![[Translate to "English"] Europe-wide service around the clock [Translate to "English"] Europe-wide service around the clock](/fileadmin/_processed_/a/b/csm_TEDOM-SCHNELL_Service_Mitarbeiter_ea4dd199d5.jpg)

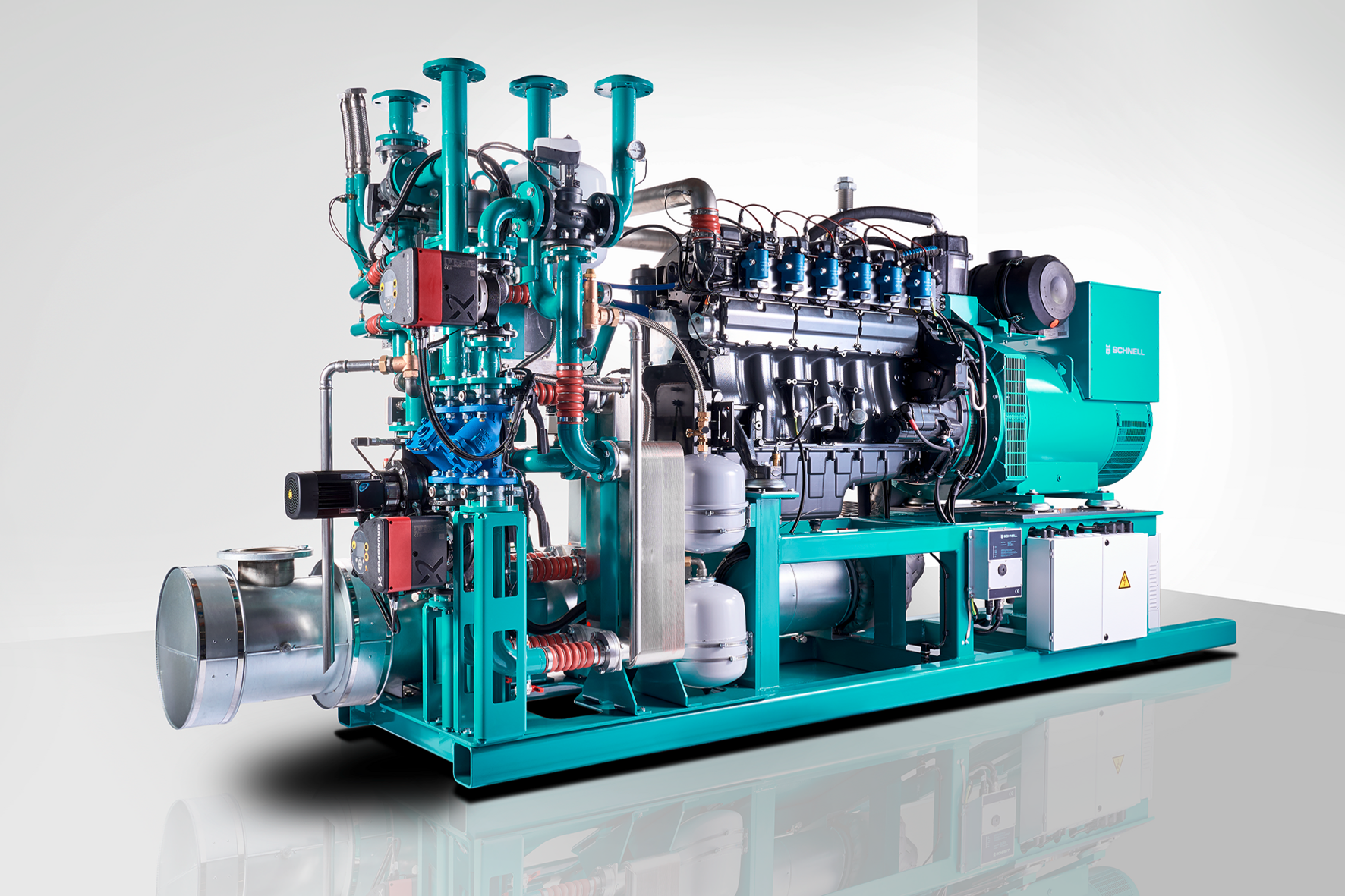

TEDOM SCHNELL GmbH, based in Wangen/Allgäu, is a manufacturer of combined heat and power plants (CHP) for decentralised generation of electricity and heat. The highly efficient CHP solutions run on natural gas, biogas or sewage gas and function according to the principle of combined heat and power generation. Once the project has been planned and the facilities constructed, the company's own strong service fleet is available to operators around the clock.

TEDOM SCHNELL has one of the largest service networks for CHP plants in Germany. OELCHECK analyses of gas engine oils and coolants optimise condition monitoring in the facilities. This ensures reliable and efficient energy supply in the long term.

TEDOM SCHNELL CHP solutions utilise the full capacity of primary energy through highly efficient generation of electrical and thermal energy. The company's 4,100 CHPs already installed are used throughout Europe in biogas plants and landfills as well as for industrial, commercial and municipal energy supply. The different designs, such as compact modules, in containers or in a turbine building, are tailored to individual requirements.

The company's technical developments are trend-setting. Previously it was the “Schnell dual fuel engine”, now it’s the “passive prechamber” that is setting new standards.

The dual fuel engine is based on the diesel principle. But when operated with biogas, sewage gas or landfill gas, the dual fuel engine can do even more. Gases can be more compressed than diesel fuel, for example. The gas is mixed with the combustion air drawn in. The mixture of gas and oxygen-containing air is compressed in the engine and heats up in the process. Injecting a small amount of ignition oil (heating oil/diesel fuel) initiates the ignition. The higher compression ratio of the gas-air mixture increases efficiency. Higher efficiency means higher energy yield. To achieve this, the intelligent Schnell injection technology for dual fuel engines was developed.

Biogas, sewage gas and landfill gas often change their composition in a short time. Values such as knock resistance and flame rate can double or halve in seconds. These changing conditions are controlled with the Schnell dual fuel technology. This is based on sophisticated electronic injection technology for optimum control of ignition timing – a milestone in the history of dual fuel technology.

TEDOM SCHNELL's new passive prechamber is revolutionising the CHP technology of the future. The fuel-gas/air mixture is already ignited in the prechamber by a specially matched industrial spark plug. This results in an increase in pressure, which drives the ignited mixture far into the main combustion chamber in several torch jets. The result is fast and efficient combustion with low emissions. For robustness, reliability and long service life of the prechamber and spark plug, TEDOM SCHNELL’s new development is better than anything currently available on the market.

TEDOM SCHNELL ensures that facilities operate without problems and profitably through a comprehensive range of services. This starts with the first consultation and does not stop at maintenance and repair. Over 300 service technicians and partners throughout Europe are available around the clock. These are all fully trained and certified. TEDOM SCHNELL operates one of the largest service networks for CHP plants in Germany, and it is continuously being expanded with new service locations.

TEDOM SCHNELL knows how crucial lubricants and coolants are for systems to run safely and efficiently. The company therefore offers its own tailor-made consumables. These were developed with TEDOM SCHNELL’s many years of experience in gas engines and the expertise of renowned lubricant manufacturers.

TEDOM SCHNELL PROTECT OIL is recommended for all CHPs installed by the company. Thanks to its selected base oils and unique high-performance additives, it achieves the highest level of wear protection and stability even under the toughest operating conditions. Its extremely low tendency to form deposits means engines remain clean. TEDOM SCHNELL PROTECT OIL has a very large alkaline reserve. This allows it to neutralise the typical aggressive acids from biogas, sewage gas and landfill gas over a particularly long period of time. The gas engine oil is extremely resistant to thermal oxidation and is therefore also ideal for use in CHP plants running on natural gas, which operate at extremely high temperatures.

TEDOM SCHNELL PROTECT COOLANT is a ready-mix coolant for engines. The preprepared mixture can be used immediately. This means that operators are always on the safe side and save time and money. The coolant is precisely matched to the materials of engine and attachments. Thanks to the ideal mixing ratio, the anti-corrosion and buffer additives are used optimally and the components are protected over the long term. The decalcified and extremely soft make-up water prevents the formation of encrusted deposits and the damage these cause.

Regular inspections of the gas engine oil are important. Right from the purchase of a system, TEDOM SCHNELL offers a certain number of free OELCHECK oil analyses and inexpensive follow-up analyses. Engines that run on biogas, sewage gas or landfill gas in particular are using a gas where the composition can vary greatly. Such gases also often contain aggressive or acidic components such as hydrogen sulphide.

TEDOM SCHNELL PROTECT OIL is perfectly designed to meet such requirements but, depending on the gas composition, even its performance is eventually exhausted under these extreme loads. Two to four OELCHECK analyses are carried out for every engine oil fill per year and also at every maintenance. These meticulously record the condition of the gas engine oil. OELCHECK tribologists also state in their laboratory reports how long the oil in question can still be used safely under similar operating conditions. Monitored in this way, in many cases TEDOM SCHNELL PROTECT OIL achieves oil change intervals of almost 1,000 hours of operation. Without accompanying oil analyses, TEDOM SCHNELL stipulates oil changes after 600 operating hours.

Two at once – TEDOM SCHNELL lists the OELCHECK all-inclusive kits for gas engines in its own spare parts programme. This enables the analysis of engine oils, regardless of the gas they run on, and of coolants. Like many other OEMs, TEDOM SCHNELL specifies that coolant must be examined once a year. If OELCHECK analyses are consistently good, the coolant change interval can often be extended to two years.

The all-inclusive analysis kit with a turquoise-coloured lid covers the full check scope. For each analysis, the acid-base content of the oil in particular is checked. The acid number (AN) indicates the degree of acidification of the oil. The base number (BN) provides information on the base additives still present to neutralise the acids. OELCHECK also measures the i-pH value, as this provides key additional information on the loading of a used gas engine oil with corrosive acids.

Fast and secure – Thanks to the OELCHECK app 4.0 and QR codes attached to equipment, operators and TEDOM SCHNELL service technicians now save even more valuable working time when entering samples and transmitting data. They only enter the operating hours of the current sample, add any information about work carried out and any abnormalities and scan the barcode on the sample information form, which is identical to the laboratory number they affixed to the sample container. The app then transmits the data to OELCHECK. The smart combination of QR codes and app means all important data is captured. Transmission errors due to poorly legible handwritten entries on the sample information forms are a thing of the past.

Everything under control – The LAB.REPORT web portal is where the data from all analyses initiated by TEDOM SCHNELL and the plant operators (with corresponding approval in accordance with the GDPR) come together. This gives TEDOM SCHNELL a broad overview of all trends, contributing directly to perfect quality management. For plant operators, the web portal not only provides quick access and easy management of their analytical data. It also makes it easier to monitor the systems and document that the OELCHECK analyses recommended by TEDOM SCHNELL have been carried out regularly.