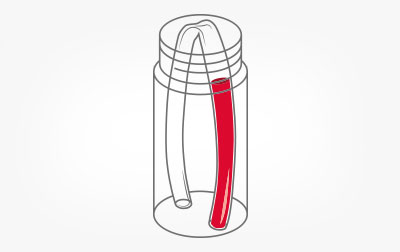

OELCHECK offers a specific "Grease sampling kit" containing the following equipment:

Along with our grease sampling kit for taking grease samples, we recommend using our all-inclusive analysis kits for lubricating grease, which contain the following:

Note: The best diagnostic results are achieved if the data from a new grease sample can be compared with the used grease.

Samples for trend analyses should always be taken from the same spot.

If it is not possible to take a sample using the syringe, you can use one of the spatulas.

Procedure with bearing removed

Draw the used grease out of the cage area and between the rolling elements into the tube or remove the grease in this area with a spatula.

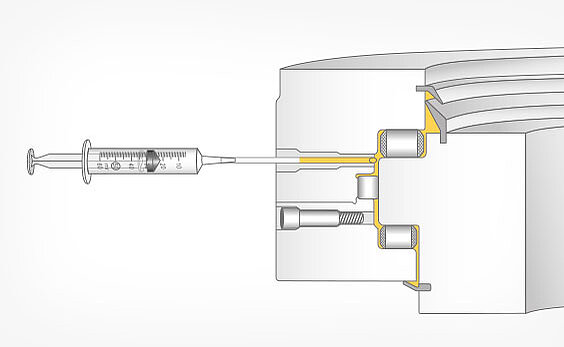

Procedure with bearing attached

Remove the lubricating nipple or disconnect the oiler or the central oiler pipe. The tube supplied usually fits through the 10 mm thread hole. Draw the lubricating grease into the tube. Check visually, based on changes in colour and structure, that the tube mainly contains used grease.

Procedure for large roller bearings (diameter -> 1,000 mm)

Remove the grease from the sampling openings provided, which are usually closed during operation. The sampling points should, where possible, be on the raceways in the main load-carrying area. For the best possible results, take samples from several points and mix these together in the sample bottle.