How do I take an oil sample correctly?

A frequently asked question in the OELCHECK customer hotline is: How do I take an oil sample correctly?

Six basic rules for optimal sampling

- during operation or shortly after standstill — because dirt and wear particles are still in suspension, any water that may be present has not yet settled

- at normal operating temperature – warm oil can be removed more quickly

- always according to the same method and in the same place

- if possible in front of the filter, never out of the filter

- not shortly after an oil change or after larger quantities of oil have been refilled

- only into a clean and dry bottle – preferably immediately into an original OELCHECK sample bottle

The analysis of an oil sample is used to check the condition of the entire lubricant quantity out of which it was taken. In addition, the values determined should allow conclusions to be drawn about the unit itself. The sample taken is thus representative of the lubricant used.

Oil sampling must therefore be representative, timely and properly documented. Only in this way, the laboratory can draw the correct conclusions from the values determined. However, errors can occur during sample collection that have a direct impact on the test results. To eliminate such risks, the following basic rules for proper sample collection should be followed.

Sampling during operation or shortly after a standstill is ideal. Dirt and wear particles are then still in suspension. Any water present has not yet settled. The oil is still at about operating temperature. It therefore has a lower viscosity and is easier flowable than in the cold state.

The oil should always be taken from the same place. It must also be easily accessible for future sampling. An oil sample drawn directly from the oil sump, oil filter, or at the deepest point may contain too much sludge, settled water, or abrasion. A sample skimmed from the oil surface may have a water-air mixture added.

If a sample is taken shortly after the filter, there are hardly any wear metals and impurities left in it. Important information is lost this way.

For serial analyses, sampling must always be performed using the same method. In some cases, the drain plug offers the only possibility for sampling. This procedure does not require any tools, but it does require skill. First, half a liter of oil is drained off as flushing oil. Only then is the sample bottle held in the oil stream. Under no circumstances should the sample bottle be used to scoop out the drained oil or the filter housing be emptied into the sample bottle.

Better suited, but more complex to install, is the extraction of the oil sample via a special extraction valve. In the case of hydraulics, a minimess connection takes over this function. If possible, the sampling point should be installed in the return line upstream of the filter. If this installation is not possible, the valve can alternatively be installed halfway up the oil level in the oil tank. The valve itself should be equipped with a dust cap. Before removal, clean it with a clean, lint-free cloth so that no dirt gets into the sample bottle. Before the actual sampling is performed, the valve should be flushed with a small amount of oil.

The sample pump – a practical aide

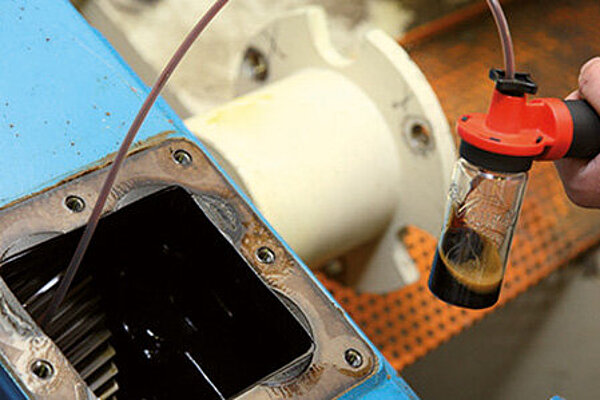

Simple and trouble-free sampling is performed with a special sample pump. It is used especially when there is no oil change at the time of sampling, or when the oil sample is to be drawn through a dipstick opening.

The OELCHECK sample pump consists of the pump, interchangeable sampling hose and a knife, ballpoint pen, wipes and instructions for use. The OELCHECK sample bottles are screwed directly onto the pump. The hose can be plugged on without any problems. The pump works on the vacuum principle, as simple as an air pump.

All oils up to a viscosity of ISO 680 or SAE 60 or 140, but also other liquids, are conveyed cleanly and without problems directly into the sample vessel. The pump itself does not come into contact with the oil.

The sample bottles – dry, clean and stable

Old paint cans, coke bottles or even coffee cups are absolutely unsuitable for sampling.

Special care should be taken with some synthetic oils that attack or soften plastic. The plasticizers diffused into the oil can even change the composition of the lubricant.

Regardless of the method used to collect the sample, the oil should always be poured directly into an OELCHECK sample bottle. It is suited for lubricants, synthetic liquids and for fuels. Each OELCHECK sample bottle is specially tested for purity so that particle counts can also be carried out without any problems. It also closes cleanly, and its lid seal is made of lint-free plastic foam rather than cork flour.

The price of an OELCHECK sample bottle already includes a corresponding lubricant analysis. You should always keep OELCHECK analysis kits in stock. Therefore, in a worst-case scenario, you don't have to resort to using a rinsed-out Coke bottle again.