Coolant analyses uncover damage in cooling systems

It's not just oil that can talk. Coolant can too. And at OELCHECK, we understand its message. Coolant analysis has only recently been 'booming', as machinery manufacturers and operators have increasingly recognised the potential that they can tap into through regular coolant analyses. Just like lubricants, the mostly water-based coolants' properties also change through ageing and pollution. Ready-mixed coolants or water to which special concentrates have been added have a range of duties: they ensure optimum heat supply and extraction, protect against corrosion, cavitation and deposits and prevent freezing at sub-zero temperatures. They are used for cooling engines in vehicles, construction machinery, locomotives and petrol engines, but also for cooling electric drives in wind turbines or new e-vehicle drives. In order to ensure operability over a long period of time and therefore the safe operation of the cooled units, OELCHECK investigates all important parameters.

Table of contents

And success proves us right!

We now analyse over 500 coolant samples each month and have built a lab team specialising in the analysis of water-based coolant fluids due to the rising demand. As well as a variety of devices for water analysis, another ion chromatography (IC) has been put into operation alongside the existing one. The 5,000 coolants and counting analysed so far show that OELCHECK has had a good nose for new coolant analyses from the outset. The number of people who took part in our partner OilDoc's coolant symposium, which took place on 14 and 15 March 2018 in Brannenburg, also indicates the growing interest. As well as fascinating presentations by manufacturers and consumers, Dr Thomas Fischer, Scientific Director at OELCHECK, presented various coolant analysis procedures. And our coolant expert Matthias Aßmann then explained how he, as a mechanical engineer, produces a diagnosis regarding the state of the coolant and any problems in the cooling system based on the analysed values. During a tour through the OELCHECK laboratory focusing on the main points of coolant analysis, the participants gained many interesting insights and additional knowledge and food for thought.

Coolant analysis

OELCHECK's coolant analyses cover the following areas:

- Coolant state, ageing

During ageing and oxidation, decomposition products with acidic properties are produced in the coolant, which can be detected in the form of acetate, formate, glycolate and oxalate. - Water quality

In terms of water quality, the focus is mostly on water hardness and the level of chlorine- and sulphur-containing compounds or a generally unsuitable water. - Decomposition products, additive modifications

Additives that help the coolant perform its various duties decompose over time. Additive concentration therefore allows conclusions to be drawn on the coolant's suitability for use going forward. - Contaminants

Contaminants may be detected in the form of dust, for example, a combination of coolants or metal elements which are disseminated from the components built into the system and thereby provide indications on improved upkeep.

The analysis kits

Just like for lubricant analyses, OELCHECK offers a variety of prepaid coolant kits with a predefined scope of analysis. But what conclusions can be drawn from it? Quality control and a comparison of fresh products is usually done on the basis of a 'premium analysis'. With the 'advanced' kit, coolant ageing or a mixture with another type of coolant can be detected. However, the same kit can also be used to draw conclusions on unsuitable base water or metallic contaminants. A conclusion can be drawn on whether corrosion processes have already begun in the cooling system using the analysis kit 2, 'basic', in the form of an element analysis. If the reason for changes must be unambiguously clarified, then OELCHECK recommends carrying out an ion chromatography.

The diagnosis – Lab values enhanced by information on damage

The interpretation and diagnosis of analysis results is often not clear, unlike the measurement of individual values. It is therefore absolutely crucial for the experienced tribologist who produces the diagnosis that they also receive basic information, such as on the place and time of use, in the form of a completed sample information form, alongside the many lab values. Without this basic knowledge, in many cases, it is not possible for the OELCHECK tribologist who interprets the lab values for the end consumer, despite their experience and a comparison with the values saved in our database from many coolant analyses, to give a helpful recommendation on action to be taken. A coolant analysis can, just like an oil analysis, point to advanced ageing (glycol decomposition products) or cavitation and corrosion damage (aluminium from aluminium components). Two typical examples from the field of coolant analysis make this clear.

Example 1: Analysis of base or heating water

A special feature in the field of coolant analysis is the analysis of as yet unmixed, unadditivised base water or heating water.

The evaluation of analysis values mostly takes place based on the specifications of the manufacturer of engines or coolant concentrates.

For water intended for use in heating (not cooling), further guidelines (e.g. VDI 2035) may be used as a basis. In the analysis of base water, the chloride and sulphate content is very important, as well as the pH value and water hardness, as chlorides and sulphates can favour corrosion and reduce the efficacy of corrosion inhibitors.

Example 2: Contamination due to fluxes

Flux is mostly used in the form of soldering fluid when soldering coolers and pipes in order to achieve improved wetting of surfaces through the solder. They remove oxide layers and reduce the surface tension by means of a chemical reaction. This achieves an improved soldering result. The mostly acidic fluxes react aggressively and can cause corrosion at the soldering point if they are not removed. A concentration of flux residue that is too high is now either uncovered by sampling the cooling water, or it can become apparent through leakages in industrial cooling circuits. Some flux components hardly dissolve in water. As a result, only traces of these can be found in coolant samples. Whether they are at all present in cooling water is shown by the analysis values in the form of a reduced pH value and an increased level of glycol decomposition products. Increased potassium values and decomposed anti-corrosive additives are also notable. The latter is then also visible through metal components which indicate increased corrosive wear. Due to the poor solubility of fluxes in cooling water, any such contamination cannot be eliminated, even with several coolant changes. Expensive corrosion damage can then only be avoided here with the help of regular analyses.

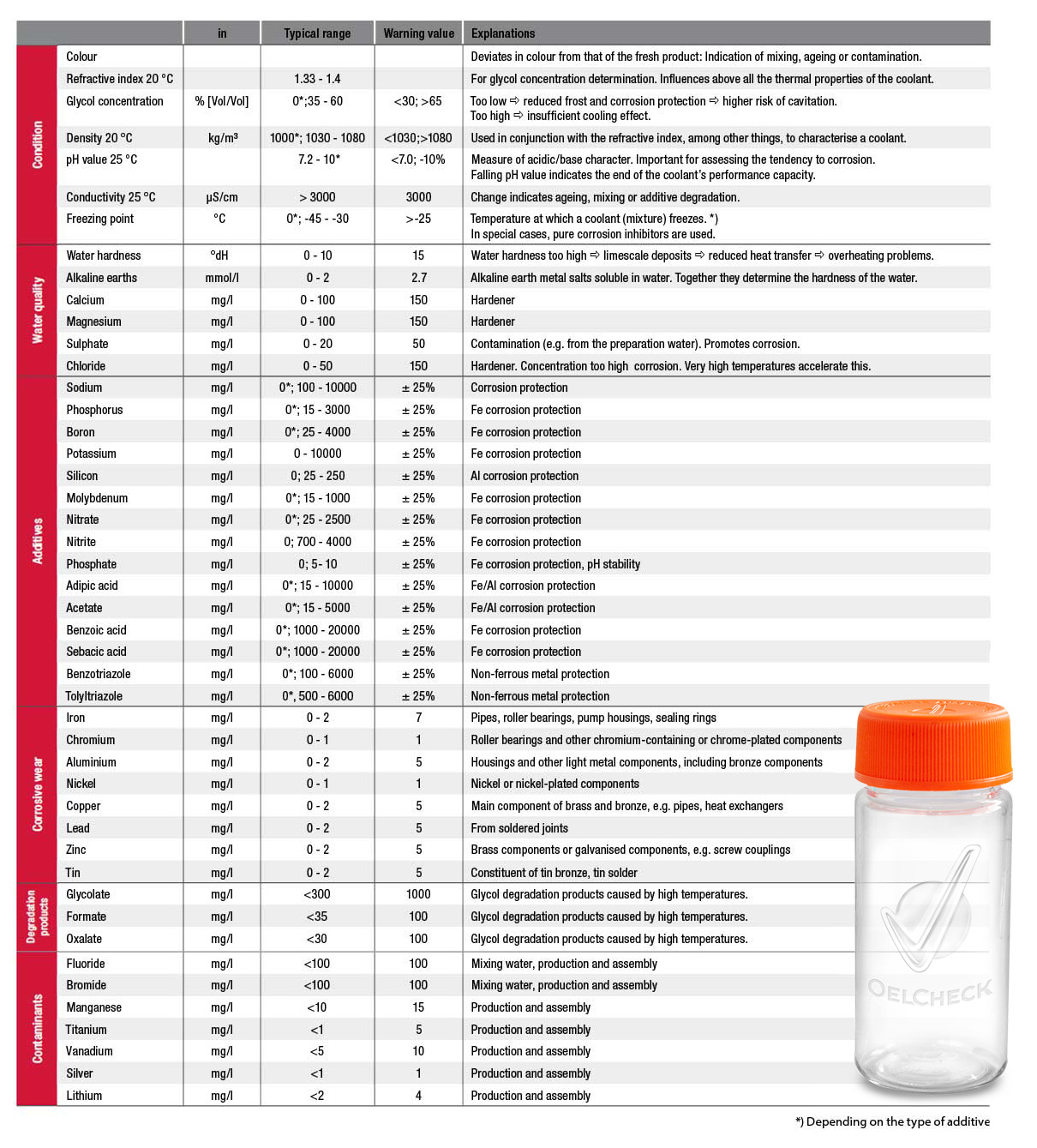

Coolant analysis - Typical limits

As in the assessment of lubricant analyses, the OELCHECK tribologists always consider the values determined for coolants in their interplay. They also take into account the individual application conditions and the results of previous trend analyses.

The limit values or tolerance ranges published here are for general guidance only. They are based on the specifications of well-known engine manufacturers and on the data of all coolant samples that OELCHECK has examined since 2017.