| OELCHECK test instrument: | test ring |

| Sample quantity: | approx. 1 g |

| Unit: | oil loss: % by weight dot diameter: mm |

| Test result: | oil loss dot diameter |

| Analysis for: | lubricating greases |

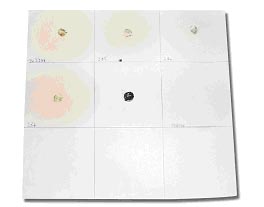

| Brief description: | The test ring, evenly filled with approx. 1 g grease, is placed on a filter paper and put in the oven for 6 hours at 80 °C. The weight of the ring after the testing procedure in comparison to the weight of the sample taken indicates the oil loss. The diameter of the dot which appears on the paper is measured. A photo is taken of the dot. |

| Statement: | The amount of leaking oil which remains in the used grease is diagnosed in comparison with the values for new grease. If too much oil is bled in comparison with new grease, the grease has become soft and "soupy", due to water, for example, or the thickening agent being destroyed by mixing. If, by contrast, too little oil is bled, the grease is oxidised or "dried" by other factors, such as a lack of relubrication intervals or bleeding caused by significant oscillation strain. As such, this procedure is of particular interest, as it allows valid conclusions to be drawn in instances where many standardised tests cannot be performed due to a lack of used grease. |

| Underlying test standard: | OELCHECK test method OPM 038 |