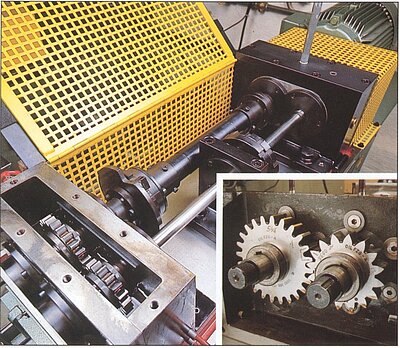

| Test instrument: | gear test rig |

| Sample quantity: | 3.0 l |

| Unit: | scuffing load stage |

| Result range: | scuffing load stage 1 - 12 |

| Analysis for: | lubricants |

| Brief description: | The scuffing load capacity of lubricants is determined on the FZG gear wheel tension testing machine. A test gear pair with a special tooth geometry runs in the testing lubricating oil according to the immersion lubrication method. The temperature and speed are specified. The load on the tooth flanks is gradually loaded via a lever loaded with weights, which clamps one of the shafts against the other. From load stage 4, the pinion tooth flanks are inspected for any damage after each power stage. Changes are documented. If a defined damage pattern occurs or load stage 12 is reached without the damage pattern occurring, the measurement is completed. The requirement standard for hydraulic oil (DIN 51524-2 HLP), for example, requires at least load stage 10; the requirement standard for circulating oils (DIN 51517-3 CLP), for example, requires at least load stage 12. Part 2 of the associated standard (DIN ISO 14635) is geared towards high EP-alloyed lubricating oils. In comparison to the test according to Part 1, a higher peripheral speed and a higher temperature are used. |

| Statement: | Scuffing is a severe form of tooth flank damage. It occurs when, especially in mixed friction conditions, the roughness peaks of the surfaces are briefly welded together and torn apart again by the relative movement and load. The test procedure provides a statement on the scuffing load capacity of a lubricating oil. The scuffing load capacity is understood to be the greatest load which, under specified conditions, does not lead to a failure of the gear wheel due to scuffing wear. |

| Underlying test standard: | DIN ISO 14635-1 (standard) DIN ISO 14635-2 (high EP alloyed lubricating oils) |