| OELCHECK test instrument: | four-ball apparatus |

| Sample quantity: | approx. 100 ml |

| Unit: | Newton, mm, % |

| Test result: | VKA welding load, calotte diameter and shear stability (KRL test) |

| Result range: | 2,000 N to 12,000 N, > 0.22 mm |

| Analysis for: | industrial oils, lubricating greases and metal processing oils with high pressure loads |

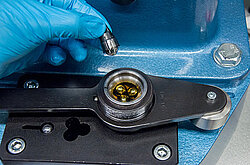

| Brief description: | The test apparatus consists of one rotating ball and three stationary balls, a drive unit and a load arm carrying the test weights. The material and diameter of the balls is standardised. The stationary balls are held in a cup. The cup is filled with the lubricant to be tested (10 ml), completely covering the stationary balls with lubricant. A horizontal arm supported on the casing prevents the cup rotating. A vertically mounted test spindle is located over the cup. There is a bracket for the rotating ball held in a ball holder at its lower end. The test spindle is driven by an electric motor and rotates at 1,450 min-1. A circuit breaker interrupts the power supply once the test balls are welded together and prevent rotation. The lever mechanism for applying the test load is accommodated in the bottom part of the casing. The test load is adjusted by varying the weights applied and the lever length. The test load is applied directly to the cup through a vertical ram, pressing the stationary balls against the rotating ball. |

| Statement: | The method is used in particular for lubricants which must withstand great loads and pressures. They therefore contain active substances (EP additives) intended to allow high pressures in the mixed friction area. The VKA value is stated in N (newtons) for the property and weld load. The higher this VKA value of an oil or grease, the better its lubricating effect under pressure loading. For comparison: the weld load of a conventional industrial gear oil, CLP 320, is around 2,200 N. Values in excess of 3,600 N can be achieved by modern synthetic high performance gear oil of the same viscosity class. Alternatively, the test can be carried out in such a way as to determine the anti-wear behaviour of a lubricant at lower forces and for a longer test time. A VKA test is indispensable in the development and quality control of oils and greases which must be very stable under pressure. Additionally, if the situation in the testing equipment is only transferable into practice to a limited degree, the VKA test represents an important basis for the assessment of the lubricating effect of a lubricant under high pressure loading. The simple and cost-effective test thus permits direct conclusions to be drawn regarding the performance of the various EP additives and anti-wear agents. |

| Underlying test standard: | DIN 51350 part 1-5 |

| Deviating methods: | ASTM D4172 (oils, 1200 rotations/minute) ASTM D2266 (greases, 1200 rotations/minute) ASTM D2783 (1760 rotations/minute, determination load wear index) |