REM-EDX

REM-EDX, this abbreviation says a lot! It stands for a new test method, the "raster electron microscopic analysis by means of energy-dispersive micro range analysis". The process precisely determines the elemental composition of particles. Based on the results of the determined metal alloys, inferences can be made with regard to certain components from which particles with a size of only a few micrometres originate.

Thus, the REM-EDX analysis provides the perfect support when searching for machine elements with signs of wear or determining contaminations in the form of solids. The analyses are performed by Industrieanlagen-Betriebsgesellschaft mbH (IABG) in Ottobrunn near Munich. OELCHECK’s cooperation partner has the necessary high-tech equipment and well-founded expertise for examining and assessing complex damage incidents. OELCHECK separates the particles that are to be analysed from the oil samples, provides background information and assists with the diagnosis of analysis results. Metallic abrasion quickly intrudes into oil or grease if wear or contamination particles attack lubricated machine components. OELCHECK already detects even the smallest particles in oil samples in the initial stages of the wear process. Atomic emission spectroscopy (AES) detects up to 30 elements that make up the particles. However, this analysis reaches its limits when dealing with particles that are larger than 5 μm. The exact composition and origin of larger particles or hard residue found in filters, oil samples or waste oil can often be clarified with an REM-EDX analysis.

Table of contents

Which particles are examined?

The analysis is suitable for the analysis of all inorganic, solid particles that are filtered from oils, grease or operating fluids, possibly after being treated with a solvent.

How are the samples prepared?

The customer can send a sample with visible particles or particles that he has already separated himself to the OELCHECK laboratory. A clear issue statement and possible comprehensive information regarding lubricated components, the lubricant and other anomalies is very important. In the laboratory, OELCHECK filters the conspicuous particles from the lubricant or processes them directly. The soap structure of lubricating grease must first be destroyed with solvents prior to filtering. The particles are restructured from the filter membrane and transferred to a carbon pad with a diameter of 2.5 cm. OELCHECK then sends this pad together with the exact issue statement and information about the lubricant and relevant system to the cooperation partner.

How is the analysis performed?

Up to five representative or conspicuous particles are transferred to a membrane and observed in vacuo in the IABG laboratory. The raster electron microscope is connected to an energy-dispersive micro range analysis EDX (energy dispersive X-ray spectroscopy). The elements that constitute the particles are determined. An electron beam moves over the particles in a raster pattern during the analysis. An image is generated from the interactions between the electrons and the particles. The surfaces of the particles are enlarged by up to 500,000:1, which corresponds to the lateral resolution of 0.6 mm. In combination with the energy-dispersive micro range analysis EDX, the electron beam of the REM also plays an important role. If an electron from the electron beam strikes a negatively charged electron in the atom of the particle that is near the nucleus and moves it from its position, then this space is immediately filled by an energy-rich electron from a higher orbital. The energy difference of both electrons is freed in the form of an X-ray quantum. The resulting X-radiation is characteristic for a specific element. Elements from the atomic number 6 (excluding carbon) and from a mass fraction of 0.3 m% can be verified. Thus, the chemical composition is determined for each examined particle. Which information does the customer receive? A laboratory report is prepared after the analysis.

- The report contains a precise description of the task.

- A photo documents the as-delivered condition of the particles on the carbon pad.

- The result of the analysis comprises a list of the main and trace elements of each particle. Possible compounds or alloys are stated that may constitute the original material. Galvanised steel is very likely the material in question if a particle mainly contains iron and additionally zinc, manganese and nickel as trace elements. Additionally, a semi-quantitative analysis is performed for one or multiple particles that are especially conspicuous due to their composition. A table lists the mass fractions of the elements in %.

- The customer receives a diagnostic and assessment statement such as: “The particle can be assigned to a low-alloyed steel such as quenched and tempered steel.”

- The annex includes additional pages that illustrate the analysis results with magnified illustrations and diagrams.

Insights into the world of particles

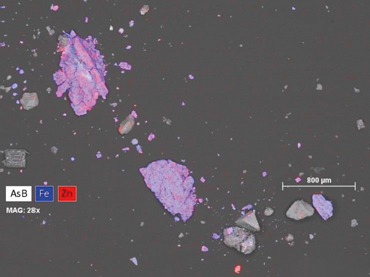

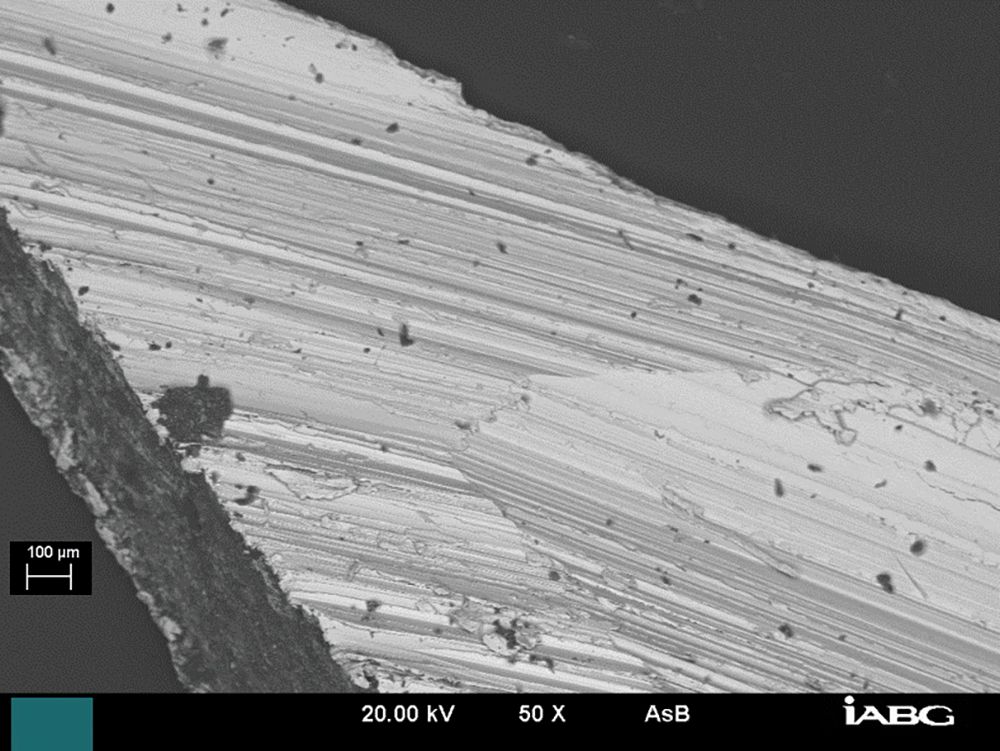

The figures elucidate what is possible with the REM-EDX test method. The particle consists to 98.5% of iron and contains traces of manganese, aluminium and silicon. It can be assigned to a low-alloyed, manganese-containing steel with a slightly contaminated surface. The large particle at the top left is zinc-coated steel. In the image, the element distribution is displayed with colours. The particle contains 61.5% iron and 14.1% zinc with traces of manganese, nickel and silicone.

Cooperation partner IABG

IABG offers integrated, innovative solutions for the sectors automotive – information communications – mobility, energy & environment – aerospace – defence & security. We provide independent and competent consultation and realise projects in a future-proof and targeted manner. We operate reliably and sustainably. Our success is based on understanding market trends and requirements, our employees’ technological competence and a fair relationship with our customers and business partners.

OELCHECKER Summer 2019, page 3