Prosthesis fittings such as ankle or knee joints are small technical marvels. Össur develops all its products with the goal to allow as much natural functionality as possible for artificial limbs. The company operates five research and development centres in which comprehensive research is performed across various topical fields.

Knowledge from various specialist fields must also be integrated into the German development facility in order to ensure that new products meet expectations. Among other things, these specialist areas include orthopaedic technology, gait analysis, general mechanical engineering, hydraulics, pneumatics, CAD construction, materials science, plastics engineering, chemistry, textile engineering or also test technology and test station construction. The development site in Bayreuth operates a mechanical laboratory, an orthopaedic test workshop and a 3D gait laboratory. Thus, user and processing tests as well as studies can be performed there.

Prostheses are subsequently manufactured in medical facilities from modular fittings created by Össur. Suitable modules are installed with an individually manufactured prosthesis shaft in order to precisely adapt the prosthesis to the user’s requirements.

At Össur, each load-bearing fitting is dynamically tested for three million steps. Ultimately, prostheses fittings must perform reliably under all conditions in order to support the wearer in everyday life. In sports as well, countless sprinters, jumpers, throwers, triathletes, marathon runners and swimmers have been successfully equipped with Össur prosthesis fittings. Only prosthesis fittings for children must withstand greater stresses since a child may, e.g., climb a tree and then decide to jump down.

The human knee is a highly complex joint. Stability and safety are the top priority when replacing the knee with a prosthesis fitting. However, the artificial knee should also move as physiologically as possible, which means that the lower leg on the side of the prosthesis should behave exactly as the still existing lower leg when moving at various speeds. For a majority of products, movements are controlled hydraulically. A small, fully configurable hydraulic cylinder performs similar tasks as the shock absorber of a vehicle. However, the cylinder does not absorb impacts but attenuates the rotational movement.

The Bayreuth facility cooperates with OELCHECK since Össur regards hydraulic oil as a central structural element. For example, the hydraulic oils of two knee joints have already been subjected to certain examinations.

The Össur Cheetah® Knee is one of these highly stressable joints with hydraulic swing phase control.

It was specifically developed for quick flexing and extension while running and sprinting. The 4-axle geometry offers good stability in the standing phase as microhydraulics allow for the configuration of a maximum flexion angle, prevent hard impacts while extended and alleviate walking and the transition from walking to jogging or running.

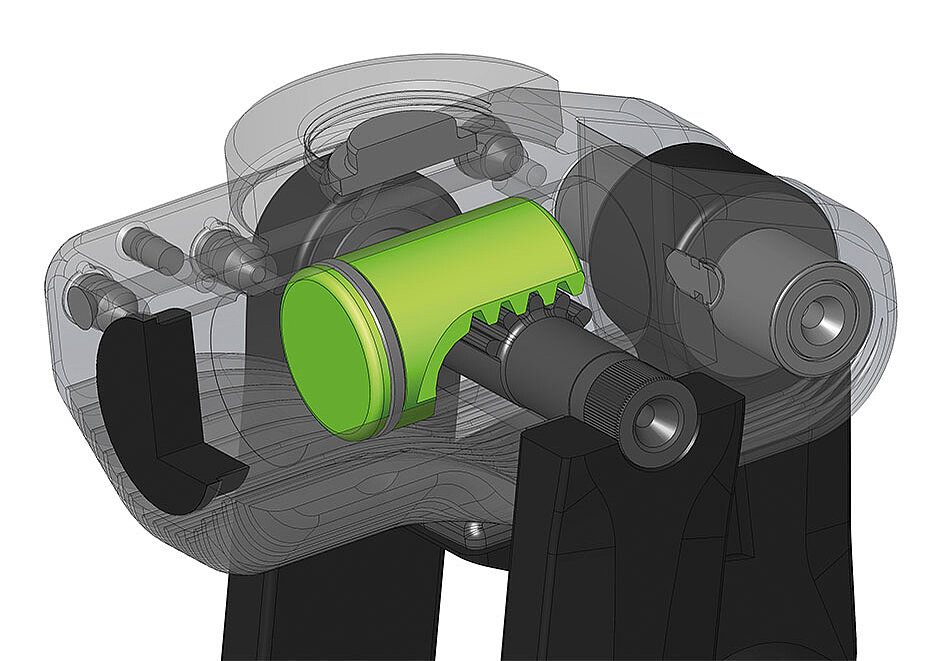

Microhydraulics installed in the Cheetah® Knee allow for a separate regulation of the attenuation degree in the flexion and extension direction via valves at the outside of the knee joint. The hydraulics chamber has a toothed rack combined with a toothed segment so that the linear piston movement can be converted into a rotational movement.

Heat can build up quickly inside the artificial knee. The joint head can reach a temperature of up to 80 °C during fast running, and joints would heat up even more without the cooling ribs in the lower joint area.

Microhydraulics are filled with approx. 25 ml or three tablespoons of a special kind of hydraulic fluid. However, despite the little amount, the fluid provides optimal performance. The Össur Cheetah® Knee is also used by marathon runners, which suggest that the fluid is able to withstand tremendous stresses over a long period of time. Small bubbles with oxygenic air form when diffused air cannot quickly escape from the oil. Self-ignition occurs if these bubbles are highly compressed due to the high pressure that can occur within the hydraulics of a knee joint. The oil, which contains hydrocarbon reacts with the oxygen in the air bubbles. Analogous to the self-igniting diesel motor, isolated and incomplete combustion occurs due to insufficient oxygen. Soot particles form from this “diesel effect” that can give the oil a black colouration within a very short period of time.

The toothed segment in the hydraulic chamber poses another challenge. Premature wear can occur if fluid performance is insufficient. Wear can even lead to breaks in the toothed segment and, in the worst-case scenario, block the joint causing the runner with the prosthesis to fall.

Safe functionality of hydraulic knee joints crucially depends on the used fluid. However, requirements placed on oils are consistently increasing as the trend is towards smaller, lighter and more efficient hydraulic units, which in turn exposes oils to greater pressures and temperatures.

Össur cooperates with OELCHECK for each new development so that the optimal fluid is used right from the start. Many aspects are inspected during oil analysis. Among other things, the analysis also focusses on viscosity, viscosity temperature behaviour, EP wear protection, lubrication performance, pressure absorption and air output capacity, oxidation and ageing behaviour over a long period of time as well as compatibility with various materials and media.

Founded in 1971, Össur is presently a market leader in non-invasive orthopaedics and the industry’s innovation leader. The company has a staff of over 3,000 employees who develop worldwide solutions for the requirements of users, orthopaedic engineers and medical staff. With headquarters in Iceland, the company also has a comprehensive global presence with additional sales centres in Europe, America, Asia and beyond. Össur operates according to strict and effective quality controls that comply with the requirements of ISO 9001 and ISO 13485 quality management standards.