Complex terms – simply explained

The latest article

AdBlue® and damage to SCR catalytic converters

Year of publication: 2024

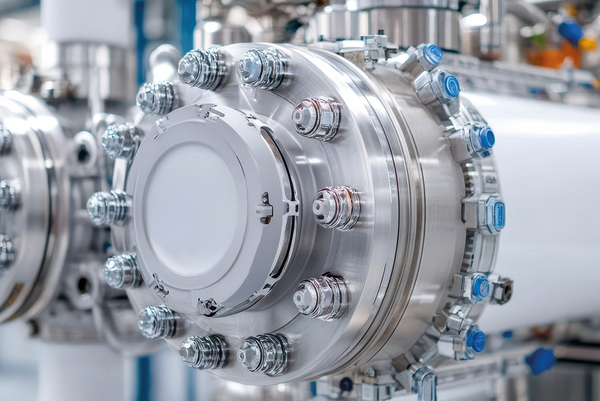

AdBlue® is the technical prerequisite for operating modern diesel engines with exhaust gas after-treatment systems. However, if the AdBlue® used is “contaminated” or “unclean”, it can become a serious hazard to the SCR catalytic converters (selective catalytic reduction). In the OELCHECK laboratory, high-precision analysis is therefore not only used to check AdBlue® quality, but can also help in the event of problems or even damage to SCR catalytic converters related to the use of urea solution. The values determined in the laboratory clearly indicate the causes. And it is becoming increasingly clear: In many cases, the specifications for the correct use of the urea solution have not been observed!

- Acids in the oil

- AdBlue – a cleaning agent with no residual alcohol

- AdBlue® and damage to SCR catalytic converters

- Air and foam in oil

- Air-release properties & foaming tendency

- Atomic Emission Spectroscopy (AES)

- Cloudpoint & Pourpoint

- Cold Filter Plugging Point (CFPP)

- Density temperature profile (DTP)

- Dispersancy

- Filter deposits

- Fire-resistant HFC hydraulic fluids

- Fluxes and coolants – Not the best of friends

- Glycol determination

- Increased oil consumption

- IR Index

- Limit values at OELCHECK

- Low SAPS or low ash

- Lubricants in the food industry

- Nitration

- NN, AN and BN

- Oil aging

- Oil condition

- Oxidation

- Oxidation index – Modern lubricants age differently

- Oxidationsinhibitoren (Antioxidants) – Elixirs of life for modern lubricants

- Phenolic inhibitor

- Pour point and solidifying point

- PQ index

- Refractive index

- Strong Acid Number

- Sulfation

- Synthetic lubricants – types, properties and applications

- Transformers, their oils and gas-in-oil analysis

- Trend analyses - An investment in the future

- VI - The viscosity index

- Viscosity

- Viscosity-temperature profile (VTP)

- Wear metals in lubricants