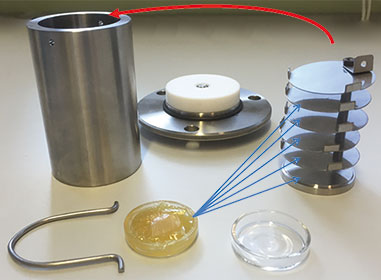

| OELCHECK test instrument: | RPVOT test devices with additional grease sampling apparatus |

| Sample quantity: | 25 g |

| Unit: | psi |

| Result range: | oxidation stability |

| Analysis for: | greases |

| Brief description: | During the test, the lubricating grease is exposed to pure oxygen inside a hermetically sealed pressure chamber at an elevated temperature. The oxygen is consumed by the process of oxidation, which in turn lowers the pressure in the pressure chamber. Given that there are oxidation inhibitors in the lubricating grease, this drop in pressure can be prevented for as long as the additives can buffer the oxygen. Ageing is simulated for a specified time (typically 100 or 200 h). The result is a drop in pressure during this period. The oxidative stability of the lubricating grease as a whole is determined, not just that of the separated base oil. The values that are ascertained from this process indicate the oxidative stability of the grease in its practical application. The longer it takes for the drop in pressure to register, the better equipped the grease is against premature ageing. |

| Statement: | An increasing number of lubricating greases are used for long-term or even lifetime lubrication. Grease manufacturers and OEM design engineers in particular should know the oxidative stability of the relevant greases in advance. Ultimately, a long-lasting grease will age, too. High temperatures and ambient oxygen above all cause the grease to oxidise. It is not always possible to assess a fresh grease in a complex roller bearing test, for example the FE 8 with a test run with 10 bearings. To ensure that consistent information on oxidation-related relubrication intervals can be provided, OELCHECK also tests the oxidative stability of lubricating greases. |

| Underlying test standard: | ASTM D942 |