RULER - Determination of the remaining service life of lubricants

Year of publication: 2003

Oils age as well: Reactions of the oil molecules and additives with atmospheric oxygen cause the oils to oxidize. Elevated oil temperatures of over 60 °C, catalytic impurities and intensive air intake accelerate the aging process.

If the oil oxidizes, it ages and its remaining useful life decreases. To slow down this reaction chain and extend the life of the oil, special additives known as oxidation inhibitors or antioxidants are added to the lubricants.

So far, only the oxidation of the mineral oil-based base oils has been determined by infrared spectroscopy by comparison with the fresh oil. With the "RULER", an improved test procedure is available which, in addition to monitoring the base oil, serves in particular to check the antioxidants. OELCHECK has been using one of these test devices since 2003.

RULER is the acronym for Remaining Useful Life Evaluation Routine, a system for determining the remaining useful life of oil. The technology was developed in the mid-1980s to determine the remaining useful life of lubricants in gas turbines and was successfully tested experimentally in A-10 aircraft during the Gulf War.

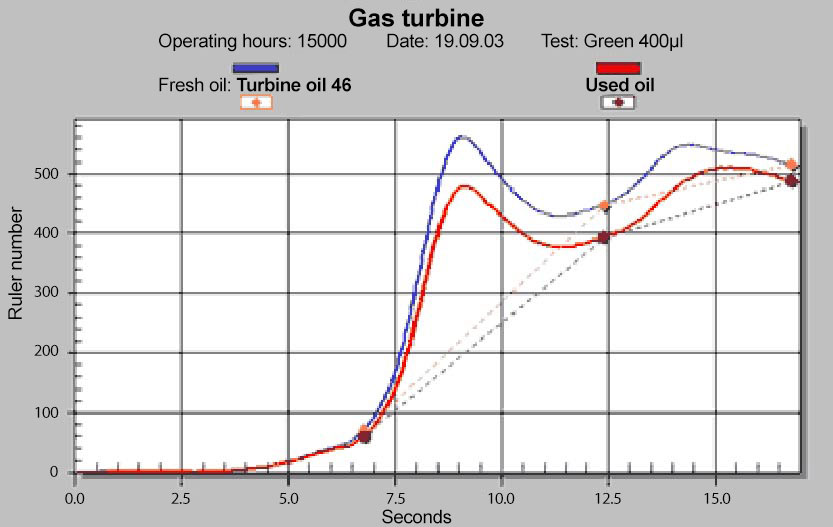

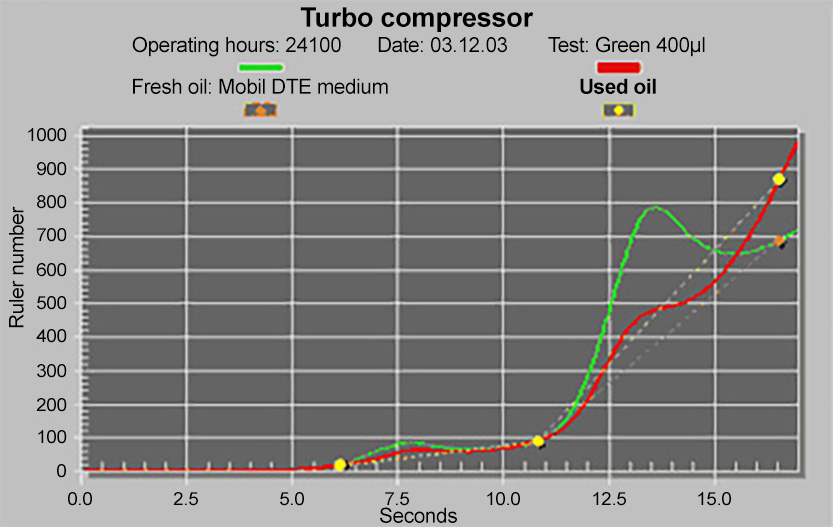

The term "remaining useful life" or residual useful life makes it clear that the RULER device can be used to determine the period of time during which oxidation of the lubricant can still be reliably prevented by the antioxidants added to the oil or grease. The antioxidant content measured with the RULER is directly related to the maximum remaining useful life of the used oil sample. The RULER number decreases as the amount of oxidation inhibitors not yet used decreases.

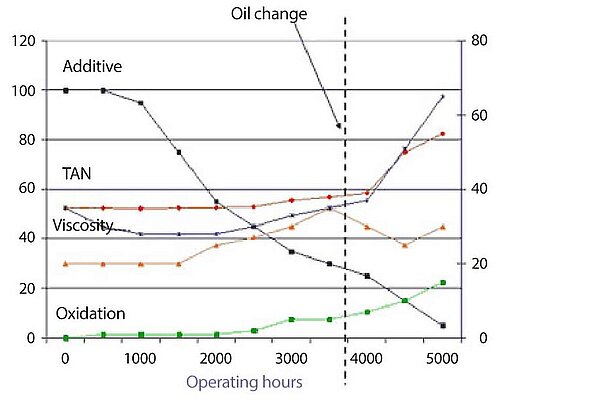

Oil aging and additive degradation increase viscosity and AN (Acid Number) or NZ (Neutralization Number). Lack of antioxidants triggers rapid oxidation. The lubricating properties of the oil deteriorate drastically. Corrosive wear can no longer be prevented.

Figure 1 illustrates the correlations. It shows the development of the measured values of an oil over the course of 5,000 operating hours.

The RULER is used to determine the content of antioxidants in mineral and synthetic oils as well as in all types of lubricating greases. This makes the method suitable both for monitoring fresh oil deliveries for quality control and for inspecting used lubricants.

The testing procedure

The test can be performed with any lubricant containing at least one type of phenol or amine based oxidation inhibitor. In the sample tube, which simulates an electrolytic cell, 0.4 ml of the oil sample is mixed with a solvent and a solid substrate (specially prepared sand with different grain size). By vigorously shaking the sample tube, the solvent separates the antioxidants from the oil. During a short resting period, the solid substrate particles settle at the bottom along with the oil phase and the usual used oil contaminants. Now the sample preparation is complete and an electrode immersed approx. 1 cm in the upper phase of the electrolyte mixture can be screwed onto the sample tube.

In the linear voltammetry method used with the RULER, a defined voltage curve is run across the electrode in the diluted lubricant-electrolyte sample. As the potential rises, the antioxidants become chemically excited, causing a current flow that rises to a maximum value and then falls again as the voltage rises.

The rise and the time course of the voltage are chosen in such a way that the typical curves of antioxidants can be measured particularly well. In the voltage or current curves, the potential of the peak indicates the type of additive and the maximum current flow indicates the concentration of this additive.

The RULER gives a number as measurement result, corresponding to the concentration of the oxidation inhibitor to be measured. This measurement result is compared with the fresh oil sample of a lubricant with the same formulation. By trend analysis or comparison with similar aggregates, it is possible to observe exactly when the quality of the oil drops sharply. On this basis, the remaining service life of the lubricant can now be calculated.

Examples from real life

With a decrease in RULER number, the concentration of antioxidants decreases.

The plant is filled with 1,600 l of an EP turbine oil. OELCHECK has been performing regular lubricant analyses for 3 years. It was found that the phosphorus basic additive level has slowly decreased. However, because there was hardly any change in the AN, it could be assumed that only minor oxidation or aging of the oil had occurred.

However, a routine opening of the gearbox revealed heavy varnish-like deposits on a pair of gears.

As a result, a used and fresh oil sample were immediately examined by OELCHECK using the RULER. Comparison of the analytical data showed very clearly that one of the two oxidation inhibitor types was almost completely degraded. Thus, it became clear that strong local overheating occurs in the gearbox of the turbo compressor, which consumes the phenolic oxidation inhibitor to such an extent that the varnish-like dark deposits are formed on the gear in the places that are warm compared to the environment. Of course, an immediate oil change was advised, because a subsequent adding of additives to the relatively small amount of oil was out of the question.

RULER in use at OELCHECK

The RULER does not replace infrared spectroscopy, which provides information on base oil oxidation and aging. It is used by OELCHECK as an additional tool for determining concentrations of active ingredients intended to reduce aging of the base oil. It is particularly helpful in assessing whether a condition-based oil change needs to be performed.

Based on the RULER number, OELCHECK determines the remaining antioxidant capacity in mineral oil-based turbine oils, synthetic hydraulic and gear oils and in lubricating greases as part of trend analyses. From this, OELCHECK draws conclusions about the optimum intervals for changing the oil or the relubrication intervals for grease, among other things.

Changes in base oils and additives also result in adjustments to lubricant analytics.

Turbine oils based on conventional base oils (API group I) predominantly contained phenolic antioxidants in relatively high concentrations, combined with amines, sulfides or phosphates. Modern turbine oils based on base oils of API Group II (hydrotreated), Group III (hydrocracked) or Group IV (PAO) contain mostly aminic antioxidants combined with phenols, the latter, however, only in low concentrations.

While the measurement of aminic antioxidants in modern turbine oils using RULER still works reliably, the reproducibility of the measurement of phenolic antioxidants is significantly impaired due to the very low concentration.

Phenolic antioxidants by infrared spectroscopy

Extensive studies have shown that phenolic antioxidants can be determined more reliably by FT-IR spectroscopy, especially at low concentrations.

The aminic antioxidants can also be detected by FT-IR. However, the "adjacent" wavenumber ranges exhibit interference with other influences. Nevertheless, the repeatability of the quantitative assessment of aminic antioxidants is compromised. In this case, the determination by means of RULER provides significantly more stable results.

Taking this state of affairs into account, OELCHECK has decided to adapt its monitoring concept. In turbine oils, phenolic antioxidants are determined by FT-IR, and aminic AO by RULER. As before, both values are given in % of residual AO compared to fresh oil.

For you, nothing changes in the basic procedure. However, you will receive results that provide more confidence in interpreting the lab results.