| OELCHECK test instrument: | Copper strips and warming bath |

| Sample quantity: | 50 ml |

| Unit: | none |

| Test result: | corrosion level 1 – 4 |

| Analysis for: | mineral oil products and greases |

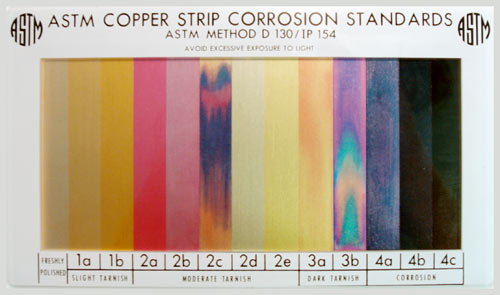

| Brief description: | A smoothed, polished and degreased copper strip is dipped into a sample container containing the fluid for investigation. When greases are investigated, the copper strip is smeared with the grease on every side and is then placed in a sample bottle containing the same grease. The closed sample bottle is then stored for a certain amount of time in a warming bath. Once the test period has finished, the copper strip is removed, cleaned with solvent and dried carefully. The level of corrosion at the end of the experiment is ascertained by comparing the copper strip with a colour scale. The result is placed in one of four main categories (1-4) and, within these, two to five sub-categories (a-e). |

| Statement: | The procedure determines the corrosive effects of lubricating oils and greases on copper. Corrosion to metal is based on factors including but not limited to sulphur compounds in the oil. However, this also depends on the sulphur species present. The absolute sulphur content alone does not allow any conclusions to be drawn about the corrosion that can be expected from metallic components when using fuels or lubricants. |

| Underlying test standard: | DIN EN ISO 2160, DIN 51811, ASTM D4048 |

| Deviating methods: | ASTM D849: applies to aromatic hydrocarbons |

| Comparable methods: | ASTM D130: performed at OELCHECK without pressure tanks |