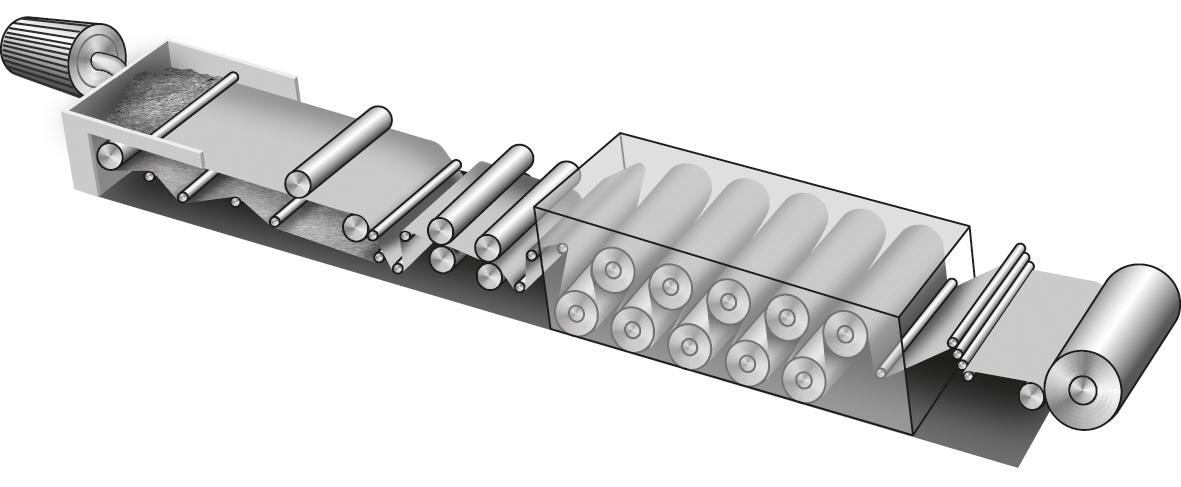

Plant fibres are processed into pulp with water. The fibre pulp is sifted, drained, pressed and dried. The paper manufacturing process has changed since its beginnings. Today, modern machines are used for paper manufacture, producing endless paper webs around the clock in contrast to the manual process in which each sheet was created individually.

The machines used today produce 1,800 meters of paper per minute under extreme conditions. Used lubricants are exposed to an air humidity of 90 %, an ambient temperature of up to 80 °C and fine paper dust. The oil volume of a paper machine will often hold more than 10,000 litres of oil in order to ensure long oil change intervals. However, oil-related machine malfunctions cause large-scale economic damage not only due to long downtimes but also on account of the required oil change, which is why a regular analysis of used lubricants is important. OELCHECK recommends performing an oil change every three months.

OELCHECK now offers a special analysis kit for the optimal monitoring of gear oils, circulating oils, hydraulic fluids, heat transfer oils and greases for paper machines. The set with a mint green cap has the appropriate analysis scope – for any component.

We have already created these kind of industry solutions for gas motors and wind power stations. Based on broad approval from our customers with respect to previous innovations, we have now decided to expand these products to paper machines. Of course, you can continue to use your previously acquired analysis kits.