Additives for lubricants

Year of publication: 1999

Additives and their effectiveness are even more difficult to calculate for mechanical engineers and end users than a lubricant without additives. The test methods for the effectiveness of additives are very complex and expensive. At the same time, there are hardly any calculation methods that take their effectiveness into account when designing machine elements. Since there are already hardly any measurable and comparable statements on the effectiveness of the additives for fresh oils, an assessment of the continued serviceability of an additive package or the entire lubricant is all the more difficult. Nevertheless, some standardized analytical methods have been established, which allow the effect of additives to be estimated.

Table of contents

Laboratory analyses for additives

The term "laboratory analyses" is not intended to refer to costly long-term tests with large quantities of lubricant in elaborate mechanical testing machines. The plant operator would like to receive clear information about the effectiveness of the additives. The tests should be inexpensive, fast and precise with a small amount of oil of less than 100 ml. In addition, it must be possible to draw conclusions about the operating method and the remaining service life of the added active ingredients by observing the trend development of the lubricant in the same machine or in similar applications.

| Testing device, method | determines | Measured value | Informs about |

|---|---|---|---|

| AES according to ICP or RDE, XRF | Additive metals: Phosphorus, sulfur, zinc, calcium, magnesium, boron, barium, silicon, molybdenum, sodium | Quantity of the element in mg/kg | Effect of these additives: indirectly via wear; directly by filtering out and depositing of reaction products |

| Viscosity, viscosity index | Viscosity temperature profile | Viscosity in mm²/s, VI | VI improver degradation |

| FT-IR spectroscopy | Comparison with fresh oil, shows deviations in additivation | Oxidation, additive reaction products | Change of molecular compounds, reaction products from additive degradation |

| RULER | Quantity of antioxidants | % of the remaining additive | expected remaining service life of an oil filling |

| BN | Quantity of alkaline additives | Quantity of acid that can be neutralized | Reduction of the neutralization capacity of engine oils |

| AN | Quantity of acidic components | Quantity of KOH required for neutralization | Increase due to reaction products from additive effect and oxidation |

| Foam test | Effect of antifoam additives | Time to degrade surface foam | Presence of anti-foaming additives |

| Fretting corrosion, four ball machine, Brugger | VWear prevention capacity | Material removal from test specimens | Change in the formation of wear domes shows EP properties |

| Spot test | Dispersancy in engine oils | % Dispersancy | Dispersion of dirt and soot particles on a filter |

| PQ index | Magnetizable iron | Quantity of all iron particles | In comparison with the AES statement on corrosion protection behavior |

| OPA | EP and HD properties | Size and shape of abrasion particles | Increased sliding wear indicates inadequate wear protection |

| Pour point, Cloud point | Low temperature improver | When does oil become solid at low temperatures | Effectiveness of pour point depressants to improve low point temperature properties |

| Particle count | Undissolved additives, tribopolymers | Particle number and size | Fresh oil: have all additives gone into solution? Used oil: have reaction products and tribopolymers formed? |

| Optical control | Suspended solids, settling of reaction products | Phase separation | Smeary particles settle in the transparent sample |

| Odor sensors | Decomposition products | Odor change | Spectrum of "odors" developing above the oil level shows additive reactions |

Performance spectrum of additives

Customized additives for modern lubricants

Modern machines and engines place ever higher demands on lubricants, which they have long been unable to meet in their natural form as pure mineral oil. However, chemical agents can be used to specifically modify the properties of lubricants. Today, a carefully formulated combination of active ingredients is added as an "additive" to almost every oil and grease.

According to the set requirements:

- additives improve the positive properties of the base oil, such as wear protection.

- additives reduce or eliminate undesirable properties, such as aging

- additives give the base oil properties that go far beyond its original performance, such as an extended temperature application range.

type, quantity and individual combination of additives depend on the specific application. With their help, customized solutions are created for modern machine and engine technology. The quantity of active ingredients added can be only a few mg/kg (1mg / kg = 0.0001%), as in turbine oils, or high concentrations of up to 20%, as in high-performance engine oils.

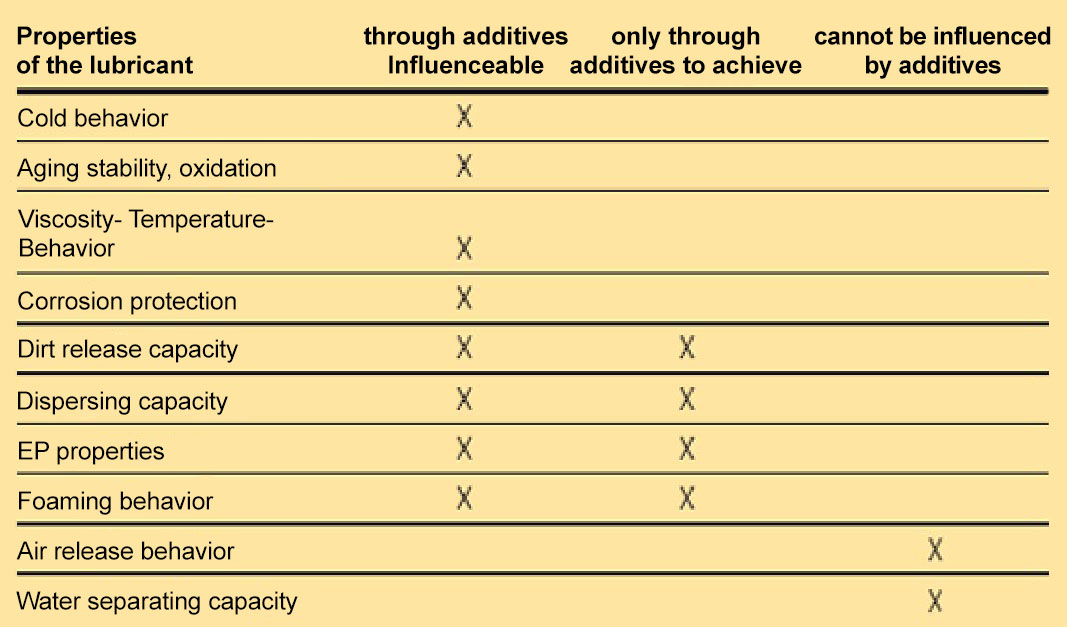

Selected additives can only improve some properties of a lubricant, such as EP behavior. However, not all characteristics of a base oil can be positively influenced.

Optimization of low-temperature behavior

The low-temperature behavior of the lubricant is improved with pour point depressants. The pour point is the temperature at which the oil just flows at sub-zero temperatures. The thickening of the base oil at cold temperatures is caused by the crystallization of the paraffins contained in the mineral oil. Pour point depressants prevent the build-up of these paraffin crystal lattices and thus improve flowability at low temperatures.

Improvement of aging stability

Oxidation inhibitors (antioxidants) delay oil oxidation (oil aging) and the formation of aging products. Oils oxidize when exposed to heat and oxygen. Acids and oil-insoluble components may be produced, forming varnish-like deposits such as resins and sludge. The viscosity of the oil often increases. The aging of an oil usually starts very slowly when oxidation inhibitors slow down this process. The active ingredients intercept the reactive molecules (radicals) and neutralize oxygen-containing compounds. Thus, they protect the lubricating oil from the rapidly increasing attack. However, once these additives have been used up, the aging of the oil proceeds unchecked, just as with unadditivated oil. This process is further accelerated by traces of contaminants, such as metallic abrasion, water or dust.

Viscosity-temperature behavior

Viscosity index improvers (VI-Improvers) increase the viscosity index of the oil. Especially at high temperatures, they prevent the oil from becoming very thin. The mineral oil becomes less sensitive to temperature. It is only through the use of these additives that modern multigrade engine oils, hydraulic oils and gear oils achieve a viscosity-temperature behavior that meets the requirements of the engines and machine elements.

Corrosion protection

Corrosion inhibitors create a protective film on metallic surfaces. They prevent the access of water or oxygen to the surface of the material and neutralize acidic reaction products from additive degradation or oxidation. In this way, they prevent the formation of a corrosive attack on non-ferrous metals. If their protection relates specifically to ferrous metals or steel, they are also referred to as rust inhibitors.

Dirt dissolving properties

Detergents dissolve contaminants, which are caused by the aging process of the oil due to combustion in the engine or by impurities, into fine particles. They are particularly effective against sludge and varnish-like deposits that have developed on the basis of soot, acid compounds, nitrogen oxides, unburned fuel residues and water, thus keeping piston rings or the oil pan clean by their "washing" action.

Dispersancy

Dispersants are the indispensable counterpart to detergents. They keep the detached contaminants in suspension and ensure that they cannot form new deposits. In doing so, they literally envelop the dirt particles and enable them to be transported to the filter.

EP properties

EP and AW (anti-wear) additives build up extremely thin protective layers on the sliding surfaces of the materials. They can influence the roughness of the surfaces by forming reaction layers. The mechanical load-bearing capacity in the contact zone is then improved by the larger load-bearing component of the surfaces. EP and AW additives reduce wear and galling (localized welding) under severe operating conditions, shock loading, vibration and frequent start-stop operation.

Foaming tendency

Antifoaming additives, usually based on silicone, are added during production, especially to oils with a high additive content. Foam can nevertheless be caused by false air from the oil pump, contamination or incompatibility with other oils. Surface foam can also be destroyed subsequently with silicone-containing solutions. However, there is a risk that it will be stabilized as air bubbles in the oil. This eliminates surface foam, but this dissolved air can cause cavitation and corrosion.

Additive elements in the OELCHECK laboratory report

In each OELCHECK laboratory report, metals contained as chemical compounds in the lubricant are indicated under the heading "Additives". The quantitative comparison of the determined used oil values with the additives from the fresh oil provides information on additive degradation. It should be noted, however, that the elements were not only added to the fresh oil during oil production as organometallic additives to improve certain properties. In some cases, they may have entered the oil in a completely different way. If the additive specifications in the laboratory report deviate from the values, the OELCHECK engineers comment on the reason for such a change. The components used as additives that can be detected by atomic emission spectroscopy (AES) are listed in the following overview. This includes a description of their mode of operation and an indication of how they can enter the lubricant if they are not included in the additive.

Lead

Used to be added to gear oils in particular as wear protection. No longer used today as an additive! Component of plain bearings, non-ferrous metal alloys (bronze), solders.

Molybdenum

EP additives in the form of oil-soluble organometallic compounds or as solid-containing, dark gray MoS2 oil additives To reduce friction (friction modifier) and wear. Metal made of high-strength alloys, e.g. piston rings.

Potassium

Usually not an oil additive but an additive for aqueous media, such as antifreeze glycol, cooling water, metalworking emulsions. Also contained in road salt and tap water.

Boron

To improve the cleanliness of engines. But mostly emulsion or cooling water additive. Alloy component of "glycol". Additive in gear oils for special friction characteristics.

Magnesium

Improves the thermal stability of hydraulic and engine oils. Increases the alkaline reserve (BN) of engine oils. Rather rare: Hardness components in tap water (besides calcium).

Calcium

Detergent (cleaning) additive especially in diesel engine oils and HLP-D hydraulic oils. Also improves thermal resistance. Sometimes "chalk dust" from construction sites or from cooling and tap water.

Barium

To improve the EP properties. Detergent (removing) and dispersant (dirt carrying) effect in engine oils. Friction modifiers in ATFs. As barium complex soap component of high temperature greases or assembly pastes.

Phosphorus

Occurs in almost all "alloyed" or additivated oils. Best known EP high-pressure additive (usually in combination with zinc or sulfur). To reduce wear and prevent galling. Abrasion of bonderized or phosphated surfaces.

Zinc

Wear-reducing high-pressure additive. Reduces friction at the same time (friction modifier). Abrasion from zinc-containing components, paint coatings or from hose material. With ester oils (bio-oils): galvanized components can be attacked by hydrolysis.

Sodium

Mostly contamination in the form of road salt or from salty air near the sea. Additive in water-containing liquids. Tap water component. Anti-corrosion additive in oil or antifreeze glycol (non-ferrous metal protection).

Silicon

Prevents foaming of lubricating oils (anti-foaming silicone additive). In most cases, however, dust from the environment. In gas engines also from the gas condensate. Abrasion of silicone seals, residue from silicone greases or release agents.