his is the approach across all areas of the company. The 'Oil analysis before maintenance/inspection' project exemplifies this. In conjunction with the introduction of extended oil change intervals, OELCHECK lubricant analyses have been carried out on hundreds of the company's oil-lubricated sheet offset printing presses since 2015.

The result – oil service life has been significantly extended for 73% of these printing presses! A real boon for customers and the environment.

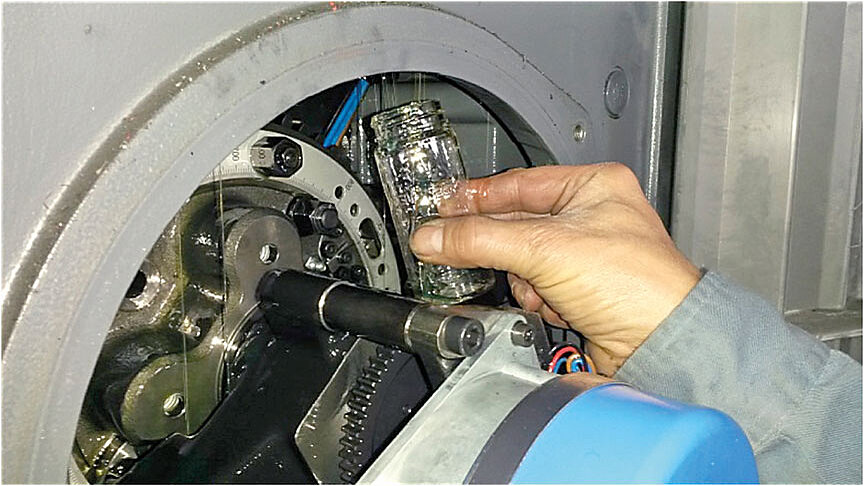

A CLP 150-type mineral oil-based industrial gear oil is usually used to lubricate printing presses. Depending on the type of press and number of print works, between 50 and 150 litres of gear oil are required.

If the oil was previously usually changed every year in the Heidelberg printing presses, it can now mostly be used for much longer thanks to the oil analyses. The customers' feedback is entirely positive. In some companies, costs for procuring and disposing of lubricants decreased dramatically, as did maintenance outlay. In total, the Heidelberg customers save the environment from several thousand litres of lubricating oil each year with the help of the state-based extended oil change intervals.

Since Heidelberg had had good experiences in Germany with the lubricant analyses from OELCHECK for many years, and with the 'Oil analysis before maintenance/inspection' project since 2015, the partnership between the companies was also trialled in France and the UK. Following extremely positive feedback from customers, Heidelberg has used the lubricant analyses carried out at OELCHECK in Germany since 2016 across the board in all machine types with circulating oil lubrication.

Accordingly, Heidelberg business units operating abroad now also enjoy the benefits of OELCHECK lubricant analyses:

Thanks to the 'Oil analysis before maintenance/inspection' project and the partnership with OELCHECK, Heidelberg has been able to improve the service it offers its customers significantly!

Heidelberger Druckmaschinen AG is a market and technology leader in the printing industry, known for its sheet offset printing presses and solutions for the print media and packaging industry. User-friendly systems, custom products and innovative services ensure the highest degree of product quality, streamline the management of complex processes and help to avoid errors – throughout the production chain.

The result: efficiency at the touch of a button. A total of around 11,500 staff, together with sales partners at 250 locations in 170 countries worldwide, ensure customers' wishes are implemented and constant development on the market. In the financial year 2016/2017, group sales were an impressive €2.5 billion.

related links