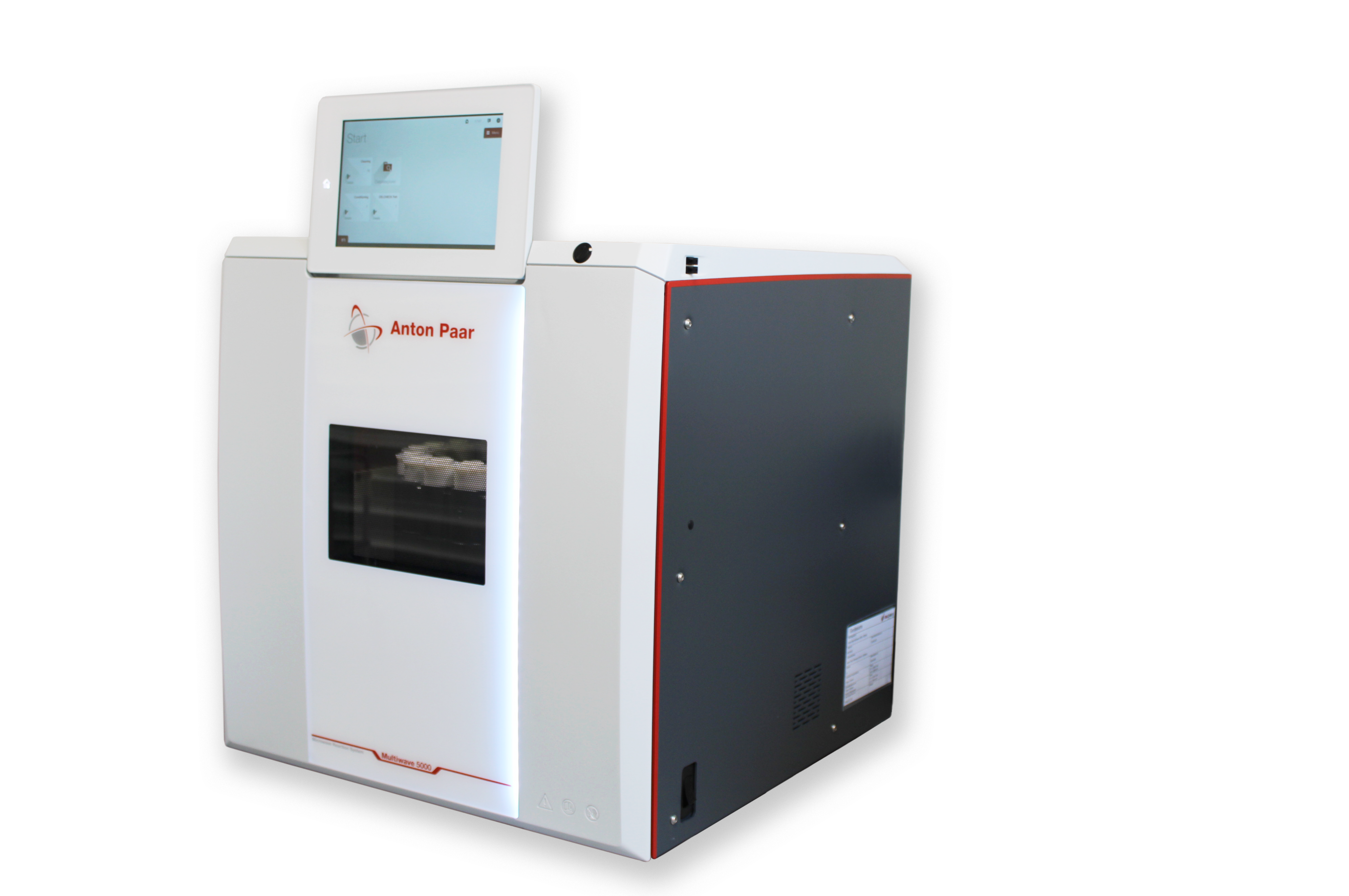

| OELCHECK test instrument: | Anton Paar Multiwave 5000, Spectro Arcos II ICP-OES |

| Sample quantity: | 1 g |

| Unit: | mg/kg |

| Test result: | aluminium, barium, lead, boron, chromium, iron, potassium, calcium, copper, lithium, magnesium, manganese, molybdenum, sodium, nickel, phosphorus, silicon, zinc, tin |

| Analysis for: | Lubricating greases |

| Brief description: | For elemental determination in lubricating greases by means of optical emission spectrometer with inductively coupled plasma (ICP-OES), sample preparation is necessary. The samples are digested with microwave assistance. For this purpose, the sample is weighed into a pressure vessel and nitric acid is added. In the microwave, digestion of the organic matrix and the contained metals takes place at high pressure and temperature and under oxidizing conditions. The aqueous digestion solution is measured directly by ICP-OES. A peristaltic pump feeds the digestion solution into the nebulizer. An argon stream nebulizes the sample into an aerosol. The large droplets are removed in the spray chamber. The aerosol thus prepared now enters the plasma, a mixture of atoms, ions and electrons. The extremely hot plasma of about 10,000°C excites the individual elements. The excited elements emit radiation with characteristic wavelengths for each individual element. The emission lines are spread out and a CMOS chip is used to detect the intensity. A full emission spectrum is recorded simultaneously. In this way, the element contents of the samples are determined with previously established calibration lines. |

| Statement: | The grease ICP method determines up to 27 wear metals, impurities and additives, a.o. from the grease thickener. Through sample preparation, components of digested particles can also be found in the sample. The wear metals present in grease are important data carriers. Their presence allows conclusions to be drawn about the wear of the components or machine elements from which the particles could originate. It does not matter whether the wear is corrosive or mechanical. |

| Underlying test standard: | DIN 51460-1 |