly pastes |

Potassium | K | 15 | Na | Gritting salt, artificial fertiliser or tap water, seawater, saline air, cooling water (glycol), cutting fluid |

Calcium | Ca | 15 | Na, K, Si | Made of hard cooling fluid, engine oil, rock dust (e.g. dolomites) |

Cobalt* | Co | 2 | - | None known for hydraulic oils |

| Copper | Cu | 5 | Fe, Pb, Al | Corrosion products, chisel paste |

Lithium* | Li | 3 | Ca, Zn, P | Thickener of multipurpose grease, assembly paste |

Magnesium | Mg | 9 | Ca, Zn, P | Mixing with engine oil, tap or waste water |

| Manganese | Mn | 2 | - | None known for hydraulic oils |

| Molybdenum | Mo | 20 | Ca, Zn, P | Mixing with engine oils or PD gear oils, MoS₂ in assembly pastes and greases |

| Sodium | Na | 19 | Al, Si, K | Gritting salt, artificial fertiliser or tap water, seawater, saline air, thickener of lubricating greases, corrosion inhibitor made out of oil or antifreeze glycol (non-ferrous metal protection) |

Nickel | Ni | 2 | - | Nickeliferous assembly paste |

Phosphorus | P | 10 | Si, Ca, Al | Dust, artificial fertiliser |

Sulphur | S | + 1.000 | P | Mixing with hypoid gear oils |

Silver* | Ag | 3 | Zn | Residue of silver solder because of corrosion by oils containing zinc |

Silicon | Si | 10 | Al | Dust or arenaceous quartz; glass dust; silicon oil, grease or spray; plastic release agent; silicon sealing or caulking compounds |

Titanium* | Ti | 3 | S | Titanium oxide in plastics, paper and printing colours |

Vanadium* | V | 2 | - | None known for hydraulic oils |

Tungsten* | W | 2 | Fe | Residue from welding electrodes |

Zinc | Zn | 50 | Fe, Cu, Al | Dye pigments, vulcanisation aids in tubing, mixing with oils containing zinc |

Tin | Sn | 2 | - | None known for hydraulic oils |

Elements marked with * appear in standard laboratory reports for hydraulic oils only for values over 1 mg/kg (1ppm)

Notes on use: Information about the origin, amount and combination of elements in this table is based on typical used oil samples from mobile and stationary hydraulic systems. These metals were measured in more than 1 million hydraulic oil samples by means of ICP in the OELCHECK laboratory. Out of approximately 40 elements recorded by us in every sample, we often only mention those of the 29 elements listed here that show a value higher than 1. OELCHECK is the only laboratory that uses calibrating standards for more than the 18 standard elements. Even rather rare or hard-to-determine elements like lithium, chlorine or manganese are calibrated within the range typically found in oils. Because no commercially available standards exist, the presence of some metals can only be exactly determined up to a concentration of 5000 mg/kg.

Please note, especially for wear-induced metals and some contaminants: The typical warning values, especially for wear metals and some impurities, depend on the oil‘s current service life and the size of the oil charge. In addition, the trend curve, which can be ascertained through regular analyses of the same aggregate, is also important. Perform one or two analyses per year and supply data that is as complete as possible if you value getting a sound diagnosis by an experienced OELCHECK tribologist.

![[Translate to "English"] Limitwerte für Hydrauliköle [Translate to "English"] Limitwerte für Hydrauliköle](/fileadmin/user_upload/img/wiki-pics/Forst-iStock-494896243-72.jpg)

Limit values for gear and industrial oils

Wear | |||||

|---|---|---|---|---|---|

Element | Sign | Warning value mobile/stationary | mostly in | Possible causes | |

Aluminum | Al | 45 | 20 | Si, Cu, Mg | Worm wheels (aluminum-bronze), clutches, oil pumps, pressure or aluminum cast parts, housings, aluminum sealing rings |

Antimony* | Sb | < 7 | < 3 | Sn, Pb, Cu | Hard lead, zinc alloys on bearings, white metal bearings, solder (soft solder) |

Barium | Ba | 2 | 2 | - | No typical wear element in gears |

Beryllium* | Be | 3 | 3 | Al, Cu | Lightweight construction parts made from sintered metal, beryllium-copper alloy |

Lead | Pb | 20 | 10 | Cu, Zn, Sb | Plain bearing running surface, lead bronze, synchroniser rings, coats of paint |

Boron | B | 12 | 12 | Fe | Ceramic components, insulation bodies, brake and clutch linings |

Cadmium* | Cd | 2 | 2 | - | No typical wear element in gears |

Chrome | Cr | 20 | 10 | Fe, Ni, Mn, Mo | Roller bearings, alloy constituents of high-strength gearwheels |

Chlorine* | Cl | 2 | 2 | - | No typical wear element in gears |

Iron | Fe | 490 | 150 | Cu, Ni, Cr, Mn, Mo | Gearwheels, rolling bearings, oil pumps, steel lamina couplings, cast housings, shafts, radial serrations, planetary carriers |

| Potassium | K | 2 | 2 | - | No typical wear element in gears |

| Calcium | Ca | 2 | 2 | - | No typical wear element in gears |

Cobalt* | Co | 2 | 2 | - | No typical wear element in gears |

| Copper | Cu | 75 | 40 | Zn, Sn, Pb, Sb | Bronze worm wheels, friction bearings, roller bearing cages, oil coolers, synchroniser rings, brass |

Lithium* | Li | 2 | 2 | - | No typical wear element in gears |

Magnesium | Mg | 9 | 4 | Al | Aluminum die-cast alloy |

| Manganese | Mn | 20 | 20 | Fe, Cr, Ni, Cu | Roller bearings, pumps, general high-alloyed steels |

| Molybdenum | Mo | 14 | 8 | Fe, Cr, Ni | Constituent of high-strength alloys e.g. for hardened gearwheels or roller bearing steel |

| Sodium | Na | 2 | 2 | - | No typical wear element in gears |

Nickel | Ni | 17 | 5 | - | Constituents of high-strength alloys e.g. for hardened gear wheels or roller bearing steel, nickel-plated components |

Phosphorus | P | 2 | 2 | - | Phosphated (hardened) surfaces, generally covering with P as additive |

| Sulphur | S | 2 | 2 | - | No typical wear element in gears |

Silver* | Ag | 4 | 4 | - | Plain bearing, silver solder |

| Silicon | Si | 23 | 9 | Al | Aluminum die-cast parts, e.g. housings |

Titanium* | Ti | 3 | 3 | Fe | Alloy constituent of high-strength steels |

Vanadium* | V | 2 | 2 | - | No typical wear element in gears |

Tungsten* | W | 2 | 2 | - | No typical wear element in gears |

Zinc | Zn | 41 | 78 | Cu | Roller bearing cages, coolers, zinc-coated components (e.g. fi lter support cores), brass components |

Tin | Sn | 20 | 20 | - | Plain bearing |

The „mobile“ warning values apply to vehicle gears and to oil fi llings from mobile systems. The „stationary“ warning values refer to oils from gears in stationary industrial systems. Values above or below the warning values do not always mean that the oil should be changed.

Elements marked with * appear in the standard lab report for gear oils only for values above 1 mg/kg (1 ppm.)

Additive | ||||

|---|---|---|---|---|

Element | Sign | typical | mostly in connection with | Possible causes |

Aluminum | Al | < 50 | Si | Aluminum silicate-based nanoparticle additive |

Antimony* | Sb | 2 | - | No typical additive components for gear oil |

Barium | Ba | < 2000 | P, Zn | Friction-reducing additive (friction modifier) in automatic gear oils, unusual for industrial gear oils |

| Beryllium* | Be | 2 | - | No typical additive components for gear oil |

| Lead | Pb | < 3 | - | Reduces friction (friction modifier) (previously used as a wear protector, no longer commonplace today) |

| Boron | B | < 400 | - | Friction-reducing additive (friction modifier) |

Cadmium* | Cd | 2 | - | No typical additive components for gear oil |

| Chrome | Cr | 2 | - | No typical additive components for gear oil |

| Chlorine* | Cl | < 30 | - | Chlorinated additives to protect against wear are only rarely used today as cooling lubricants |

| Iron | Fe | 2 | - | No typical additive components for gear oil |

| Potassium | K | 2 | - | No typical additive components for gear oil |

| Calcium | Ca | < 4000 | P, S | Detergent (cleaning) and dispersent (for keeping in suspension) additives, UTTO, engine oils |

| Cobalt* | Co | 2 | - | No typical additive components for gear oil |

| Copper | Cu | 2 | - | No typical additive components for gear oil |

Lithium* | Li | 2 | - | No typical additive components for gear oil |

Magnesium | Mg | < 2000 | - | Detergent (cleaning) and dispersent (for keeping in suspension) additives, UTTO, engine oils |

| Manganese | Mn | < 2 | - | No typical additive components for gear oil |

Molybdenum | Mo | < 2000 | P, S, Ca, Mg | Molybdenum-organic additives, for gear oils with PD effect, MoS2 |

| Sodium | Na | < 200 | - | Non-ferrous metal protection, corrosion protection |

Nickel | Ni | < 2 | - | No typical additive components for gear oil |

| Phosphorus | P | < 2000 | S | Wear and corrosion protection additive, extreme pressure additive |

| Sulphur | S | bis 3% | P | Additives to protect against wear, in hypoid gear oils, constituent of mineral base oils |

Silver* | Ag | 2 | - | No typical additive components for gear oil |

| Silicon | Si | < 40 | - | Anti-foaming additives, nanoparticles in combination with Al |

| Titanium* | Ti | 2 | - | No typical additive components for gear oil |

Vanadium* | V | 2 | - | No typical additive components for gear oil |

| Tungsten* | W | 2 | - | No typical additive components for gear oil |

| Zinc | Zn | < 1500 | - | Wear-reducing extreme pressure additive, reduces friction (friction modifier), resistance to ageing |

Tin | Sn | < 2 | - | No typical additive components for gear oil |

The „mobile“ warning values apply to vehicle gears and to oil fi llings from mobile systems. The „stationary“ warning values refer to oils from gears in stationary industrial systems. Values above or below the warning values do not always mean that the oil should be changed.

Elements marked with * appear in the standard lab report for gear oils only for values above 1 mg/kg (1 ppm.)

Contaminant | ||||

|---|---|---|---|---|

Element | Sign | Warning value | mostly in connection with | Possible causes |

Aluminum | Al | < 20 | Si | Dust from mines, e.g. bauxite |

| Antimony* | Sb | < 10 | Li, Ca | Contamination due to lubricating grease |

Barium | Ba | < 15 | - | Contaminant due to greases and pastes containing barium, blending with an ATF |

Beryllium* | Be | 2 | - | Unusual as a contaminant |

| Lead | Pb | < 3 | - | Blending with leaded grease, leaded paint coats |

Boron | B | < 10 | Na, K | Cooling-grease and cooling-fluid supplement, fluxing agent for solder joints, detergent supplement, pesticide |

Cadmium* | Cd | 3 | Cu, Sn, V | Dye pigments, disc brake lubricant (cadmium poses a danger to health and has been banned in many applications in the EU since 2011) |

Chrome | Cr | 2 | - | Unusual as a contaminant |

Chlorine* | Cl | < 30 | Fe, Na, K | Seawater, table salt, chlorine gas, PCB, chlorinated refrigerants, supplement in some cutting fluids |

Iron | Fe | 2 | - | Additive made from lubricant grease or assembly paste |

| Potassium | K | - | Na | Gritting salt, synthetic fertiliser, from tap water, sea salt, salty air, coolant (glycol), metal working oil |

| Calcium | Ca | < 15 | Na, K, Si | From hard (cooling) water, engine oils, mineral dust (e.g. dolomite), from hydraulic oils, calcium saponified greases |

| Cobalt* | Co | 2 | - | Unusual as a contaminant |

Copper | Cu | 11 | Fe, Pb, Al | Abrasion of friction lining of multiple disc clutch or brakes, from plumping pipes, sealing rings, synchronising sealing rings, high temperature paste |

Lithium* | Li | 20 | Ca, Zn, P | Thickener of multipurpose grease, assembly paste |

Magnesium | Mg | < 15 | Ca, Zn, P | Blending with engine oil, tap or waste water, also possible from hydraulic oils, or alloy component constituents |

Manganese | Mn | 2 | - | Unusual as a contaminant |

| Molybdenum | Mo | < 15 | Ca, Zn, P | Assembly paste, grease, blending with engine oil |

| Sodium | Na | < 24 | Al, Si, K | Gritting salt, synthetic fertiliser or tap water, sea salt, salty air, grease thickener, antifreeze (glycol) |

Nickel | Ni | < 6 | - | Assembly paste containing nickel |

| Phosphorus | P | < 20 | Si, Ca, Al | Dust, synthetic fertiliser |

| Sulphur | S | 2 | - | Unusual as a contaminant |

Silver* | Ag | 2 | - | Unusual as a contaminant |

| Silicon | Si | 19 | Al | Dust or arenaceous quartz, glass dust, silicon oil, silicon grease or silicon spray, plastic release agent, silicon sealing compounds |

| Titanium* | Ti | < 40 | - | Used as a marker to prove the authenticity of the oil by the manufacturer |

Vanadium* | V | < 10 | Nl, Al, Bi | Constituent in heavy oil, dye and occasionally in greases |

| Tungsten* | W | < 4 | Fe | Residue from welding electrodes, TIG welding |

Zinc | Zn | < 80 | Fe, Cu, Al | Coats of paint containing zinc, abrasion of sealing compounds, blending with oils containing zinc |

Tin | Sn | < 9 | - | Soldering joints, coatings, as a constituent of ester oils |

The „mobile“ warning values apply to vehicle gears and to oil fi llings from mobile systems. The „stationary“ warning values refer to oils from gears in stationary industrial systems. Values above or below the warning values do not always mean that the oil should be changed.

Elements marked with * appear in the standard lab report for gear oils only for values above 1 mg/kg (1 ppm.)

Interpretation of values above

The experienced tribologist assesses all values in interaction and also takes into account the individual operating conditions. The limit values or tolerance ranges published here can therefore only serve as a general guide for an application with a service life and oil fill quantity that are usual for this application.

Limit values for wear metals should be set all the lower:

- the larger the oil quantity

- the shorter the operating time

- for motors: the lower the RPM

- for hydraulics: the higher the operating pressure

- for gearboxes: the higher the peripheral speed

Additives and their changes should always be critically scrutinized, especially if they may indicate mixing with the wrong oil. If zinc is detected in a used oil that does not in itself contain zinc as an additive, its origin must be determined in any case.

Contaminants, their warning values apply regardless of the operating time, oil quantity and loads. Too much dust is always too much!

Our tip: With one to two lubricant analyses per aggregate per year, you not only receive well-founded diagnoses from an experienced OELCHECK tribologist - but they also make trend developments visible. This not only provides you with a valuable tool for the early detection of wear.

![[Translate to "English"] Limitwerte für Getriebe- und Industrieöle [Translate to "English"] Limitwerte für Getriebe- und Industrieöle](/fileadmin/user_upload/img/wiki-pics/Image_0100Zahnrad16.jpg)

ÖlChecker Spring 2010, page 6/7

ÖlChecker Summer 2011, page 6

OELCHECKER Winter 2014, page 5 - 6

OELCHECKER Spring 2015, page 4 - 5