The company has been setting the standard since 1985, with the development of ever larger and thus more efficient turbines. Today, there are more than 6,000 Nordex wind turbines turning in 38 countries, with a total power rating of more than 12,200 megawatts. The company’s wind turbines have an impressive technical availability of 98 percent! And this is going up, because the company is constantly increasing the quality and thus the efficiency of its turbines.

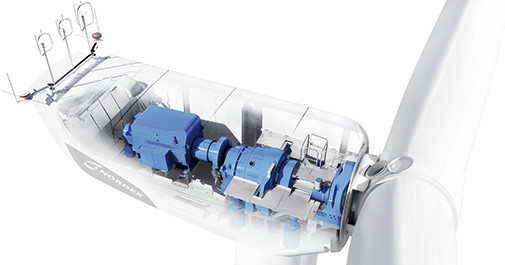

Lubricants for wind turbines are also closely examined here. Gear oil plays a very special role. Nordex has always relied on drive trains with gears. This design has proven to be the best from a technical point of view. The gearbox converts the rotor’s low rotational speed of around 15 RPM to the electricity generator’s high speed of 1,200 RPM. The gearbox of the latest generation of turbines, Gamma, weighs about as much as 17 small cars and must be designed to convert around nine times the power. The torque achieved at the nominal capacity of a turbine is equivalent to the weight of 150 small cars hanging at arm’s length on the gear shaft.

Nordex experts place great emphasis on selected gear oils that are only approved if they meet our high standards. Where mineral oil-based products were previously used, wind turbines are now generally filled with a fully synthetic, high performance gear oil of ISO-VG 320 standard. This extensively tested oil is also recommended for future oil changes for older turbines.

The synthetic gear oil has a whole range of benefits. It is more resistant to oxidation and has greater temperature stability, and distinguishes itself with its multigrade characteristics. At low temperature ranges it is not quite as viscous as mineral oil. This makes it easier to pump and filter. At high temperatures, the oil provides additional safety through a higher-viscosity, stable lubricating film.

A special anti-wear additive significantly exceeds the performance of traditional EP-additives. The special additive technology is activated at high, specific surface pressures and corresponding temperatures in particular. It delivers optimisation of friction partner surfaces and actively protects against wear. Together with the more favourable viscosity-temperature relationship, this achieves an improvement in gear efficiency. But that isn’t the only benefit for turbine operators.

The synthetic lubricant achieves considerably greater durability than mineral oil based products. While, in the experience of Nordex, a mineral oil-based gear oil needs to be changed after 2 1/2 to no more than 3 years, the synthetic lubricant is not expected to be changed until after at least 5 years. With a capacity of 400-650 litres, this effect of the synthetic oil definitely pays for itself despite its slightly higher cost for the operator. Consequently, this results in lower costs for gear oil, maintenance and disposal.

A wind turbine filled with mineral oil-based gear oil is primarily converted to the new synthetic gear oil when maintenance or a regular oil change is due. However, if irregular values are found for a gear oil during a half-yearly OIL CHECK, the turbine can certainly be converted to synthetic oil early. This is particularly the case where the lubricant has aged prematurely and oxidation and additive degeneration, amongst other things, are seen on the IR spectrum.

Selected service companies that also perform maintenance on turbines in various wind farms carry out the conversion to the new synthetic gear oil. They carry out the work precisely to the specifications of Nordex. After draining the used oil at operating temperature, the gearbox and the cooling circuit for the oil is thoroughly rinsed. The oil that is not drained into reservoirs in bearings and ribbing is sucked out using special lances. The fresh synthetic oil then used to fill the turbine should not contain any more than 3% of the old mineral oil. Synthetic oil can also only perform to its maximum potential if it is unmixed. On the other hand, the more powerful cleaning effect of the synthetic oil could dissolve any sludge deposits that the mineral oil could not remove. However, if these sludge deposits do enter the overall lubrication system with the oil, the filters will be able to block them more quickly. In a worst case scenario, the lubricant supply lines in the bearings can be blocked by deposits, causing bearing failures and then gear damage.

So that operators are absolutely on the safe side, Nordex requires written proof in the form of a laboratory report that the requirement of less than 3% residual oil has been adhered to when the oil is changed. This is easy to do using the analysis sets designed by OELCHECK specifically for Nordex wind turbines. The proven Nordex analysis sets have been a permanent fixture in our maintenance concept for years. Before a turbine converted to the new synthetic gear oil re-enters operation, a "zero sample" is sent to OELCHECK. For this, "Oil change" is simply ticked on the shipping note.

Then, in the OELCHECK laboratory, values such as viscosity, wear, impurities and additives are determined, but not only these. As well as specific wave number ranges in the IR spectrum, the residual content of the previously used product in the fresh oil can also be determined precisely, amongst other things, by using its density. If it is under the limit of 3% and everything else is in order, the go-ahead is given for the further operation of the Nordex wind turbine, which will be more efficient thanks to the new synthetic gear oil.

Nordex, with its headquarters in Hamburg and its main production site in Rostock, is one of the world’s leading manufacturers of on-shore wind turbines. The company’s areas of expertise include developing and manufacturing wind turbines, constructing ready to use wind farms and maintenance and service. With its Delta generation, Nordex is offering the fourth generation of its proven multi-megawatt platform. With larger rotors, an increased power rating and optimised technical systems, the Delta generation sets new standards in terms of cost, reliability, ease of service and work safety.

related links