PQ index

The dimensionless PQ index, the Particle Quantifier index, for oil and grease samples is mentioned in every OELCHECK laboratory report under the rubric “Wear”. This value informs about magnetisable iron abrasion in the sample and is an important supplement to the also declared value for iron content in mg/kg. The iron content is determined with ICP spectrometry, but this only works if the particles are smaller than 5 µm. By contrast, the PQ refers to the total amount of magnetisable iron particles in the sample. Especially for oil samples from gears, diesel engines and hydraulic systems as well as grease samples, it provides useful information on abnormal and mostly acute wear processes. The two values are interpreted together, because the PQ index together with the iron value provides information about the size distribution of the iron particles. Important conclusions concerning the condition of the installation can be drawn from the combination of both results.

The PQ test principle (according to ASTM D8184)

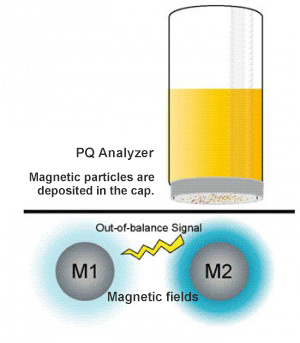

The determination of the PQ index makes use of the phenomenon that iron introduced into a magnetic field becomes magnetized, thereby amplifying the magnetic field. In the PQ meter, two magnetic coils, a measuring coil and a reference coil, are in magnetic equilibrium. If a sample contains magnetic iron particles, these act as an iron core in the magnetic field of the measuring coil. Their magnetic field is amplified. This amplified magnetic field acts on the reference coil, which detects the change in the magnetic field. The disturbance of the equilibrium between the measuring and reference coils is indicated as an index. The PQ instrument is calibrated with a sample with PQ=0 and a sample PQ=750. Based on this 2-point calibration, the index for the sample is calculated. PQ values below 25 do not yet provide a clear indication of existing wear. Therefore, we simply specify "< 25" for values below 25.

The samples are initially stored upside down for 20 minutes. This allows all iron particles contained in the oil to settle on the white seal of the flat lid. The robot of the Analex PQ analyser (Kittiwake Developments) then places the sample on a turntable, which moves the sample evenly over the measuring coil. Depending on the amount of contained iron particles, the magnetic field is strengthened and the balance with the reference coil is disturbed. The measured out of balance signal is directly proportionate to the content of iron particles in the sample, irrespective of their size or number.

Conclusion

The PQ index is dimensionless. No indication of the iron content is made in a unit of measurement, e.g. mg/kg. It is not possible to convert the value proportionate to the amount of iron particles in a gearbox, for example. The PQ index generally increases with an increasing content of magnetisable iron. PQ values below 25 are an indication of normal wear. The iron particles are primarily extremely small and are scarcely deposited in the oil so that other methods can be used for quantitative determination. In the laboratory report, PQ values below 25 are indicated with an „OK“. Values above this are shown as figures in the laboratory report. These indicate an increased iron content. What is to be assessed as increased depends on the respective application. In large-volume systems (e. g. turbines), a value below 50 can already be critical; in highly loaded gear units, even a value in the triple-digit range can still be unproblematic. Furthermore, grease-lubricated applications are generally to be considered differently than oil-lubricated ones.

With incorrect sampling in which oil with a high iron particle content was taken from a filter bowl, for example, index values far above 5,000 were measured. The PQ index shows its full potential only when viewed together with the iron content determined in ICP spectrometry. By a comparison of the PQ index with the value for iron content, which is determined by the AES, conclusions can be drawn whether the iron is abrasive, magnetisable wear or nonmagnetic ferric oxide (rust) or iron sulphide (through oil additives). When interpreting the PQ index with the value for iron content the following connections can be recognized:

Increased PQ index - increased iron content

„Normal“ wear. Both values are approximately the same. This suggests continually progressing wear processes, which are mostly dependent on the operating time.

High PQ index - slightly increased iron content

„Acute“ wear. Iron particles can have different causes, e.g. pitting, erosion or chipping in the form of larger particles. Damage can be prevented by taking corrective measures in good time in particular when abnormal wear processes are indicated.

Slightly increased PQ index - high iron content

„Corrosive“ wear. Iron particles, e.g. rust and corrosion particles introduced into the oil through water, are not magnetisable. These are often so small that they do not readily settle in highly viscous gear oil. At a high iron value, not accompanied by a high PQ index, strong corrosive wear can be concluded in almost all cases.

ÖlChecker Spring 2011, page 8