Glycol determination

FT infrared spectroscopy – On the trail of oxidation

Infrared spectroscopy is one of the most important analyses in used oil evaluation and is therefore a standard feature of all OELCHECK analysis kits.

IR spectroscopy is used to detect impurities in the lubricant and to identify mixing. Furthermore, it determines the condition of the oil in terms of oxidation, nitration and sulfation.

By comparing the fresh oil with the used oil, IR spectroscopy provides information about oil oxidation, nitration and sulfation. Soot, fuel content and water are converted and expressed as a percentage. Glycol from the cooling water is detected. Even with an unknown oil, IR spectroscopy delivers an amazingly good fresh oil assignment and accurate values by comparing the used oil with the fresh oils in the database via a "reverse search".

Which individual values are determined at which "bands" of the IR spectrum for the lubricant depends on the type and use of the lubricant. Below you can see an overview of causes for an IR spectrum to change and their possible effects.

Antifreeze glycol (for all oils)

In the event of cooling circuit leaks, the glycol added to the water as cooler and antifreeze protection can enter the lubrication circuit.

Reasons

- Cracks in the cooling water circuit

- Corroded solder joints on oil cooler

- Defective seals between cylinder head and engine block

- Leakage at "wet bushings”

- Refill bottle contaminated with glycol

Effects

- Extremely high thickening of the oil with increasing oil temperature and longer operating time

- Deposits in lubrication holes up to clogging

- Corrosive attack of non-ferrous metals and bearing materials, especially copper, lead and tin

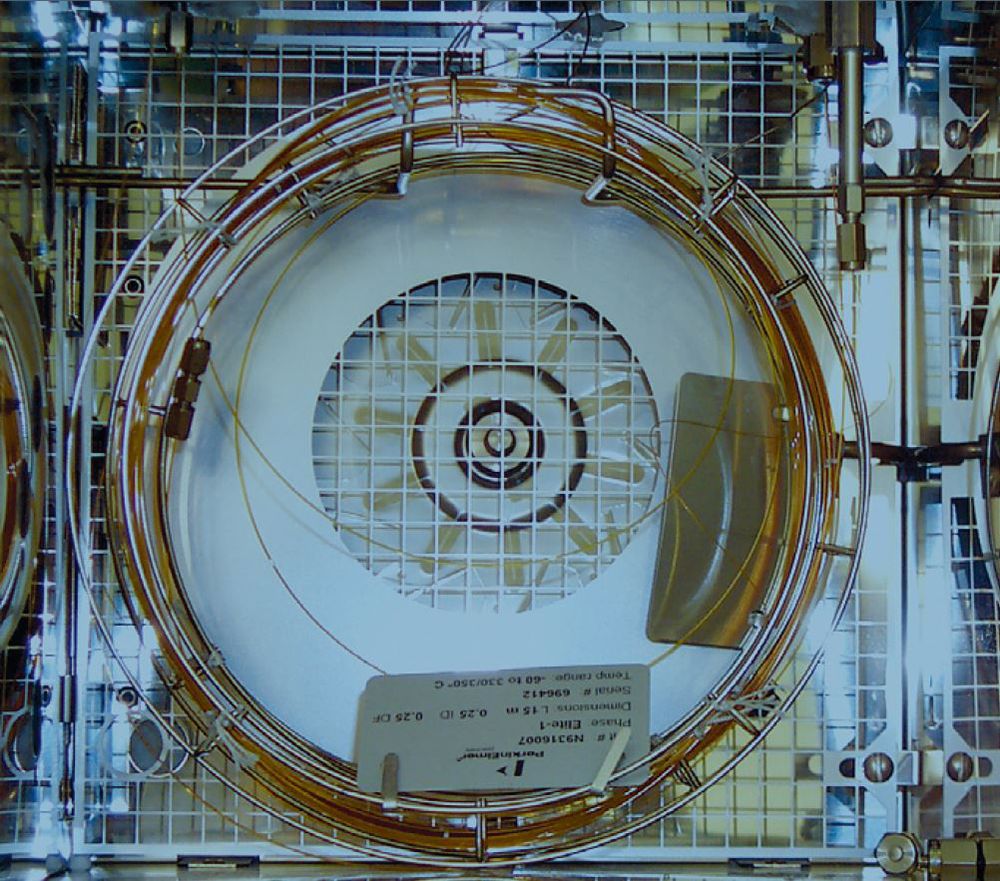

Glycol determination by means of gas chromatographic analysis

Especially in engines, it is possible that initially very low levels of coolant enter the engine or transmission oils. However, the entry almost always increases with higher thermal load. Based on the glycol content, determined by gas chromatographic analysis, even the smallest amounts can be detected - especially if this is not yet possible by means of IR spectroscopy. A defect can thus be detected earlier and damage and repair costs can be kept low.