Transformers, their oils and gas-in-oil analysis

Year of publication: 2024

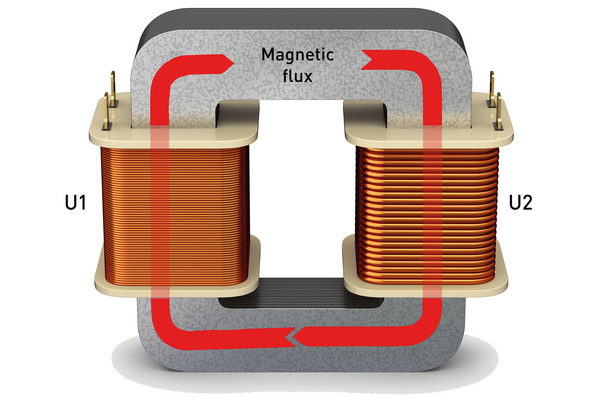

Large transformers are performance-critical components of the power supply network. A transformer consists – put simply – of a magnetic circuit, an iron core around which the conductors of at least two adjacent circuits are routed in coils, usually with different numbers of windings.

In order to insulate the live parts, the copper wires are varnished with synthetic resin or wrapped in films or special papers. The transformers are filled with insulating oils based on mineral oil, ester oil or silicone oil for additional protection against potential voltage surges. These oils must not only insulate, but also cool, be resistant to low temperatures and oxidation and harmonise with the winding and insulating materials.

Transformer oils are used for years and age slowly. However, if electrical and/or thermal faults occur in the transformer, this will cause the oils and insulating materials, especially the special papers, to decompose. These fault events generate gases. These are soluble in the oil like air from the atmosphere up to a certain concentration. Gas-in-oil analysis determines and quantifies these gases. Every OELCHECK analysis set for transformer oils also includes a gas-in-oil analysis. The values determined and their diagnosis are recorded in the laboratory report according to an evaluation procedure described in the VDE standard.

Depending on the type and intensity of the gases dissolved in the oil, the different types of faults in the transformer can be identified based on the results. This in turn allows conclusions to be drawn about the consequences for the oil, paper insulation and the transformer itself. Ultimately, gas-in-oil analyses make a decisive contribution to the operational safety of the transformers and the energy supply.

OELCHECKER Winter 2024, page10