Grease analysis

Rolling and glide bearings, constant-velocity joints and open chainwheel drives generally have one thing in common: they are lubricated with grease. This applies in particular to more than 80% of rolling bearings, which are available in many different forms. Lubricating grease is involved in 75% of bearing failure incidents. For example, the grease may be contaminated, bled out, oxidised or aged, burdened with wear particles, or simply not present in an adequate amount. The good news is that if you use OELCHECK lubricating grease analyses to stay informed of the condition of the lubricating grease concerned, you can take countermeasures promptly and avoid failures. Over 10% of the samples processed every day by OELCHECK (as many as 2,000) involve lubricating greases – which must be assessed just as thoroughly and reliably as oils, coolants and fuels. However, lubricating grease analysis is not straightforward due to the small sample volumes, and only a few labs worldwide are able to do this. One of them is OELCHECK. We have laboratory equipment that has been adapted to our wishes, as well as many years of experience in the assessment of grease samples.

Table of contents

- Brief: Lubricating greases

- Your ace for bearing lubrication: OELCHECK lubricating grease analyses

- All-inclusive analysis kits: for all applications and all issues

- Kit 1: The elements

- Kit 2: Kit 1 + iron particles and base oil modification

- Kit 3: Kit 2 + quantitative water content

- Kit 4: Kit 3 + residual oil content & bleeding test

- Kit 5: Kit 4 + penetration number:

Brief: Lubricating greases

Lubricating greases are commonly used in situations where a lubricating surface cannot be perfectly supplied with oil. In addition to providing optimal lubrication, in many cases lubricating greases must also seal lubricating surfaces and protect moving parts against wear and contamination. They should attenuate shock loads, and ideally they should be suitable for lifetime lubrication. However, there are limits to what greases can do. Unlike liquid oils, they are not able to dissipate high temperatures or remove contaminants and wear particles from the friction surface. Lubricating greases are manufactured by stirring a liquid base oil into a suitable thickener. Additives, and in some cases solid lubricants, are mixed in to reduce friction and provide wear protection. Lubricating greases contain 70 to 95% base oil, 3 to 30% thickener, 0 to 10% additives, and at most 10% solid lubricants. As the main ingredient of a grease, the base oil essentially determines its lubricating and performance properties. Mineral oils, synthetic oils, and in some cases vegetable oils are used as base oils. Thickeners are divided into metallic soaps (such as lithium, sodium, calcium, barium or aluminium) and non-metallic soaps (such as bentonite, polymer resin or silica gel). As carriers for the base oil, they form a cross-linked, sponge-like structure. This structure holds the oil and releases it to the lubricating surface in a controlled manner. Certain properties of a lubricating grease can be strengthened and/or specifically modified by additives. If a grease has to work under especially severe conditions or have emergency running properties, solid lubricants such as graphite, molybdenum disulphide (MoS2) or PTFE (Teflon) are additionally mixed in. A grease containing more than 40% solid lubricants is called a paste.

Your ace for bearing lubrication: OELCHECK lubricating grease analyses

- Detect bearing wear and its causes at an early stage

- Distinguish between mechanical and corrosion wear

- Timely warning of lubricant oxidation and ageing

- Identify contaminants and their origins

- Detect mixing with other greases

- Helps with the optimisation of lubricant amounts and relubrication intervals

Lubricating grease analyses from OELCHECK make a major contribution to operational reliability and have a positive impact on maintenance costs.

All-inclusive analysis kits: for all applications and all issues

The handy OELCHECK all-inclusive analysis kits are a good choice for testing lubricating greases. However, the values provided by the test parameters in kits 1 and 2 are only suitable for trend analyses and assessment of fresh greases. For analysis of used grease with kits 3, 4 or 5, additional tests are performed to enable OELCHECK tribologists to make a comprehensive assessment. All-inclusive analysis kits 3 and 5 are specifically matched to the corresponding applications and issues. Our OELCHECK tribologists will be pleased to answer your questions about choosing the right analysis kit!

Kit 1: The elements

After visual evaluation and photography of the lid, the sampling tube and the sample bottle, we determine more than 20 elements for every lubricating grease sample. Along with wear and contamination particles, we examine the active ingredients and additives already present in the fresh grease. Using atomic emission spectroscopy (AES) with the rotating disc electrode method, in which a small amount of grease is applied to a target turntable, up to 21 elements are determined quantitatively and stated in the lab report in units of mg/kg (ppm). These values are divided into three categories: wear elements, contaminants and additives.

- Typical wear elements:

Iron, chromium, tin, copper, lead, nickel, aluminium, molybdenum and zinc, as well as concentrations of vanadium, titanium, silver, antimony, manganese and tungsten. Elevated iron and chromium values, for example, indicate wear of a rolling bearing. Copper and zinc indicate wear of a brass bearing cage.

- Typical contaminants:

Silicon, calcium, sodium, potassium, aluminium, cadmium and bismuth. Silicon (dust) and calcium (lime) in particular, as deposits from hard water, can promote wear. Sodium can also come from salt water and cause corrosion wear.

- Typical additives and thickeners:

Lithium, magnesium, calcium, phosphorus, zinc, barium, silicon, aluminium, molybdenum and boron. Their values are compared to those of the fresh grease. A change relative to a previous sample or the fresh grease can indicate mixing or reduced grease performance.

Kit 2: Kit 1 + iron particles and base oil modification

In addition to the element values in kit 1, OELCHECK includes the Particle Quantifier (PQ) index in the scope of all-inclusive analysis kit 2 to identify even the smallest iron particles that can still be magnetised. AES is not able to stimulate particles larger than 2 μm strongly enough for reproducible indication. By contrast, the PQ index includes all particles present in the grease that are able to react to a magnetic field. Our OELCHECK tribologists know the relationships between the determined iron content in ppm and the PQ index and are able to make clear statements regarding the condition of the bearing concerned.

- For example, a high iron value with a relatively low PQ index is a sign of corrosion. Rust particles are barely magnetic, but they are so small that they can be measured with AES.

- A high PQ index together with a low AES value is a sign of contamination or material fatigue.

Furthermore, in kit 2 and above the base oil type and its modification by water or temperature is determined using FT-IR spectroscopy. The base oil is usually the main ingredient of a lubricating grease, with a share of more than 80%. The thermal characteristics and oxidation resistance of the base oil are decisive for the working temperature range of the grease, and in part for its ageing characteristics. Fourier transform infrared (FT-IR) spectroscopy is based on the fact that the molecules in a grease absorb infrared light at specific wavelengths to different degrees due to their typical bond types. The Fourier transform makes the values readable, and the molecular vibrations can be shown in an FT-IR diagram. This produces peaks at relevant wave numbers, depending on the molecular bond. The deviations of the peaks at specific wave numbers can be recognised by comparing the FT-IR diagram of a used grease with the diagram of the fresh version of the same grease. Our OELCHECK tribologists can draw clear conclusions from this. FT-IR spectroscopy gives them the following indications:

- Whether the examined grease contains a mineral or synthetic base oil

- Whether a different type of grease than expected has been used

- If greases have been mixed or the wrong grease was used for relubrication

- Potential additive deterioration if the grease contains high-pressure additives, for example based on zinc phosphate compounds

- Any water penetration greater than 1%

- Whether a mineral oil-based grease has been oxidised and aged due to exposure to high temperature or lack of relubrication

However, when ester-based components are used, FT-IR spectroscopy cannot provide unambiguous information about their oxidation because the oxygen molecules present in the ester absorb infrared light in the same wave number region as the oxygen double bonds resulting from oxidation. In this case FT-IR spectroscopy meets its limits. As an alternative, a RULER test in an OELCHECK lab indicates whether the grease concerned has been overheated.

Kit 3: Kit 2 + quantitative water content

If too much water penetrates into a lubricating grease, more frequent relubrication is necessary. However, that is the least of the problems. If the grease cannot withstand the water, the soap structure changes and the grease becomes weak and soupy. In many cases the seals cannot contain the grease and it leaks out. If a grease is burdened with too much water, there is a risk of rust and corrosion, leading to bearing damage. On lubricating surfaces with high relative motion, water-induced cavitation often occurs.

All-inclusive lubricating grease kits 3 to 5 include determination of the exact water content in ppm using titration according to the elaborate Karl Fischer method. Too much water in the grease (more than 150 ppm) can have serious consequences. In the Karl Fischer method, a small amount of grease is weighed into a tube that can be hermetically closed. The water is then slowly driven out of the grease in a lab oven at a temperature of 120 °C.

The evaporated water, together with nitrogen, is fed through a hollow needle to a titration tube. There it reacts electrochemically with a specific solution. The water content of the grease in ppm (mg/kg) can be read precisely from the inflection point of the titration curve. When assessing the analysis results, the OELCHECK tribologists also consider the relationship between the water content and the element values determined by AES. From that they can often see whether the water came from condensation, rain, tap water or salt water. This makes it easier for the customer on site to stop the water penetration. If the grease is contaminated with calcium, potassium, sodium and/or magnesium, that is usually a sign of hard tap water. In many cases, water has penetrated from high-pressure cleaning. If the above-mentioned elements are only present in low concentrations in the used grease, that is usually a sign of ‚soft‘ condensation or rainwater. If the sodium share clearly predominates, the water is probably salt water.

Kit 4: Kit 3 + residual oil content & bleeding test

As you might guess, bleeding out is not a good situation for a lubricating grease. When a grease bleeds out, it loses a considerable part of the base oil necessary for lubrication. If there is not enough oil present in a used grease, the impact can be dramatic. In the production of a lubricating grease, a boiled thickening agent, called the soap, is added to a base oil. The thickener holds the base oil in its sponge-like structure and slowly releases the oil to the lubricating surface. „Bleeding out“ means that the oil flows too quickly and uncontrollably from the thickener structure. The grease dries out and can no longer perform its lubrication tasks. In many practical cases, excessive loss of base oil from a grease is initially only noticeable from strong oil fouling of the seal area and a need for more frequent relubrication. In such cases an immediate examination of the grease using OELCHECK all-inclusive kit 4 is recommended. In addition to the analysis methods in kits 1 to 3, it includes determination of the residual oil content. For that purpose, the grease sample is heated to 60˚C in the OELCHECK lab and held at that temperature for six hours. The percentage of the base oil lost from the thickener structure during this period is then determined. After that, the value for the used grease is compared to the value for the fresh grease. The following conclusions can usually be drawn from the results:

- Base oil loss between 5 and 25%:

The grease can continue to be used without any change to the relubrication interval.

- Base oil loss significantly higher than 25%:

- The grease is no longer suitable for use. To avoid damage, the causes must be determined promptly.

- Due to high shaft speeds, loads or vibrations, the grease is simply unsuitable and its working temperature range is too low.

- There have been errors in handling. The relubrication amount was too small. Incompatible greases were mixed. The grease was used for too long or not relubricated. In that case, the base oil is usually also oxidised or aged.

- The grease is contaminated with water, acids or alkalis.

- Base oil loss less than 5%: If very little base oil escapes from the used grease, that is also not a good sign. In many cases, the grease has already been bled nearly dry. The bearing surface is starved of lubrication. Relubrication as quickly as possible is therefore necessary, or the relubrication interval must be shortened. It should also be checked if the grease that is being used is basically suitable for the task.

Kit 5: Kit 4 + penetration number:

With all-inclusive lubricating grease kit 5, the OELCHECK tribologists can comprehensively describe the condition of the grease and the lubricated component. Kit 5 is based on the tests of the previous kits, augmented by determination of the consistency by means of the penetration number. The consistency number expresses the relative stiffness of lubricating greases. Lubricating greases are assigned to nine consistency classes according to the classification system of the US National Lubricating and Grease Institute (NLGI). This makes it easy to see, for example, if a grease can be easily pumped through a central lubrication system. However, the grease consistency can change during use. If it becomes significantly stiffer or softer, there is a risk to the component lubricated by the grease. That‘s why determination of the penetration number, and with it the consistency, is included in the scope of OELCHECK all-inclusive analysis kit 5.

| NLGI classes | Penetration number | Consistency at room temperature |

|---|---|---|

| 000 | 445 - 475 | Very liquid |

| 00 | 400 - 430 | Liquid |

| 0 | 355 - 385 | Semi-liquid |

| 1 | 310 - 340 | Very soft |

| 2 | 265 - 295 | Soft |

| 3 | 220 - 250 | Semi-solid |

| 4 | 175 - 205 | Solid |

| 5 | 130 - 160 | Very solid |

| 6 | 85 - 115 | Extremely solid |

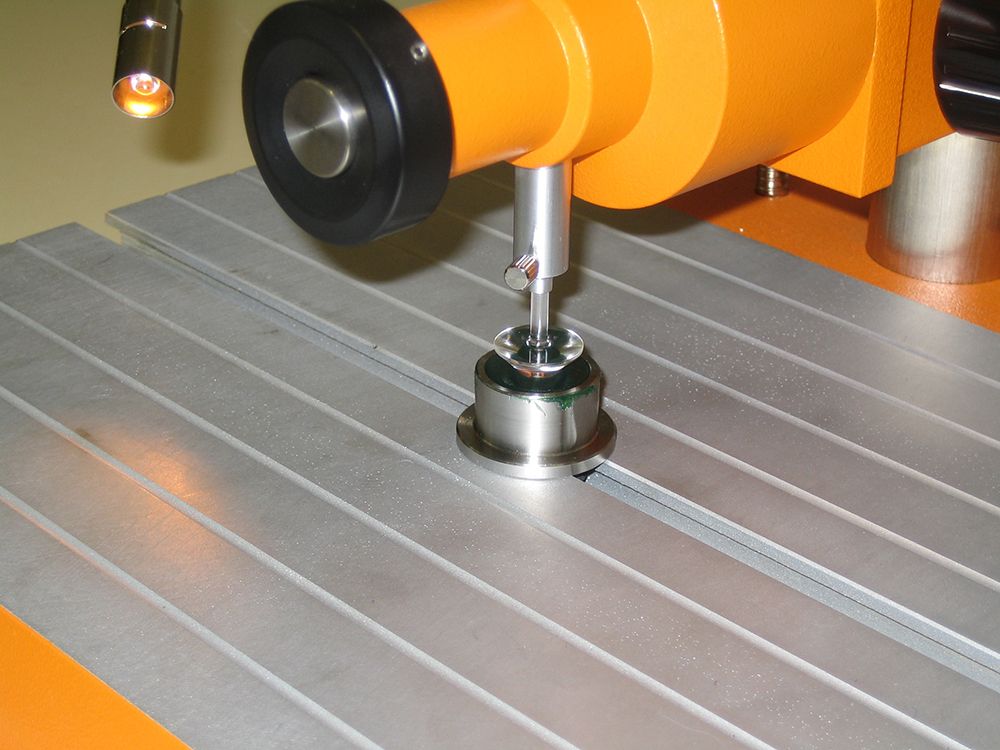

The penetration number is determined by pressing a standardised cone into a specific amount of grease. At the start of the test, the tip of the cone is just touching the surface of the grease. The cone then penetrates deeper. Its penetration depth after five seconds is measured in units of 0.1 mm. That gives the penetration number, which in turn determines the consistency class of the grease. The softer the grease, the deeper the cone penetrates. The penetration number is high, and the NLGI class is low. OELCHECK compares the consistency classes or penetration numbers of the used grease and the corresponding fresh grease. That leads to the following conclusions: Higher penetration number = Softer consistency, lower NLGI class: The grease may be contaminated with water or another liquid. Mixing with a grease that has a different thickener or base oil type. The grease has been exposed to high loads and mechanically sheared. Lower penetration number = Stiffer consistency, higher NLGI class: The grease has become stiffer due to a lack of relubrication or bleeding. Excessive loading by vibrations and/or working temperature range too high. The pumping pressure of the central lubrication system is too high; the pipe cross section is too small.

OELCHECKER Winter 2018, pages 4 - 6