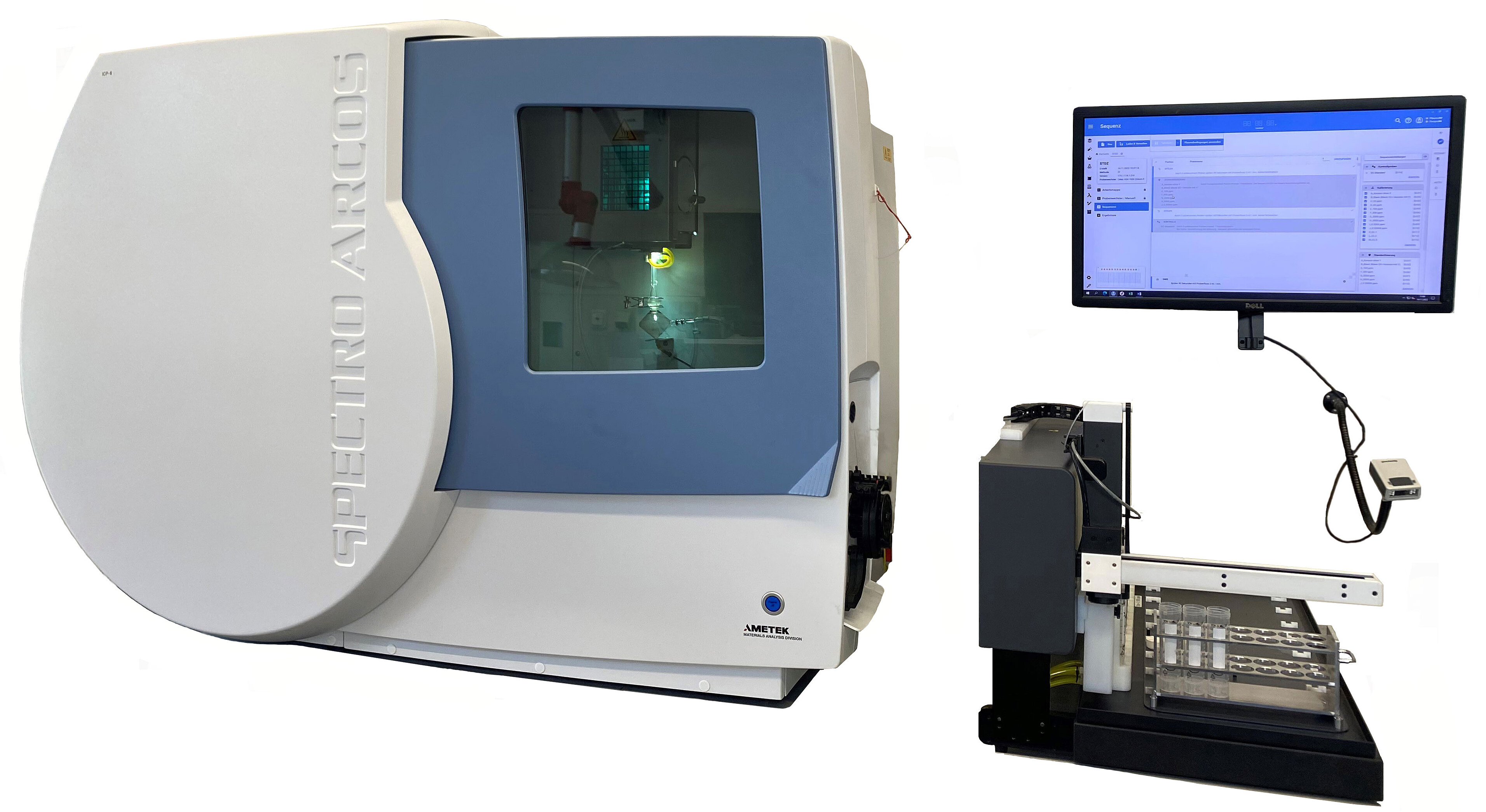

| OELCHECK test instrument: | Spectro Arcos ICP-OES |

| Sample quantity: | 5 ml |

| Unit: | mg/kg (1,000 mg/kg = 1,000 ppm = 0.1% by weight) |

| Test result: | aluminium, barium, lead, boron, chromium, iron, potassium, calcium, copper, magnesium, molybdenum, sodium, nickel, phosphorus, sulphur, silicon, zinc, tin Indicated if the values are over 1 mg/kg: manganese, silver, titanium, vanadium |

| Result range: | 0 - 5,000 ppm |

| Analysis for: | diesel fuel |

| Brief description: | The samples are stirred thoroughly in a sample changer, before being pumped into the nebuliser with a peristaltic pump. They are then atomised with an argon flow. The aerosol then enters a cyclone chamber where the large drops are removed. The aerosol, now prepared, enters the plasma, a mixture of atoms, ions and electrons. The temperature is approx. 10,000 °C. This extremely hot plasma provides the energy to stimulate the individual elements. The resulting radiation emitted, which has a characteristic wavelength for each individual element, is spread out spectrally and detected with a CCD chip. This allows an entire emission spectrum to be absorbed. |

| Statement: | The ICP procedure can identify over 30 wear metals, contaminants and additives with an optimum detection limit. Contaminants can give important clues to possible problems. If certain elements – typical for additives – are found, this can be an indication of possible contamination, e.g. with engine oil or in some cases with oil from a hydraulic system. If e.g. iron is found in the elemental analysis, this may be an indication of corrosion or the addition of iron-containing fuel additives. |

| Underlying test standard: | OELCHECK test method OPM 046 |