Disposal and selection of rapidly biodegradable hydraulic oils

Year of publication: 2009, revised 2023

More than 20% of lubricants are not recycled. They leak into the ground or the water and disappear, they form films on components, or they remain in decommissioned machinery. In some cases, incorrect disposal results from inadequate information. In this regard, the impression suggested by the term “bio-oil”, supported by the “Blue Angel” or the European daisy symbol, is enormously deceptive. Even oils with this designation should not end up in the environment. Users often think that as long as they use rapidly biodegradable hydraulic fl uids, they do not have to take any action if a fairly large volume of hydraulic fluid ends up in the environment (soil or water). Using these synthetic fluids does not free users from the obligation to inform the authorities of environmental spills and to remove the fluid from bodies of water or polluted soil. Furthermore, simply allowing hydraulic fluid to drain into the ground when the fluid is changed is entirely out of the question, even with “bio-oils”.

Lubricant disposal is regulated by law, such as the Altölgesetz (Waste Oil Act) in Germany. Bio-oils are not exempted. They are treated in the same way as corresponding synthetic oils or mineral oils. Rapidly biodegradable, environmentally compatible oils should be used by preference for work in environmentally sensitive areas.

The storage of working materials is regulated by classifying them according to their water hazard. Rapidly biodegradable, environmentally compatible oils are usually classified in water hazard class WGK1.

There are now a large number of test methods that assess oils in terms of their degradability or environmental compatibility. This often results in markings which are then listed on the containers or in the data sheets. As described above, well-known labels in Germany and the EU include the "Blue Angel" and the EU ECOLABEL. In the USA, for example, the "USDA Biopreferred" label is widespread.

National or international standards and technical regulations for the classification of rapid biodegradability include:

- Swedish Standard SS 15 54 34 Category V

- ISO 15380, ISO 9439, ISO 14593

- VDMA 24568, VDMA 24570

In particular, ISO 15380, together with ISO 6743-4, specifies four classes of environmentally acceptable hydraulic oils:

- HETG: Triglycerides

- HEPG: Polyglycols

- HEES: Synthetic esters

- HEPR: Polyalfaolefins and other synthetic hydrocarbons.

Some of the properties that speak in favor of the long-term use of HEPR oils in particular are described in ÖlChecker Spring 2009.

Cooperation and Development (OECD) first published guidelines for testing the biodegradability of chemicals. These guidelines, updated in 1993, introduced several test methods, OECD 301 A-F, originally developed for determining the ready biodegradability of single, water-soluble substances manufactured by the detergent industry. Today, however, laboratories worldwide use these OECD Guideline test methods to determine the biodegradation of poorly water-soluble substances and mixtures such as lubricants.

At about the same time, in 1982, the Coordinating European Council (CEC) also developed a standardized test method to determine biodegradation specifically for lubricants. Over the years, this test method has been radically modernized. Due to the implementation of high-temperature gas chromatography, the CEC Technical Development Group developed, tested and approved a new test method in 2012 as "CEC L-103-12 Biodegradability of Lubricants in the Natural Environment."

In the meantime, other organizations, including the International Organisation of Standardisation (ISO) and the American Society for Testing and Materials (ASTM), have also created biodegradation standards that are somewhat similar to the OECD guidelines.

Laboratory biodegradation testing aims to provide a reliable prediction, under controlled, comparable conditions, of how chemicals might behave in the environment. Accordingly, each established test method is composed of three identical basic methodological parts. Each test is prepared in a mineral medium, uses microorganisms, and must contain a test substance. This provides the basis for any biodegradation test for lubricants in an aqueous phase. However, the measurement of degradation allows different points of view. It is possible to monitor both the decrease in the substance used (e.g., lubricant) and the increase in degradation products. Some test methods are based on the removal of organic chemicals measured as dissolved organic carbon (DOC). Others involve the production of carbon dioxide, and still others determine biological oxygen demand or measure inorganic carbon.

In the determination of biodegradability by test method CEC-L-103-12, the sample remaining at the end of the test period is extracted with an organic solvent and gas chromatography (GC) is performed. Using GC as an analytical tool, it is possible to detect what remains of the sample at the end of the test period.

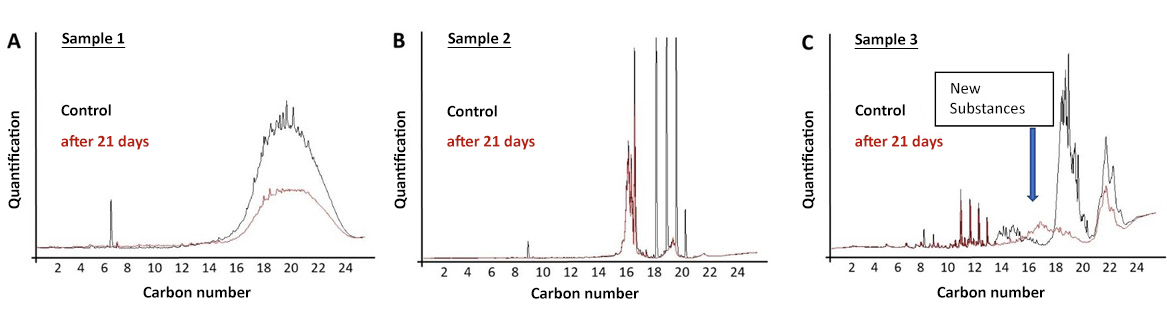

Figure 1 shows example chromatograms of three different samples before (control) and after a biodegradation. Sample 1 shows uniform degradation of all its components (Fig. A), while the chromatogram of sample 2 (Fig. B) shows that after 21 days, some components have degraded more and others less.

An outstanding feature of GC analysis is the detection of new substances that may have been formed during the degradation processes. The analysis of sample 3 shows newly formed substances (Fig. C). An important feature of the CEC-L-103-12 method is its applicability to mixtures of substances, such as most lubricants. However, this test method also has its limitations. For example, it is not suitable for water-soluble, highly volatile substances or lubricants with a boiling range exceeding 600 °C.

The most commonly used test methods for measuring biodegradation represent CO2 evolution tests, e.g. OECD 301 B. These tests are often integrated into guidelines for the award of environmental labels, e. g. "Blue Angel". Here, the carbon dioxide released during biodegradation is measured and expressed as a percentage of the theoretical maximum possible carbon dioxide. Above a threshold value of 60%, a substance is considered to be readily biodegradable. However, this does not allow any conclusions to be drawn about the origin of the carbon dioxide: it cannot be determined whether all components are degraded equally or whether some are degraded preferentially and to a greater extent.

OELCHECK tip:

When selecting a hydraulic fluid for use in an environmentally sensitive area, proceed carefully and check the manufacturer’s specifications, the requirements of the equipment manufacturer, and the regulations of the public authorities in detail. This way you will be on the safe side if anything untoward happens. If you change a system from a hydraulic fluid based on mineral oil to a rapidly biodegradable hydraulic fluid, always pay careful attention to the fluid conversion guidelines. Flushing procedures are necessary because the fluid volume in the tank is usually only around 30% of the total fluid volume. The mineral oil content must be less than 2% after the conversion. This can be checked with the OELCHECK bioset. A higher concentration of mineral oil can cause the bio-oil to lose its rapid biodegradability property.

P. Lohmann, B. Müller, G. Gaule in Synthetics, Mineral Oils and Biobased Lubricants, Chemistry and Technology, Vol. 3 (Eds.: L. R. Rudnick), CRC Press, Boca Raton, 2020, pp. 509–514.