The systems for processing waste wood as wood chips for heating systems or chipboard are becoming increasingly important. However, their operating conditions pose a number of challenges, especially for the gearboxes of the systems and their oils. For this reason, Doppstadt always sends a sample of the gear and hydraulic oils to the OELCHECK laboratory for analysis during every system maintenance.

In times of a shortage of raw materials and energy shortages, waste wood is increasingly being used as a valuable resource. Depending on the level of quality, waste wood is used for energy purposes, such as combustion in biomass power plants or as a material in the wood materials industry. Waste wood is industrial waste wood from wood working and processing companies, residues of composite materials and used wood from a wide range of sources. In order to make waste wood usable, it must be prepared. This is no easy task, because it is not only simple wooden pallets that have to be processed, but often also window frames, doors, cable drums and even railway sleepers. However, Doppstadt’s special systems break everything down and master a wide range of challenges. They work efficiently and achieve high quality and throughput with low operating costs. This allows them to fully exploit the potential of wood as a recyclable material.

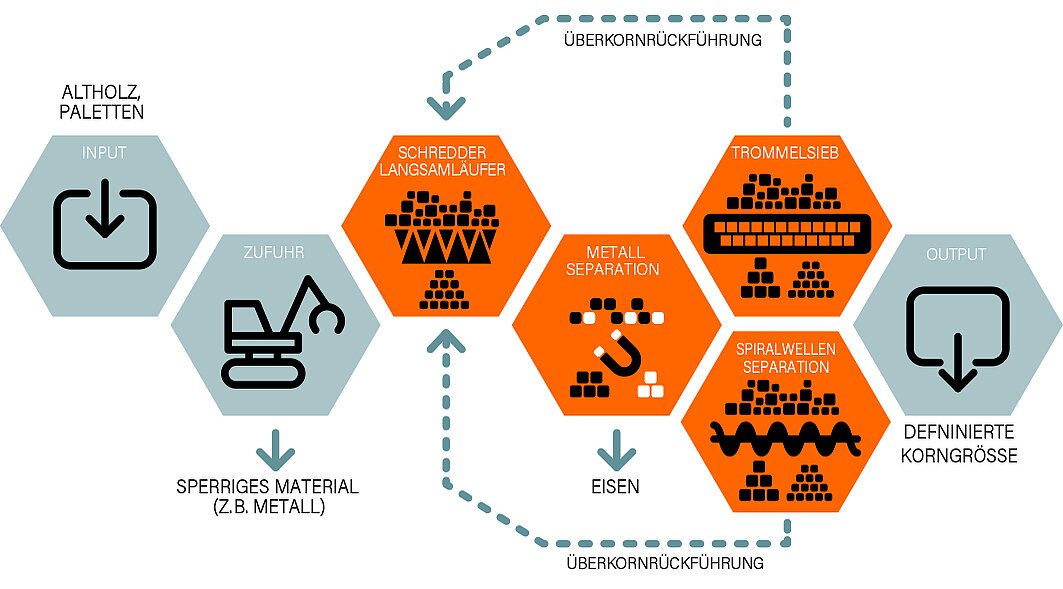

Doppstadt offers both mobile-modular and stationary high-performance complete solutions that precisely match the requirements on site and can be integrated into existing components – including impressive services for future-proof, successful operation. Whether mobile or stationary, the optimally combined units shred waste wood, remove magnetisable metal parts and sift through different material sizes. All this is done without interruption in a single operation.

During mobile use on site, slow-moving shredders from the Doppstadt INVENTHOR series take on the heavy work of shredding. The machines reliably pre-shred the material with high torque. They feature an effective drive train with high power reserves, intelligent material feed and configurable shredding systems. Designed accordingly, they achieve an output of 90,000 t per year, even with large material flows.

For example, an INVENTHOR 9 equipped with a crawler trolley weighs 35,000 kg. In the working position, it is over 16 m long and 3 m wide. Thanks to the crawler trolley, the INVENTHOR 9 can change its position on site automatically. Its diesel engine meets the EU Stage V emissions standard and, with its 530 hp, ensures enormous power.

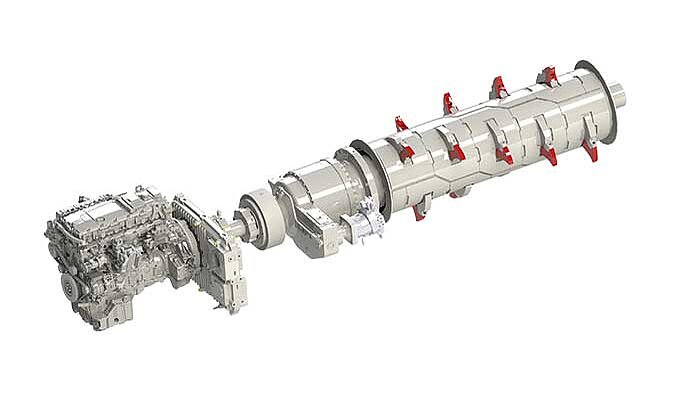

The INVENTHOR is based on Doppstadt’s proven single-roll principle. The highlight of the model series is the patented VarioDirect Drive installed as standard. The unique direct drive concept impresses with high efficiency, optimum torque and low fuel consumption. Thanks to hydraulic support, the drive force can be transferred variably to the shredding roller and thus offers ideal possibilities for effective shredding. This means that the speed of the roller can be flexibly adjusted to the shredding task or even reversed, while the motor operates highly efficiently at a constant speed.

The patented VarioDirect Drive, a power-split planetary gear, transfers the relatively high motor speed to a low roller speed of 5 to 32 min -1. Depending on the size of the unit, the gearbox is supplied with 50 l to 250 l of a synthetic industrial gear oil with friction-reducing properties of type CLP 220. Shredding waste wood is a hot topic, but a highly efficient radiator geometry of the Doppstadt Shredder ensures demand-oriented cooling despite the narrow installation space. However, the gearboxes and their oils have to cope with a whole range of other challenges. The machines often operate in an extremely dirty environment. Just like water, which occurs as condensation due to often high humidity, dust can enter the lubrication circuit despite an oil-resistant sealing system. In addition, there are impacts and vibrations up to the maximum torque.

Whenever a mobile INVENTHOR or stationary CERON shredder is serviced, the Doppstadt technicians take a sample of the gear oil and send it to OELCHECK for analysis. The condition of the gear oil is examined in the laboratory. Any impurities, such as water, dust or sealing materials, are detected in the same way as oil oxidation due to excessive temperature or elements as an indication of impending wear. The laboratory reports with informative comments from OELCHECK tribologists provide Doppstadt technicians with important information. Based on this, the oil change intervals of the individual gearboxes are adjusted. In addition, the laboratory reports with comments allow conclusions to be drawn about the necessary repair requirements for the gearboxes. The operational safety of the systems is a top priority at Doppstadt. After all, operators should be able to rely on the everyday use of their machines. Regular maintenance of the machines is essential for this, because unplanned downtime or even damage can be minimised or completely prevented.

Service packages tailored precisely to the needs of customers ensure that no inspection is forgotten in day-to-day business and downtime is reduced to a minimum. In addition, there is worldwide security of supply, fast repair service on site and all-round carefree packages as part of service and maintenance contracts. Because Doppstadt knows: “Every machine is only as good as the service behind it.”

Smart recycling solutions and products

Founded in 1965 by Werner Doppstadt in Velbert as an agricultural business, the family-run company is today a world-leading, recognised partner in environmental technology. Approx. 700 employees plan, implement and manufacture systems and shredding technology for mobile and stationary use, which are used for the processing of a wide range of materials. The company’s employees share a passion for environmental technology and the aspiration to find ever better and more sustainable solutions for customers. This results in resource-saving, economical and innovative products as well as the best possible personal service.

For further information: www.doppstadt.de