As an alternative, combined heat and power plants have been installed; these operate using gas obtained from burning wood or pellets. However, the gases contain nitrogen and large amounts of tar. No gas engine oil is able to absorb these extreme contaminants. Consequently, the engines are highly susceptible to damage. Agnion Technologies GmbH, Pfaffenhofen has now developed a new energy generating plant technology for the production of environmentally-friendly energy. With Agnion‘s Heatpipe Reformer technology, syngas can be produced from wood. Downstream processes allow syngas to be used for high temperature heat, biomethane and electricity. The first Heatpipe Reformer has been undergoing practical tests since 2009. The ground-breaking ceremony for the first commercial installation is scheduled for April 2011. The employed gas engine oils and in turn the engines are monitored by regular lubricant analyses by OELCHECK.

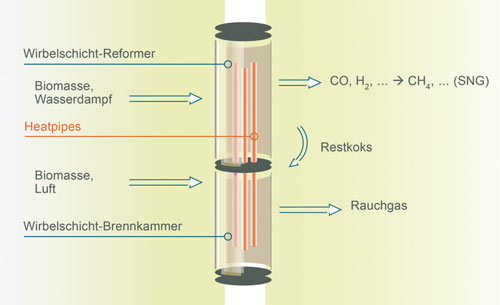

The new technology consists of an allothermic gasification of solid biomass. The Heatpipe Reformer consists of three core components: a fluidised bed reformer, heat pipes and a fluidised bed combustion chamber.

The solid fuel enters the actual fluidised bed gasifier, the reformer, via a lock system. In a fluidised bed of this type, a sand bed is held in suspension by a gas flow. In the Heatpipe Reformer, steam serves this purpose. In this fluidised, highly turbulent sand bed, fuel particles are optimally mixed and at temperatures of around 800°C, begin to convert into a gas mixture consisting predominantly of hydrogen and carbon monoxide (syngas).

The major innovation of the Heatpipe Reformer concept is that the central problem of heat input is resolved very simply with so-called heat pipes. This concept enables the required flows of heat to be transferred between combustion chamber and reformer at a low temperature gradient and high specific output. This allows the allothermic gasifier to be designed especially simple, cost-effective and compact. In the allothermic reforming process, biomass forms with water vapour a syngas consisting of about 40% hydrogen (H2) and 20% carbon monoxide (CO). Parallel reactions additionally produce about 20% carbon dioxide, 10% methane (CH4), water vapour and small amounts of higher hydrocarbons, so-called tars.

The clean and methane-rich gas is ideal for the operation of gas engines. Not only can it be converted into electricity in the engine, but synthetic natural gas can also be produced through CO separation. However, special gases such as biogas, mine gas or landfill gas have previously posed a challenge for engines. In addition to contaminants and hydrogen sulphide in the gas, the sulphurous acids produced in the combustion process are a significant problem. The engine oil must absorb and neutralise these acidic components and the hydrogen sulphide to prevent damage to the gas engine.

The gas produced with the Heatpipe Reformer also contains small amounts of sulphur. To what extent these affect the engine oil and how the alkaline reserve in the engine oil behaves is closely examined in accompanying lubricant analyses by OELCHECK. The AN (Acid Number or neutralisation number) is a measure for the degree of oil acidification. The BN (Base Number) indicates the content of alkaline additives in the oil. This is a significant criterion for determining how many acidic components can still be neutralised and rendered harmless by the oil. Accordingly, the BN should always be higher than the AN. In gas engines which operate with variable gas qualities the initial pH provides additional information on the degree of acidification. In lubricant analysis, the general condition of the oil as well as contained wear elements and contaminants are determined. These have a profound effect on the useful life of the oil and provide important information on the condition of the engine.

Agnion was established in 2007. Today, the group has 30 employees. As a result of its own development activities, over 30 inventions have been filed for patent since 2008. The first commercial installation in Achental will have a thermal input of 1.3 MW and supply 360 kW electricity and 600 kW heat. It will therefore have a total efficiency of 75%. Whereas pellets will be used in the pilot installation, woodchip will be used in Achental. Apart from ash, which can be disposed of normally, the fuel leaves no residues.

There are plans to install 100 installations in Bavaria over the next few years; industrial and waste wood, straw and hay will serve as fuel. If further development goes to plan, Agnion Heatpipe Reformer technology will represent a sustainable and at the same time a lucrative method for decentralised energy supply. Finally, unlike wind and solar energy, this technology does not require any investment in storage capacity and electricity grid.

related links